Milwaukee Tool 5243 User Manual

Page 5

8

9

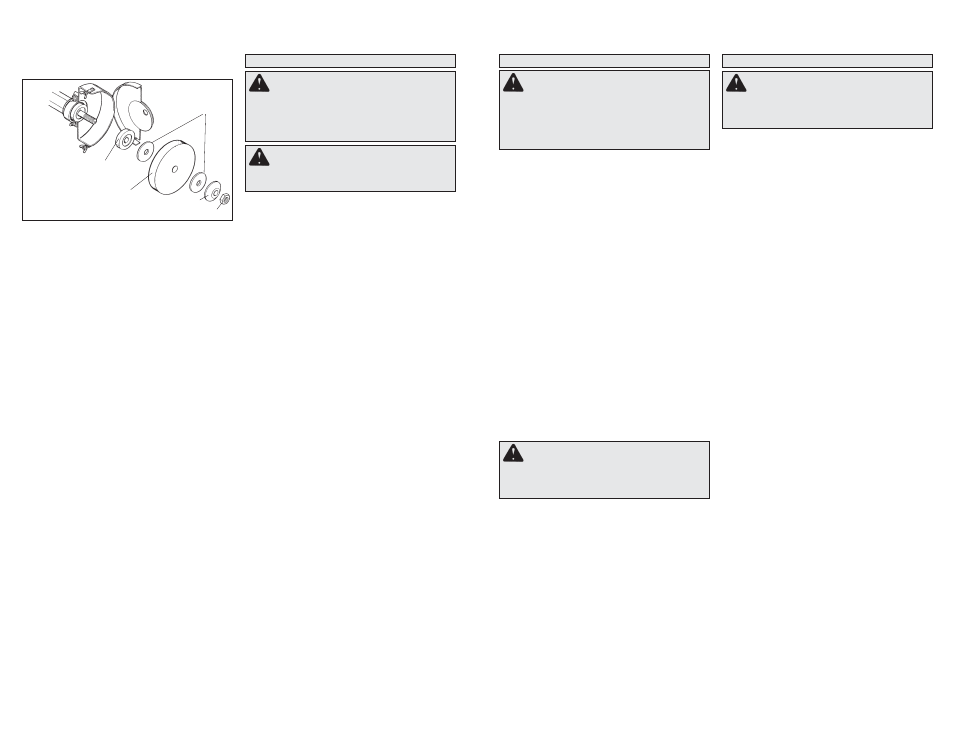

Fig. 6

Inner fl ange

Rubber

washer

Grinding wheel

Outer fl ange

Spindle nut

Installing Grinding Wheels and Accessories

(Cat. No. 5243 only)

1. Unplug tool and lay it on its tool rest.

2. Loosen wing nuts. Move studs aside and swing

the faceplate away.

3. Hold inner fl ange with spanner wrench provided

with the tool.

4. Remove the spindle nut with the 1-1/16" wrench

provided with the tool.

5. Remove outer flange, rubber washer, and

wheel.

6. Examine both fl anges to ensure that they are

free of nicks and are fl at (see Fig. 4).

NOTE: If the fl ange faces are nicked, or if the

inner surfaces of the fl anges are not fl at, then

replace them with identical replacement parts.

On Cat. No. 5243, the fl anges should evenly

contact the rubber washers on either side of the

wheel.

7. If you are installing a grinding wheel, inspect and

test it for damage (see "To Test the Wheel").

8. Place the accessory on the spindle.

Never force an accessory onto the spindle. A

forced fi t may damage the accessory.

9. Replace rubber washer, outer fl ange, and spindle

nut.

10.Tighten spindle nut. Do not overtighten.

11.Swing the faceplate back into place. Move studs

back into slots. Tighten wing nuts.

OPERATION

WARNING

To reduce the risk of injury,

wear safety goggles or glasses with side

shields.

WARNING

To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

Starting and Stopping the Tool

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger.

Using the Trigger Lock Mechanism

The lock button holds the trigger in the 'ON' position

for continuous use.

1. To lock the trigger, hold the lock button in while

pulling the trigger. Then, release the trigger.

2. To unlock the trigger, pull the trigger and release.

The lock button will pop out.

Grinding

1. Hold handle and spindle housing fi rmly.

2. Pull trigger.

3. Allow tool to reach full speed.

Always test new wheels for cracks or damage.

To test new wheels, point the grinder away from

you and shield bystanders from the tool, and then

run the motor at full speed for one minute while

allowing the wheel to spin.

4. Gently apply grinder to the workpiece.

MAINTENANCE

WARNING

To reduce the risk of

injury, always unplug your tool before

performing any maintenance. Never disas-

semble the tool or try to do any rewiring

on the tool’s electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, bro-

ken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. Tag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not neces-

sary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears,

spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electri-

cal operation

WARNING

To reduce the risk of injury,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid

to fl ow inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thin-

ner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

ACCESSORIES

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

WARNING

To reduce the risk of injury,

always unplug the tool before attaching

or removing accessories. Use only specifi -

cally recommended accessories. Others may

be hazardous.