0 duct design and burner mounting, 0 start-up and adjustment, Figure 7–pressure measurement figure 6–pilot cock – Eclipse Combustion AH User Manual

Page 6

6

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

3.0

Duct Design and Burner Mounting

Duct Design

See Figure 5 for typical mounting arrangements and duct designs.

Support

The mounting flange or brackets supplied with an AH burner are capable of sup-

porting the weight of the burner and blower. The AH burner case itself is de-

signed to support the weight of the blower, so the blower does not require inde-

pendent support.

Valve Train Support

Support valve trains independently of the burner.

Gas Piping

Use flexible nipples to allow for thermal expansion of the burner.

Check Valve Piping

Gas flow through the check valve must be horizontal. See Figure 3.

Gas Piping Standards

Gas piping must comply with American National Standard entitled “National Fuel

Gas Code”* (NFPA No. 54 or ANSI Z223.1), or must be acceptable to the author-

ity having jurisdiction.

Wiring Standards

Electrical wiring must comply with the National Electric Code*, (NFPA Std. 70 or

ANSI-CI 1981), or must be acceptable to the authority having jurisdiction.

*Available from:

National Fire Protection Association

American National Standard Inst.

Batterymarch Park

1430 Broadway

Quincy, MA 02269

New York, New York 10018

4.0

Start-Up And Adjustment

Initial Settings

Adjust the linkage of the gas control valve so that when heat is called for, the

valve is 10° from fully open, and when cooling is required, the valve is approxi-

mately 5° from fully closed.

Close all manual gas cocks.

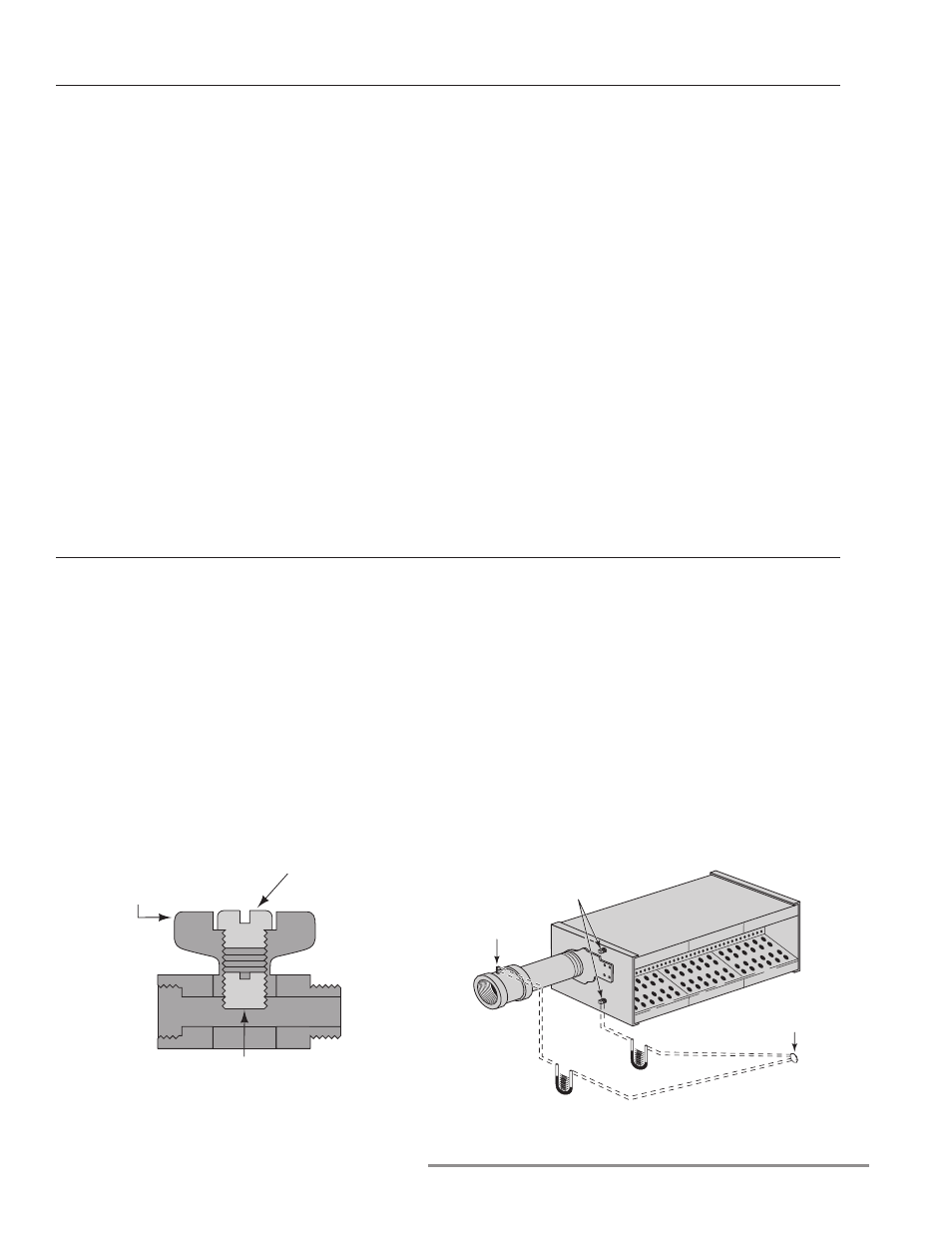

With the pilot cock handle in the closed position, remove the top screw and turn

the adjusting screw five turns out from fully closed. See Figure 6.

Start Blower

Start the combustion air blower on the burner. Check the rotation to make sure it

is correct. If not, have a qualified electrician rewire the blower for proper rotation.

Start Circulating Fan

Start the duct circulating fan.

Figure 7–Pressure Measurement

Figure 6–Pilot Cock

Top Screw

Handle

(Shown in

Open Position)

Adjusting Screw

(Clockwise for less pilot gas,

Counterclockwise for more pilot gas)

Gas

Pressure

Tap

Duct Tap

10" to 20"

Downstream of Burner

Air Pressure

Taps (2)