Great Planes U-Can-Do 3D 46 ARF - GPMA1269 User Manual

Page 19

❏

7. Thread a clevis 25 turns onto one end of each of the three

12" [305mm] pushrods. Slip a silicone retainer over the clevises.

❏

8. Make three one-arm servo arms. Enlarge the holes in

the arm with a Hobbico Servo Horn Drill (or a #48 or 5/64"

(2mm) drill bit) so the pushrod will fit.

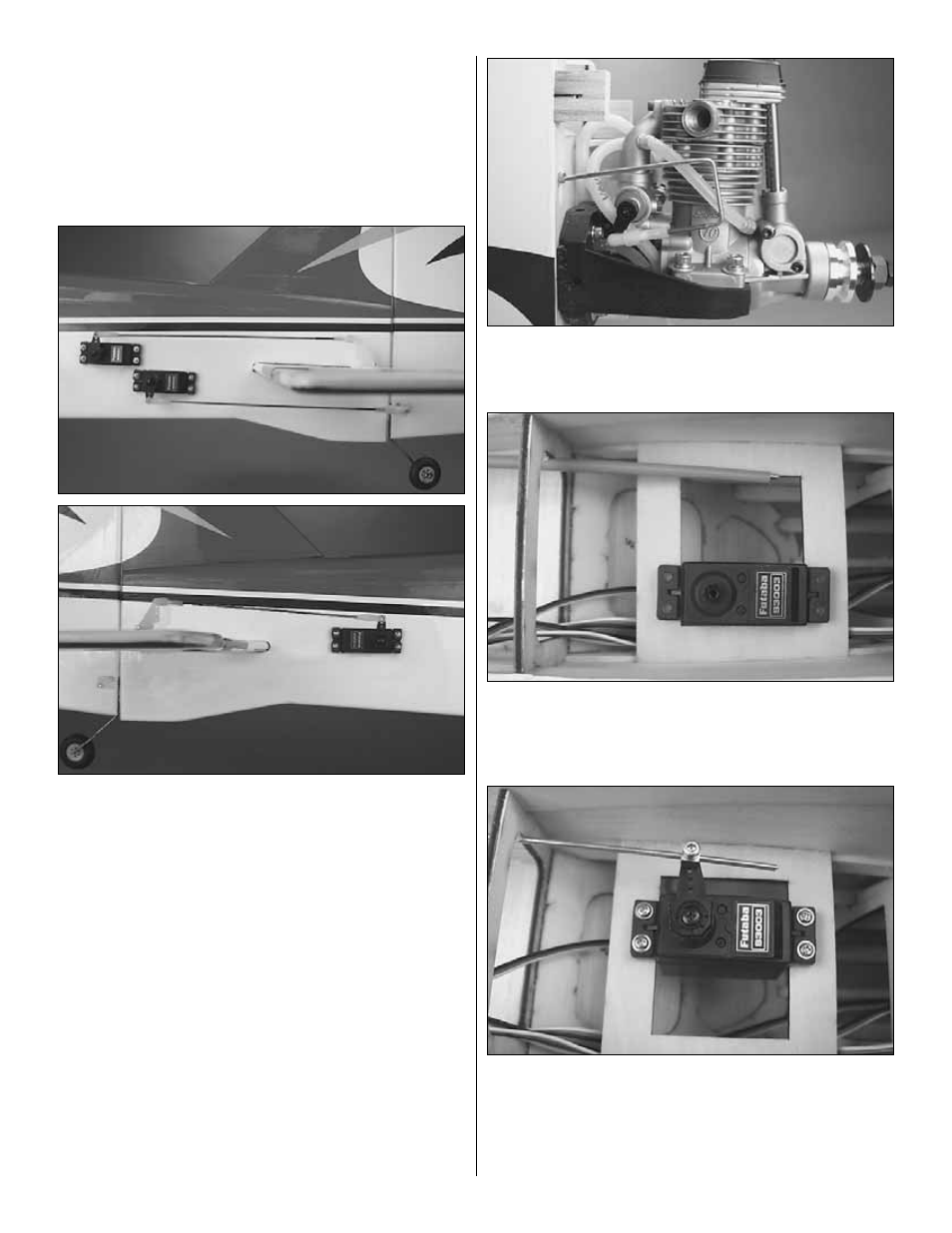

Use these photos for the next three steps.

❏

9. Connect the servo leads to the receiver. Turn on the

transmitter and receiver to center the servos. Attach the

servo arms to the servos 90 degrees to the servo.

❏

10.Attach the clevises with pushrods to the control horns.

Hold the control surfaces straight and mark the pushrods

where they cross the servo arms. Bend the pushrods 90

degrees away from the fuse on the marks you made. Turn

the receiver and transmitter off.

❏

11. Using Faslinks, attach the pushrods to the control

horns. Trim the pushrod, being certain to leave 1/16"

[1.6mm] of wire protruding from the Faslinks.

❏

12. Screw a clevis 10 turns onto the end of the 17-1/2"

[445mm] throttle pushrod. Bend the pushrod as necessary

for a smooth action.

❏

13. Glue the servo tray in place with medium CA, as

shown in the photo. Fit the throttle servo in the tray but do

not screw it in place at this time.

❏

14. Connect the throttle pushrod to the throttle servo with

the screw-lock connector.

❏

15. Let the pushrod locate the servo in the tray. Mount

the servo to the servo tray with the hardware provided with

your servo.

19