LAARS Mighty Therm AP (Sizes 2000-5000) - Installation, Operation and Maintenance Instructions User Manual

Page 8

Page 8

LAARS Heating Systems

Therefore, the temperature difference between

the inlet and out pipes will be so small as to be

difficult to sense by touching the two pipes.

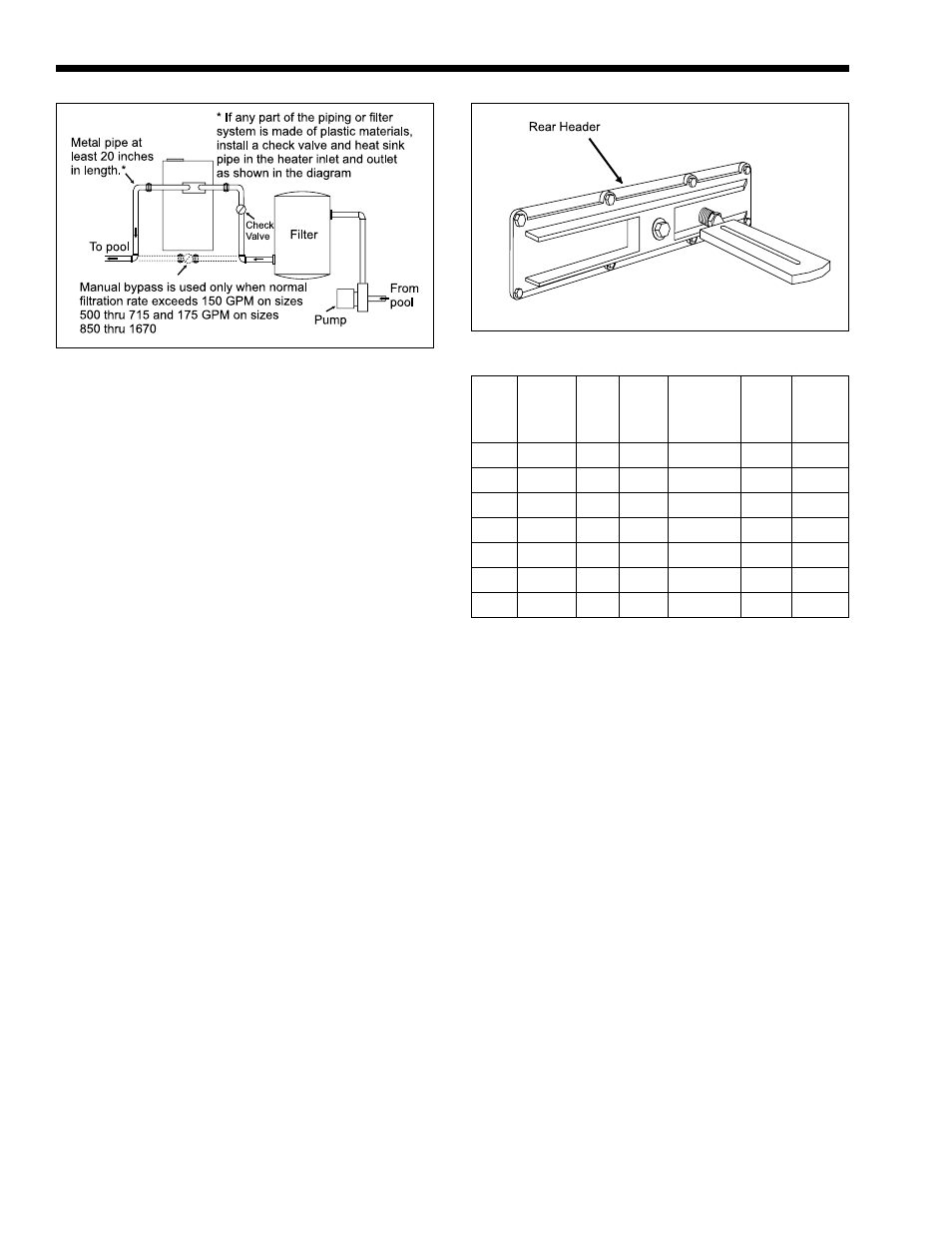

2I. Boiler By-Pass Piping

All Model AP pool boilers are equipped with an

automatic flow control valve. Do not install a manual

bypass valve unless the normal filtration rate exceeds

300 GPM. If the normal filtration rate exceeds that

figure:

1.

Install the manual bypass valve as illustrated in

Figure 7.

2.

Install a thermometer in the threaded opening in

the rear header as shown in Figure 8.

3.

Set the manual bypass valve as follows:

a.

Clean or backwash the filter completely.

b.

Close the manual bypass valve completely.

c.

Close the boiler’s main gas valve.

d.

Start the filtration system with all valves set

for normal filtration.

e.

After 3 minutes, record the thermometer

reading (this is the pool water temperature).

f.

Open main gas valve and turn the

thermostat to its highest setting to start the

boiler.

g.

Gradually open the bypass valve until the

temperature difference shown in column 6

of Table 4 is achieved. For example, if the

temperature reading in Step “e” was 60

degrees, and the boiler is a Model 3500, the

thermometer should read 75 degrees. Make

sure this temperature difference remains

constant for at least 5 minutes.

h.

Remove the handle from the bypass valve

to prevent anyone from changing the

setting. The automatic flow control valve

will maintain proper flow through the

boiler regardless of the reduced water flow

due to a dirty or clogged filter.

2J. Automatic Chlorinators

A concentration of chlorine in the boiler can be

very destructive. Therefore, the following rules

regarding the installation and operation of automatic

chlorinators must be followed.

1.

The chlorinator should be installed so that it

introduces the gas or solution downstream from

the boiler.

2.

The chlorinator should be wired so that it cannot

operate unless the filter pumps running.

3.

The chlorinator should be provided with an anti-

syphoning device so that when the pump shuts

off, chlorine will not syphon back into the boiler.

4.

When the chlorinator is installed in the system

where the chlorine flows through the boiler,

corrosion can occur. Excessive concentrations of

chlorine, caused by improper adjustment or

failure of the chlorination equipment, can cause

boiler damage which is not covered by the

warranty.

2K. Pressure Switch

The pressure switch on the boiler is factory set at

4 psi. Do not tamper with the switch unless the boiler

is installed more than 3 feet below the surface of the

Figure 7. Manual By-Pass Installation.

Figure 8. Thermometer Location.

Bypass

Min.

Max. Temp.

Spring

Flow

Bypass

Rise

Indoor Outdoor Part

Color

Req'd

Valve

at Rear

Size

Size

No.

Code (GPM)Cap. (GPM) Header

2000

------

S220

Black

110

300

15

2450

2200

S221

White

134

300

15

3050

2800

S221

White

167

300

15

3500

3200

S222 Brown

191

300

15

4050

3600

S222 Brown

221

300

15

4500

4000

S222 Brown

246

300

15

5000

4500

S222 Brown

273

300

15

Table 4. By-Pass Valve Adjustments.