Glowplug, Installation of the carburetor – O.S. Engines 12XZ Speed Spec II User Manual

Page 8

14

GLOWPLUG

The role of the glowplug

Glowplug life

Particularly in the case of very high performance

engines, glowplugs must be regarded as expendable

items. However, plug life can be extended and engine

performance maintained by careful use, i.e.:

Install a plug suitable for the engine.

Use fuel containing a moderate percentage of

nitromethane unless more is essential for racing events.

Do not run the engine too lean and do not leave the

battery connected while adjusting the needle.

With a glowplug engine, ignition is initiated by the

application of a 1.5-volt power source. When the

battery is disconnected, the heat retained within the

combustion chamber remains sufficient to keep the

plug filament glowing, thereby continuing to keep the

engine running. Ignition timing is 'automatic' : under

reduced load, allowing higher rpm, the plug becomes

hotter and, appropriately, fires the fuel/air charge

earlier; conversely, at reduced rpm, the plug become

cooler and ignition is retarded.

Apart from when actually burned out, a plug may

need to be replaced because it no longer delivers its

best performance, such as when:

When to replace the glowplug

Filament surface has roughened and turned white.

Filament coil has become distorted.

Foreign matter has adhered to filament or plug

body has corroded.

Engine tends to cut out when idling.

Starting qualities deteriorate.

Since the compatibility of the glowplug

and fuel may have a marked effect on

performance and reliability, it is suggested

to use the O.S. RP6 plug when it is

necessary to replace. Carefully install

plug finger-tight, before final tightening

with the correct size plug wrench.

15

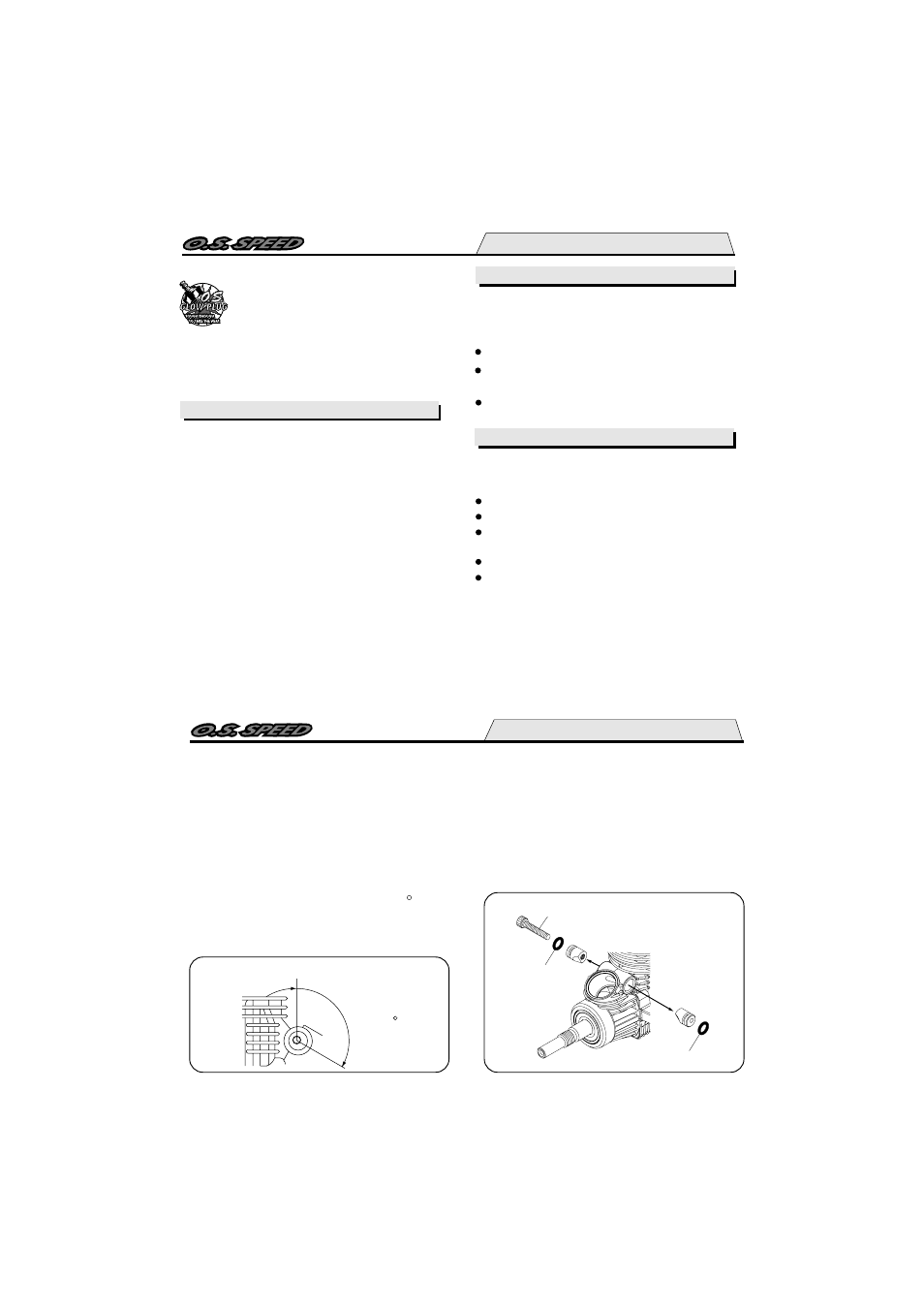

INSTALLATION OF THE CARBURETOR

As delivered, the engine has its carburetor lightly

installed in the intake boss. Secure it as follows.

Loosen the retainer screw, rotate the

carburetor to its correct position and make

sure that it is pressed well down into the

intake boss, compressing the rubber gasket,

before retightening screw.

1.

2.

Rotate the retainer nut

gently until it stops.

Tighten a further

120-180

Rotate the retainer screw gently until it

stops, then tighten a further 120-180 .

Do not overtighten the screw as this will

damage the thermo insulator.

Note

Be careful not to damage the O rings when

removing the carburetor retainer from the

engine.

First, remove the retainer Retaining screw,

then pull out each part. Do not push the

part in or damage the O rings.

Retaining Screw

"O" Ring

"O" Ring