9 wiring to current controlled modulating motors, 10wiring to voltage controlled modulating motors, 11wiring the lockout inputs – LAARS MC4EXT - Install and Operating Manual User Manual

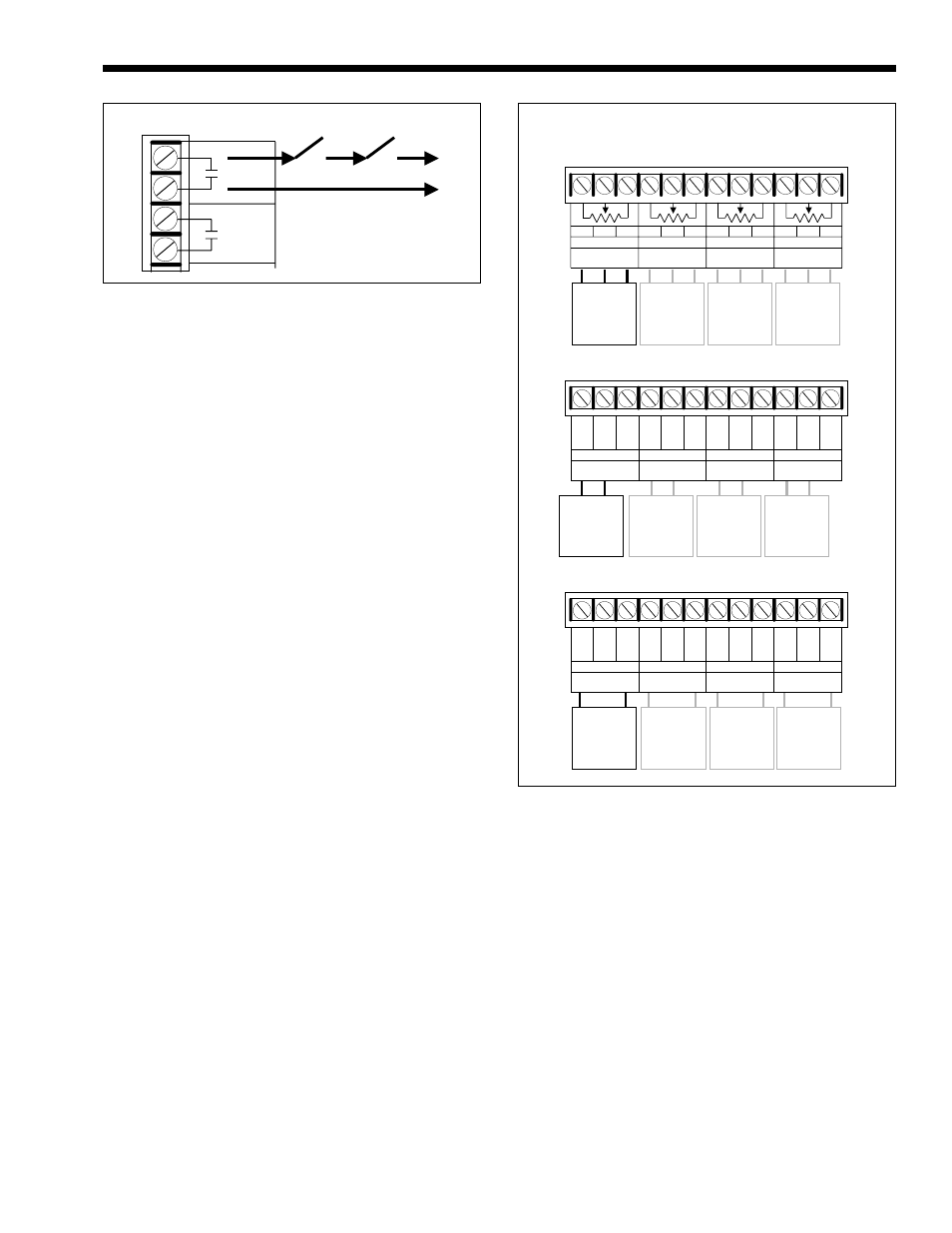

Page 3: Limit circuit typical for each stage

MC Extension Box

Page 3

Class 1 voltages must enter the enclosure

through a different opening from any Class 2 voltage

wiring.

