Drive belts, Main broom adjustment, Side broom belt adjustment – Clarke ALTO 28G User Manual

Page 3: Friction drive wheel, Engine speed adjustment (model 28g), Installation of new main brush

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 13

Drive Belts

WARNING: To prevent injury always stop the

engine or motor before doing any

maintenance or repairs to this ma-

chine.

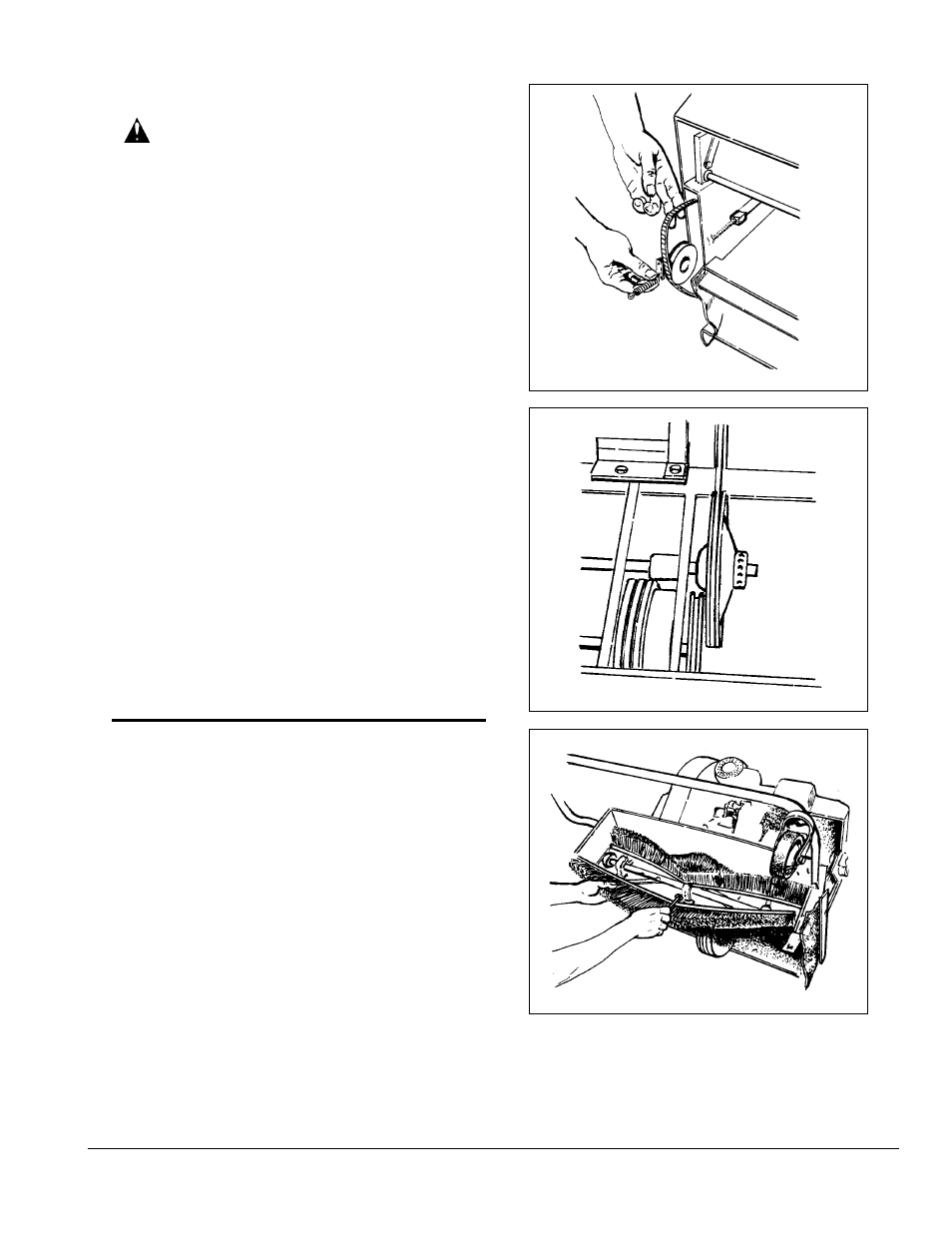

The drive belts are automatically tensioned by a spring-

loaded idler wheel. (See Fig. 9)

1.

Remove the idler pulley tension spring.

2.

Slip the belt off the pulley.

3.

Install a new belt.

4.

Assemble idler tension spring.

5.

Align pulleys and belts if necessary.

Main Broom Adjustment

The main broom should be periodically readjusted as

needed to compensate for wear. Use the broom-adjusting

lever to accomplish this. rotate counterclockwise to lower

and clockwise to raise. (See Fig. 2, page 6)

Side Broom Belt Adjustment

To increase tension on the side broom belt, loosen the two

(2) socket set screws. Push the split clamp forward on the

tubular frame until belt is sufficiently tight to drive broom

without slipping. Tighten clamp screws.

Friction Drive Wheel

The friction drive wheel should be adjusted so it touches the

mating drive wheel. The machine should NOT creep or

move when the operator handle is in neutral "UP" position.

(See Fig. 10)

ENGINE SPEED ADJUSTMENT (Model 28G)

The engine speed (rpm) is governor-controlled and preset

at the factory at 2150 rpm (no load). Should it be necessary

to check or readjust this setting, use a good strobe

tachometer and adjust the governor rod threaded end to

maintain 2150 rpm (no load). Be certain all brooms are

raised for this adjustment.

Installation of new Main Brush

The main brush is made up of five (5) bristle strips, installed

and retained on the core by three (3) screws and washers

for each strip. Do not change (1) new bristle strip with (4)

worn strips.

Remove the three screws and washers and the bristle strip

retained by them. Install the new strip and assemble the

retaining screws and washers. Be sure to install the "V" of

each strip in the same relation to the core as its companion

strips. (See Fig. 11)

Fig. 9

Fig. 10

Fig. 11