Troubleshooting – LABEC Z-L-450 User Manual

Page 12

detergent with distilled water. Don't

sprinkle or spray water on the rotor. Because the stay of liquid will result

in corrosion. To bottom up and dry is allowed after cleaning.

5.1.3.5 Remove the fragment out from centrifugal room with rags or tweezers.

5.1.3.6 Please paint the grease on the spindle motor and connect part between rotor and axle hole.

5.1.3.7 Please cut off the power and unplug the power connected to the backside of the machine before

removing the front shell of the machine. Power operation is not allowed. Prevent electric shock to any people

or damage of the machine.

Note: This operation can only be done by specially trained maintainer from our company.

5.1.3.8 Only accessories provided by our company can be used for this machine.

5.1.3.9 Please cut off the power when you needn't use the centrifuge.

5.1.3.10 The machine is a precision instrument and please keeps it away from moisture, shock, traverse or

rewind.

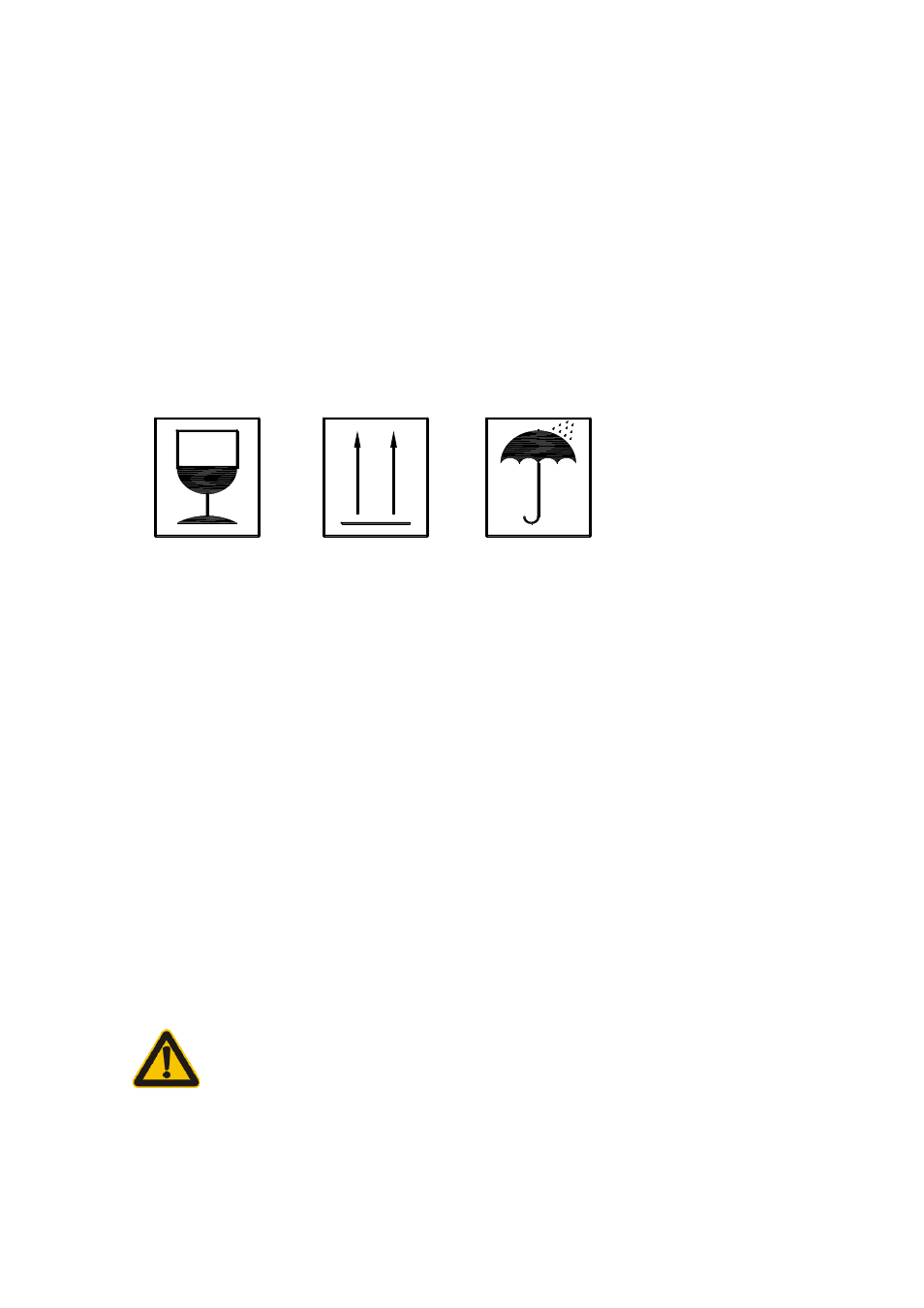

Fragile Upward Moisture-proof

Figure 7: Terms of transportation and storage

5.2 Maintenance responsible by our company.

low-speed table-top centrifuge made by our company will be maintenance once a year by special

maintainer from our company. And the content of maintenance is as following:

l

Examination of electrical part.(Examination of internal circuit functions)

l

Examination of stability of the resettlement of the centrifuge.

l

Examination of electromagnetic locks and other security circuits.

l

Examination of rotor locking device and spindle motor (driveshaft)

l

Maintenance staff clean the rotor and check the performance.

l

our company will charge when they provide on-site repair & maintenance service.

Details of charging amount will be told on the sales contract by both parties.

On the process of maintenance, if we find parts need to be replaced, it will be free of charge if in the

warranty period. Otherwise it will be charged.

6

th

Troubleshooting

6.1 Open the cover in case of emergencies

In the process of normal usage, sometimes there's accidental power failure or fail to open the door, you

can't open the door but you have to remove the samples, in this case, you can open the door cover manually,

and remove the sample. Note: This way can be only used for emergencies. Don’t use it as you like.

When there is power failure, it will take long time to let the rotor stop totally

because rotor hasn't break function when it stops to run. Please wait patiently.

Steps to open the door for emergencies:

6.1.1 Make sure that the rotor stops completely (You can observe that from observe hole of top of door cover)

6.1.2 Cut off the electricity.

6.1.3 There is a plastic plug under the bottom plate of the foreside of the machine; you can pull out the plug