General maintenance – Classen 60-RT User Manual

Page 6

4

GENERAL MAINTENANCE

AERATOR MAINTENANCE

TO KEEP THE AERATOR IN GOOD

OPERATING CONDITION, PERFORM

THE FOLLOWING:

•

When replacement parts are required, use genuine

Classen parts or parts with equivalent characteristics

including type, strength, and material. Failure to do so

may result in product malfunction and possible injury

to the operator and/or bystanders.

•

Any warning decal that becomes illegible should be

replaced immediately. (See Pg. 5.)

•

Do not operate equipment without shield(s) in place.

Do not make any adjustments or perform any

maintenance while the engine is running.

•

Thoroughly clean all tines inside and out when

aerating is completed and apply a light coat of oil to

prevent rust on tines.

•

Always lubricate Aerator each time it is put into

service. Wipe off lubrication fittings before and after

each lubrication. The number of lubrication fittings

vary depending on model of Aerator.

Model CA-18

- Qty 2, one in each rear wheel assembly.

Models TA-19D/TA-26D (water drum models) - Qty 3, one in

each rear wheel assembly and one on the idler/clutch arm pivot

bearing. (See Fig. 2.)

Models TA-19/TA-26 (front tire models) - Qty. 5, one in each

wheel assembly and one on the idler/clutch arm pivot bearing.

(See Fig. 2.)

Models TA-17D/TA-25D - Qty. 4, one in each wheel assembly

and one in each idler/clutch arm pivot bearing. (See Fig. 2.)

•

Check roller chain(s) for tightness. Follow these steps:

Model CA-18

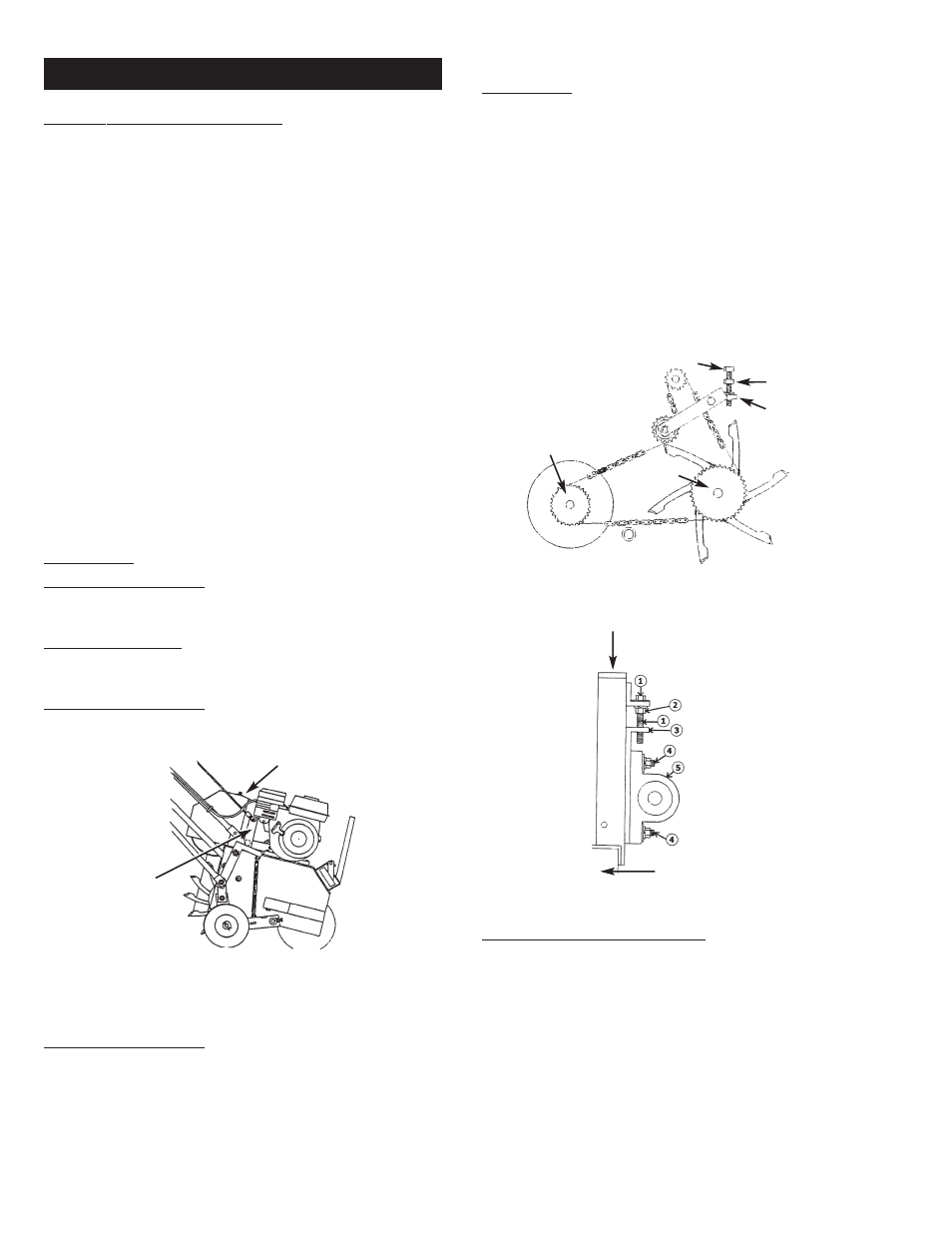

(See Fig.3.)

1.

Disconnect spark plug.

2.

Take off pulley guard by removing two nuts and

lock washers.

3.

Loosen nut (B) by turning counter-clockwise until nut

comes in contact with head of bolt (A).

4.

Tighten bolt (A) until chain is tight between front axle

sprocket (D) and tine assembly sprocket (E).

(See Note Opposite Page)

5.

Retighten nut (B) by turning clockwise against

lock washer (C).

6.

Replace pulley guard, nuts and lock washers and

retighten nuts.

Pulley Guard

Fig. 2

Idler Clutch Arm

(Right Side)

•

Keep drive belt(s) free of oil and dirt.

Models TA-17D/TA-25D

- If belts slip due to normal belt

stretch, engine can be adjusted forward within slotted holes to

tighten belts.

•

Check roller chain(s) for wear. Apply a light coat of

No. 30 oil or penetrating chain lubricant to keep the

chain(s) clean and in proper running order.

A

Fig. 3

B

C

D

E

Fig. 4

Main Frame Top Flat (Left Side)

Main Frame (Left Side)

Model TA-17/TA-19/TA-25/TA-26 (See Fig. 4.)

1.

Disconnect spark plug.

2.

Take off pulley guard (see Fig. 2) by removing bolts,

etc. which attach it to the frame.

3.

Loosen the bolts, nuts, lock washers, and flat washers

(Key 4) to allow movement of the pillow block

bearings only (Key 5). Loosen nuts only, do

not remove.

4.

Loosen and unthread the two 5/16'' nuts (Key 2) down

to top of chain tightening bracket (Key 3).

5.

Turn the tap bolts (Key 1) evenly clockwise so jack

shaft stays level with frame until chain(s) is/are tight.