Milwaukee Tool 9672-20 User Manual

Page 7

page 7

WARNING!

To reduce the risk of injury, do not use any grease or

lubricant on braking surfaces. The brake is designed

to operate dry. Using any grease or lubricant on the

braking surfaces will cause brake slippage and loss

of load control which may result in injury and/or

property damage.

The brake is designed to operate dry. Do not use any grease or lubricant

on the braking surfaces. When lubricating parts adjacent to the brake,

do not use an excessive amount of lubricant which could seep onto the

brake surfaces.

When the hoist is disassembled for periodic inspections, check the

pawl for free movement and apply a light coat of spray lubricant such

as WD-40 (WD-40 Co.) or equivalent, to the pawl stud. When the hoist is

disassembled for cleaning or repairs, the following locations should be

lubricated using approximately 1 oz. (29.5ml) per hoist of Extreme Pres-

sure Grease such as Molykote BR-2-S (Dow Corning Corp.) or equivalent:

Threads of handwheel, gears, liftwheel rollers, gear bearing roll-

ers, journals of chain guide and dead end pin, sheave wheel rollers

(3 and 5 ton), hook bearing balls (3 and 5 ton), hook collar journals

(3 and 5 ton) and dead end stud (3 and 5 ton).

NOTE: To assure extra long life and top performance, be sure to lubri-

cate the various parts of the hoist using the lubricants specified.

Assembly

Particular attention must be given to the following when assembling the

hoist:

1.

