English-19, Troubleshooting, Symptom problem solution – Coleman Denali 9790 User Manual

Page 20

Troubleshooting

19

English-19

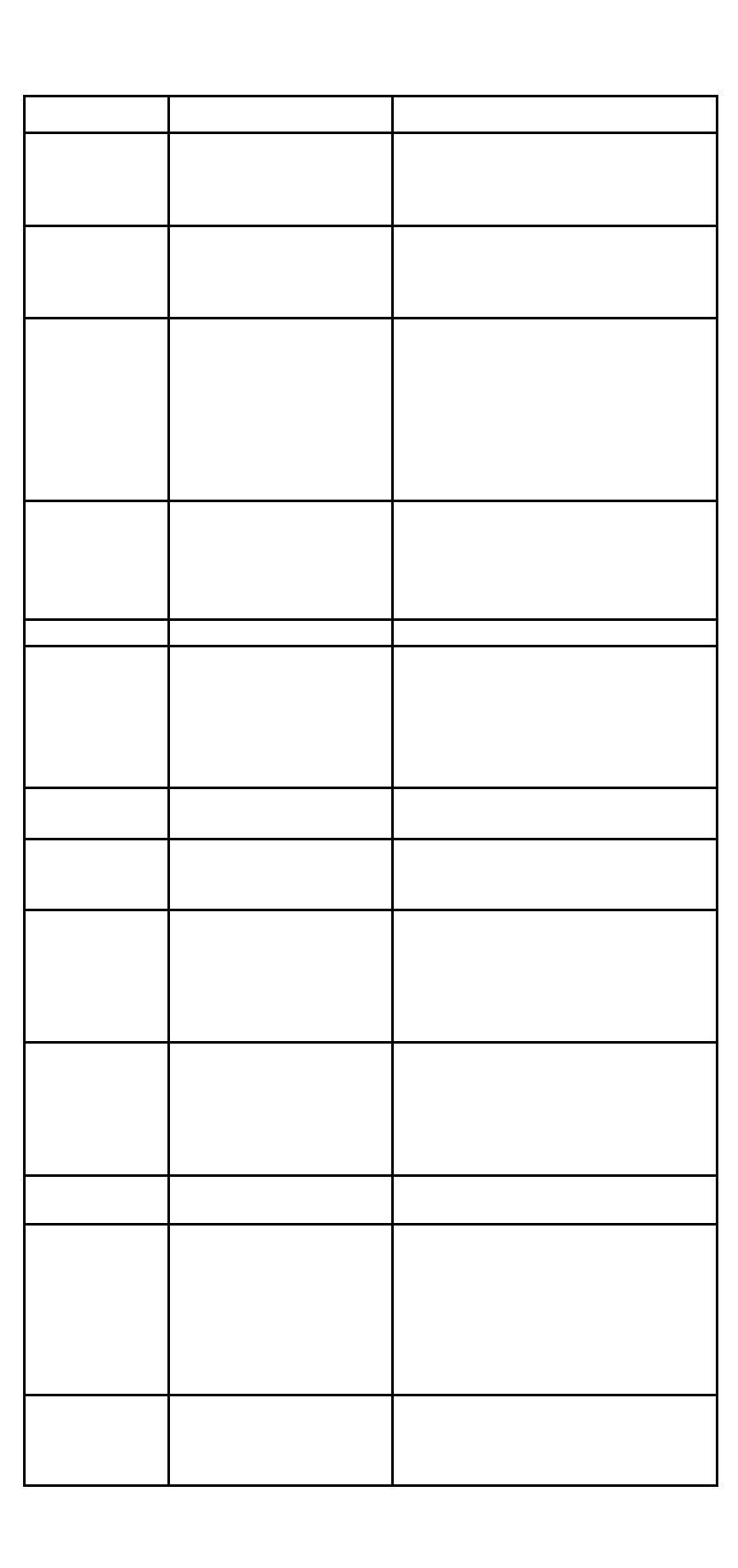

Symptom

Problem

Solution

Burner will not

light or flame

self-

extinguished.

Fuel bottle empty.

Refill fuel bottle 3/4 full with clean and

fresh Coleman® fuel or approved fuels.

Burner will not

light or flame is

low or flame self-

extinguished.

Little or no pressure in fuel

bottle.

Check connections for leaks and pump

20 strokes.

Yellow flame.

Generator not fully

warmed.

A yellow flame is normal until the

generator warms up. If yellow flame

persists, turn off stove, allow flame to

burn until almost extinguished and re-

open fuel valve. Colder weather or

heavy fuels such as Kerosene require

longer preheat time. Follow lighting

instructions.

Low heat.

Gas tip plugged.

Turn flame adjuster back and forth

several times to clean gas tip. Be sure

to use only fresh and clean fuel. If

condition persists, remove gas tip and

use tip-cleaning tool.

Low heat.

Incorrect gas tip.

Confirm gas tip is correct for fuel used.

Low heat.

Faulty generator.

Replace with a new generator. This is

a normal periodic maintenance

procedure. The generator life is

dependent on the type of fuel used.

Generator life is extended by using

clean Coleman® fuel.

Persistent small

yellow flame.

Faulty generator.

Replace with a new generator.

Sputtering yellow

flame then very

high heat.

Incorrect gas tip.

Confirm gas tip is correct for fuel used.

Yellow smoky

flame.

Spider webs, insects, or

other obstruction in the

burner or gas tip.

Remove impingement plate to inspect

and clean the burner. Turn flame

adjuster back and forth several times to

clean gas tip. If system persists,

remove and inspect gas tip (see

Section 4).

Irregular blue

flame.

Gas tip plugged by debris. Remove impingement plate to inspect

and clean the burner. Turn flame

adjuster back and forth several times to

clean gas tip. If symptom persists,

remove and inspect gas tip (see

Section 4).

Irregular blue

flame.

Possible damage to

cleaning needle.

Please contact Consumer Services.

Pump does not

pressurize the

liquid fuel

canister.

Pump seals are dry or

worn.

Squirt a few drops of oil in the OIL

HOLE in the pump cap. This will keep

the pump functioning properly

(Fig. 43). If this does not correct the

problem, replace the pump seals or

purchase a new pump assembly.

Pump does not

pressurize the

liquid fuel

canister.

Pump assembly not fully

seated on liquid fuel

canister.

Check pump seal for damage and hand

tighten pump assembly to liquid fuel

canister.