Operation, Maintenance, General – Leslie Controls DIAPHRAGM ACTUATOR 135(R) User Manual

Page 3: Direct actuator disassembly, Direct actuator reassembly, Caution

3

starts to move. Take that air pressure and multiply

it by area of actuator (see Table 1) in order to

obtain the force output of spring.

5.

Repeat steps 1-4 until desired load is reached.

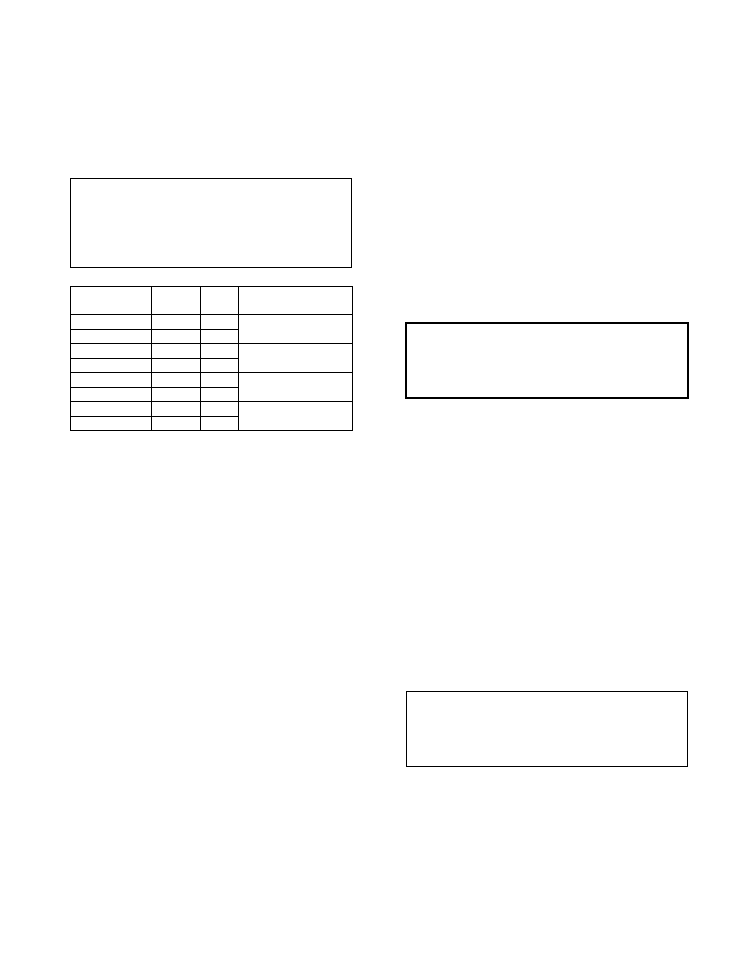

Actuator Size

Stroke

(in)

Area

(in

2

)

Spring Adjustor Rod

Dia. (in)

35

3/4

34

35R

3/4

31

3/4

55

1

57

55R

1

54

7/8

85

2

90

85R

2

87

0.745

135

3

135

135R

3

131

0.995

Table 1- Actuator Load Parameters

OPERATION

Once actuator stroke and spring load have been adjusted,

equipment can be placed into operation. Route air supply

from control system to actuator. Ensure that instrument air

is being used to operate actuator. See equipment instructions

for proper operation of assembly.

MAINTENANCE

General

1.

Remove all air and accessories from actuator prior

to removal from equipment.

2.

Support actuator prior to removing mounting bolts.

For reverse acting actuators apply air to top of

actuator before removing mounting bolts.

3.

Remove actuator mounting bolts.

4.

For direct acting actuators, air may need to be

applied to actuator before removing actuator from

equipment shaft. For reverse acting actuators, air

may need to be removed from actuator. Unscrew

actuator from equipment shaft by either spinning

actuator or unscrewing the shaft. (NOTE: If

actuator is mounted to a valve the valve shaft

must not be turned unless valve plug is lifted off

valve seat!)

5.

Remove all air pressure from actuator and unload

spring tension by grasping actuator stem with a

wrench and unscrewing spring adjustment nut (40).

(see Fig 3)

6.

Actuator is now ready for disassembly.

Direct Actuator Disassembly

(see Fig 1)

1.

Remove nuts/bolts (22/23), upper diaphragm case

(20) and diaphragm (21).

2.

To remove the other components, lift out

diaphragm disc (24) and entire diaphragm disc and

spring (28) assembly will lift out.

3.

Unscrew diaphragm disc nut (16 only showing in

Fig 3) and remove springs (28,29) from the

assembly.

4.

Remove spring adjustment nut (35).

5.

Remove lower diaphragm case screws (26).

Direct Actuator Reassembly

(see Fig 1)

See Torque Values in Table 2

1.

Install lower diaphragm case bolts (26) and torque

to the values given in Table 2.

NOTE

Spring loads will vary if the actuator is mounted on

equipment that does not fully utilize the entire stroke

length of the actuator.

CAUTION!

Spring load must be completely removed before

proceeding or injury/death can occur.

NOTE

Ensure that all the components being installed are free

from any nicks burrs or defects prior to assembly.