CatEye CC-ST200 User Manual

Cateye tomo xc, Cyclocomputer model cc-st200

Setting Values Cross Reference Table

(The tire size is marked on both sides of the tire.)

U.S. Pat. Nos. 4636769/4642606/5236759/5226340

and Design Patented

Copyright© 1999 CATEYE Co., Ltd.

CCMSTxch1-991124 Printed in Malaysia 066600035

3

CATEYE TOMO XC

CYCLOCOMPUTER

Model CC-ST200

[with Heavy Duty Wire]

magnet

sporkes

bracket

rubber pad

Fig.1

Fig.8

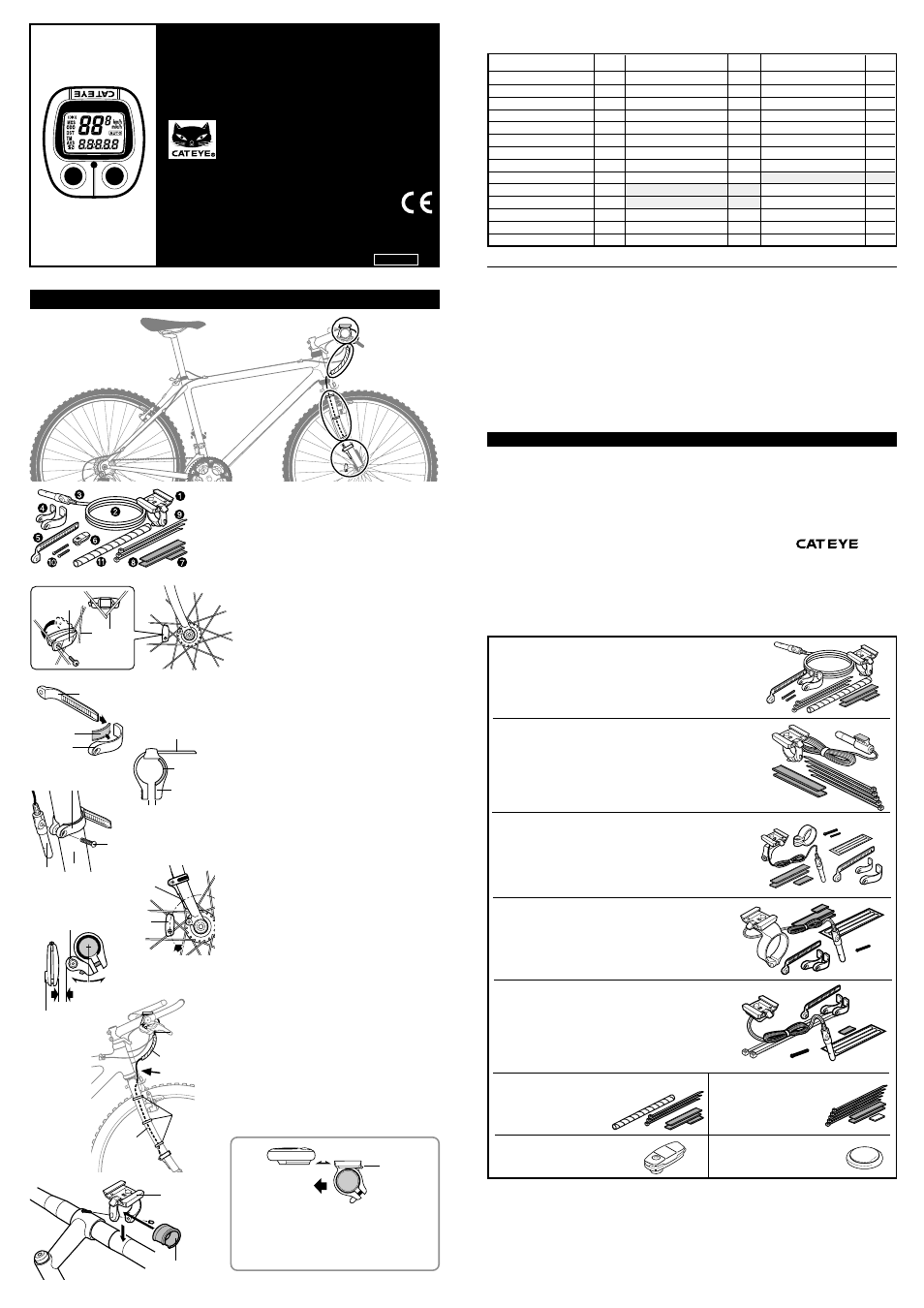

MOUNTING TO BIKE

Fig.9

lever

#169-9731

Heavy Duty Wire and Bracket Sensor Kit

#169-9771

Bracket Sensor Kit for Extra Large Fork

#169-6168

Bracket Sensor Kit for Aero Bar

#169-6167

Center Mount Bracket Kit

#169-6169

Stem Mount Bracket Kit

#169-9750

#169-9751

Attachment Kit (For Heavy Duty Wire)

Attachment Kit (For TOMO XC)

#166-5120

#169-6180

Wheel Magnet

Lithium Battery(CR1620)

SPECIFICATIONS

Controller ----------------------------------- 4-bit 1-chip Microcomputer (Crystal Controlled Oscillator)

Display -------------------------------------- Liquid Crystal Display

Sensor -------------------------------------- No Contact Magnetic Sensor

Operating Temperature Range ------- 0

°

C - 40

°

C (32

°

F - 104

°

F)

Applicable Cycle Sizes ------------------ 130cm - 229cm

The length of the wire ------------------- 70cm

Applicable Fork Diameter -------------- 11ш - 40ш (S:11 - 26ø L:21 - 40ø)

Power Supply ----------------------------- Lithium Battery (CR1620 or CR1616) x 1

Battery Life --------------------------------- Approx. 3 years(The life of the first factory-loaded battery may

be shorter than this period.)