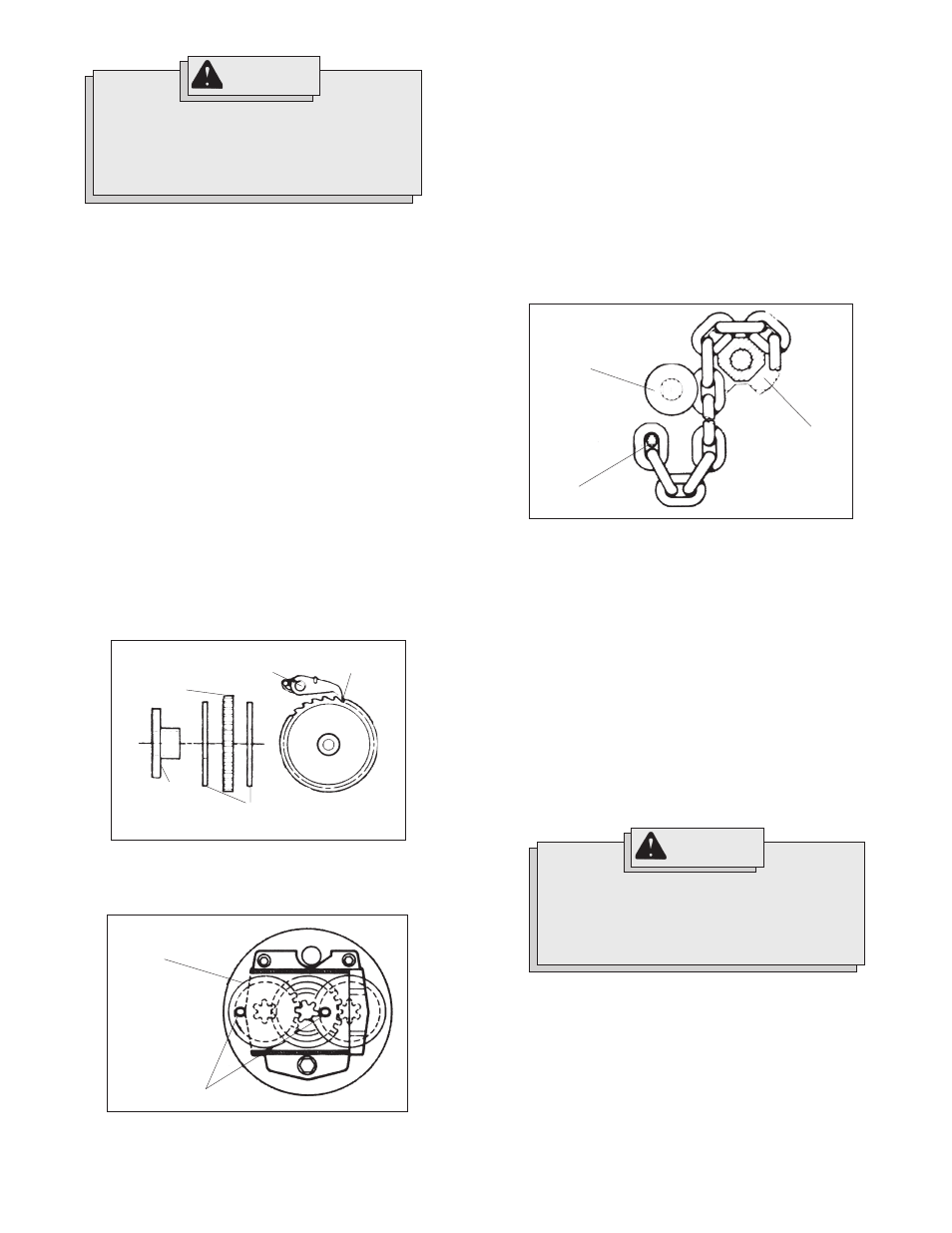

Assemble the brake components as shown in Fig. 6. The ratchet teeth

must face as shown and engage the pawl. Do not lubricate the brake

surfaces. The brake operates dry. Assemble handwheel to pinion shaft

and turn handwheel to seat brake components. Assemble the pinion

shaft nut to the shaft until the nut bottoms. Then back nut off at least

one but not more than two flats. Insert cotter pin and bend ends to

secure same.

2.

The intermediate gears have timing marks (letter "O" stamped on one

tooth). The gears must be assembled with these marks orientated as

shown in Fig. 7.

1.

Attach approximately 20" (508 mm) of soft wire to the loose end of

the chain. Pass the wire over the top of the liftwheel and down

between the liftwheel and the chain guide.

2.

Position the chain so that the first, as well as the third link stands on

edge with the weld away from the liftwheel and the second link lays

flat on the liftwheel.

3.

After the chain has been started, pull hand chain in the hoisting

direction until about 2 feet (0.6 M) of chain has passed over the

liftwheel. The wire should now be removed from the chain.

4.

Remove the cotter pin from the loose end pin and slide the loose end

pin to the side into the gear housing, leaving approximately 1/2"

(12.7 mm) of the pin protruding from the geared side plate.

5.

Loop the chain making sure there are no twists up to the loose end

pin and slide the pin through the last link of the chain. Slide the loose

end pin into the hole in the handwheel side plate until the cotter pin

hole is visible.

6.

Secure the loose end pin by reinstalling the cotter pin and spreading

the legs of the cotter pin.

Ratchet

Friction

hub

Friction

washer

*Pawl

Ratchet

*1/2 ton hoist has 2 pawls set 180° apart

Fig. 6

3.

For proper operation, the correct number of rollers must be installed

at the rotating points of the liftwheel, intermediate gears and hook

block sheave (3 and 5 ton). The correct number of bearing balls

must be installed in the hook collar to retain the hook and insure

proper loading. Refer to Fig. 3 for the correct number of bearing

balls/rollers at these locations. Applying an Extreme Pressure grease

such as Molykote BR-2-S (Dow Corning Corp.) or equivalent to the

rollers or bearing balls will help hold them in position during assem-

bly.

4.

When assembling the latch to the hook, the end of the rivet must be

peened over. When peening over the rivet, apply only enough force

to form the head and retain the rivet. Excessive force will deform the

latch and make the latch inoperable.

Reeving Load Chain

1/2, 1, 2, 3 and 5 Ton Hand Chain Hoists

Chain guide

Loose end pin

Liftwheel

Fig. 8

WARNING!

To reduce the risk of injury, feed load chain

between liftwheel and chain guide before attach-

ing it to the loose end pin. Failure to properly

install the load chain may cause the chain to lift

out of the liftwheel pockets and allow the load to

drop.

Intermediate gear

Timing marks

Fig. 7