1.8 Wiring to 135

Ω

Ω

Ω

Ω

Ω Modulating Motors

The MCX can be equipped to operate up to eight

135

Ω modulating motors.

Each pair of stages, E&F, G&H, I&J, and K&L,

are controlled by one output board.

Wire as shown in Figure 7 and Table 1.

1.9 Wiring to Current Controlled

Modulating Motors

The MCX can be equipped to operate up to eight

4-20 mA modulating motors.

To program the control for 4-20 mA output, see

the MC I/O manual (MC I/O Manual, System Startup

settings).

Apply the supplied label marked 4-20 mA below

the output terminals.

Each pair of stages, E&F, G&H, I&J, and K&L,

are controlled by one output board.

The MCX sources 24VDC excitation voltage for

the 4-20mA signal.

Wire as shown in Figure 7 and Table 1.

1.10Wiring to Voltage Controlled

Modulating Motors

The EXM can be equipped to operate up to eight

0-5 V, 0-10V, 1-5V, or 2-10V modulating motors.

To select the range, 0-5V, 0-10V, 1-5V or 2-

10V, see the MC I/O manual (MC I/O Manual,

System Startup settings).

Apply the supplied label marked Voltage below

the output terminals.

Each pair of stages, E&F, G&H, I&J, and K&L,

are controlled by one output board.

Wire as shown in Figure 7 and Table 1.

1.11Wiring the Lockout Inputs

A closure across the pair of MCX LOCKOUT

INPUT terminals informs the MC that the particular

stages's boiler, chiller, etc. has encountered a safety

limit and can not be restarted without a manual reset.

The MC will not activate or modulate a Stage in

Lockout.

A pair of LOCKOUT INPUT terminals is

provided for each stage.

The Lockout signal must be a dry contact closure

from the boiler, chiller, etc. controlled by that stage's

output.

The LOCKOUT INPUTS are dry contacts only.

No voltage can be placed across the terminals.

Wire the Lockout signals to their respective

STAGE terminals (see Figure 8):

- STAGE E to Lockout Input terminals B1&B2

- STAGE F to Lockout Input terminals B3&B4

- STAGE G to Lockout Input terminals B5&B6

- STAGE H to Lockout Input terminals B7&B8

- STAGE I to Lockout Input terminals B9&B10

- STAGE J to Lockout Input terminals B11&B12

- STAGE K to Lockout Input terminals B13&B14

- STAGE L to Lockout Input terminals B15&B16

Figure 6. Stage Wiring.

3

4

F

2

E

1

Limit Circuit

Typical for

each stage

Figure 7. Control Voltage Wiring.

B

C2

C3

C4

C5

C6

C7

C8

C9 C10 C11 C12

R

W

B

135

W

Motor

B

R

W

135

W

Motor

B

R

W

135

W

Motor

B

R

W

135

W

Motor

R

W

135

W

E

B

R

W

135

W

F

B

R

W

135

W

G

B

R

W

135

W

H

4 - 20mA

Motor

Current

E

Current

F

Current

G

-

GND

+

24

NC

Current

H

C1

C2

C3

C4

C5

C6

C7

C8

C9 C10 C11 C12

C1

-

GND

+

24

NC

-

GND

+

24

NC

-

GND

+

24

NC

-

+

4 - 20mA

Motor

-

+

4 - 20mA

Motor

-

+

4 - 20mA

Motor

-

+

Voltage

Motor

Voltage

E

Voltage

F

Voltage

G

V+

NC

GND

Voltage

H

C2

C3

C4

C5

C6

C7

C8

C9 C10 C11 C12

C1

V+

NC

GND

V+

NC

GND

V+

NC

GND

GND

Voltage

Motor

Voltage

Motor

Voltage

Motor

V+

GND

V+

GND

V+

GND

V+