Dimension/Weight ------------------------ 1-15/16" x 1-25/32" x 5/8" (49 x 45 x 16 mm) / 0.74 oz (21 g)

* The specifications and design are subject to change without notice.

LIMITED WARRANTY

1-Year Warranty for Main Unit Only

(Accessories/Attachments and Battery Consumption excluded)

If trouble occurs during normal use, the part of the Main Unit will be repaired or replaced free of

charge. The service must be performed by Cat Eye Co., Ltd. To return the product, pack it carefully

and remember to enclose the warranty certificate with instruction for repair. Please write or type your

name and address clearly on the warranty certificate. Insurance, handling and transportation charges

to our service shall be borne by person desiring service.

(Address for service)

2-8-25, Kuwazu, Higashi Sumiyoshi-ku, Osaka 546-0041 Japan

Attn.: CAT EYE Customer Service Section

Service & Research Address for United States Consumers:

CAT EYE Service & Research Center

1705 14th St. 115 Boulder, CO 80302

Phone : 303-443-4595

Toll Free: 800-5CATEYE

Fax

: 303-473-0006

e-mail: [email protected]

CO.,LTD.

E

Slide the main unit onto the bracket from

front until it clicks into position. To remove

it, pull it off forward while pushing down the

lever. (Fig.9)

• The spokes must run correctly through the

inside the magnet as in fig.1.

• Attach the sensor with Sensor Bands-A-B to

the right fork. Choose a band that fits the fork

diameter (S size for up to 24ø, L for

oversize). If the front fork is thick, use the

longer screw.

1. Insert the band-B into the slit of the band-

A, and put the rubber pad inside of the

band-A(fig. 2). Adjust the length in order

that the screw-fastening part of the bands

are parallel when mounted to the fork(fig.

3). *To pull out the band B from band A,

tug strongly.

2. Mount the adjusted bands to the fork along

with the sensor, by temporarily tightening

the screw(fig. 4).

3. Align the magnet's center and the sensor's

marking line(fig. 5), and make sure of

2mm clearance between the magnet and

sensor (fig. 6). Then tighten the screw

securely. Cut the excess of the band-B

with a nipper or the like.

• Secure the wire with nylon ties as shown in

fig. 7. Wind the wire round the outer cable

and wrap these wires with the spiral tube.

Adjust the length of the wire. Loosen the wire

in the area marked with the arrow so that the

wire does not hinder handlebar operation.

• Use either 1mm- or 2 mm-thick pads if

necessary, according to handlebar diameter.

Attach the bracket close to the handlebar

stem (fig. 8).

• Slide main unit onto the bracket from front

until it clicks into position. To remove, pull it

off forward while pushing down the lever. (fig.

9)

•Test

Mount main unit. If main display does not show

any figures, press either M button or S/S button

to release from power saving function. Spin the

wheel to check if sensor pulse symbol flashes.

If not, adjust relative positions of magnet and

sensor following the instructions.

TIRE SIZE

L(cm)

TIRE SIZE

L(cm)

TIRE SIZE

L(cm)

20 x 1.75

150

26 x 1.40

200

650 x 38B

211

24 x 1

175

26 x 1.50

199

700 x 18C

207

24 x 3/4 Tubular

178

26 x 1.75

202

700 x 19C

209

24 x 1-1/8 Tubular

179

26 x 1.95

205

700 x 20C

209

24 x 1-1/4

191

26 x 2.00

206

700 x 23C

210

24 x 1.75

189

26 x 2.1

207

700 x 25C

211

24 x 2.00

192

26 x 2.125

207

700 x 28C

214

24 x 2.125

196

26 x 2.35

208

700 x 30C

217

26 x 1(559mm)

191

27 x 1

215

700 x 32C

216

26 x 1(650c)

195

27 x 1-1/8

216

700C Tubular

213

26 x 1.25

195

27 x 1-1/4

216

700 x 35C

217

26 x 1-1/8 Tubular

197

27 x 1-3/8

217

700 x 38C

218

26 x 1-3/8

207

650 x 35A

209

700 x 44C

222

26 x 1-1/2

210

650 x 38A

212

nyron ties

Fig.7

outer cable

wire

spiral tube

Fig.5

markingline

of sensor

center of

magnet

sensor band B

sensor

band A

Fig.3

rubber pad

sensor band B

Fig.4

sensor band A

Fig.2

screw

magnet

sensor

Fig.6

rubber pad

parallel

sensor

about 2mm

fork

sensor band A

1. Bracket

2. Wire

3. Sensor

4. Sensor Bands-A (S)(L)

5. Sensor Bands-B

6. Magnet

7. Sensor Band Rubber Pad

8. Bracket Rubber Pad (2 pcs.)

9. Nylon Tie (3 pcs.)

10. Sensor Band Screw (S)(L)

11. Spiral Tube