Assemble the fuel tank – Great Planes Easy Sport 40 ARF - GPMA1035 User Manual

Page 9

fit of the outer pushrod tubes to the pushrod exits. If the fit

is too tight, trim the opening slightly with a hobby knife to

allow the pushrod to fit without binding.

❏

3. Roughen the outside of the outer pushrod tubes

using 220-grit sandpaper.

❏

4. Insert the 36" threaded wire rods through the

pushrod tube openings into the fuselage from the rear and

guide them through former #4. Do not allow the pushrods to

cross each other inside the fuselage. If the pushrods are

crossed during the installation, the nose gear will operate in

the opposite direction of the rudder, making ground handling

of the aircraft rather difficult. Slide the outer pushrod tubes

into place from the inside using the threaded rods as guides.

Leave approximately 1" of the outer pushrod tube in front of

former #4. Apply thick CA to the points where the outer tubes

contact former #4 and at the exits.

❏

5. Trim one of the remaining pushrod tubes to 12". After

roughening the tube with 220-grit sand paper, install the

tube into the upper right hole in the firewall. This will be

used for the throttle pushrod. Leave about 1/4" of the tube

exposed in front of the firewall. Glue the pushrod tube to

both sides of the firewall using medium CA.

❏

6. Trim the other remaining outer pushrod to 13-1/2" for

use as the nose wheel pushrod tube. After roughening the

tube with 220-grit sand paper, install the tube into the lower

left hole in the firewall. This tube should be installed flush

with the front of the firewall. Glue the pushrod tube in place

from the back of the firewall using medium CA.

❏

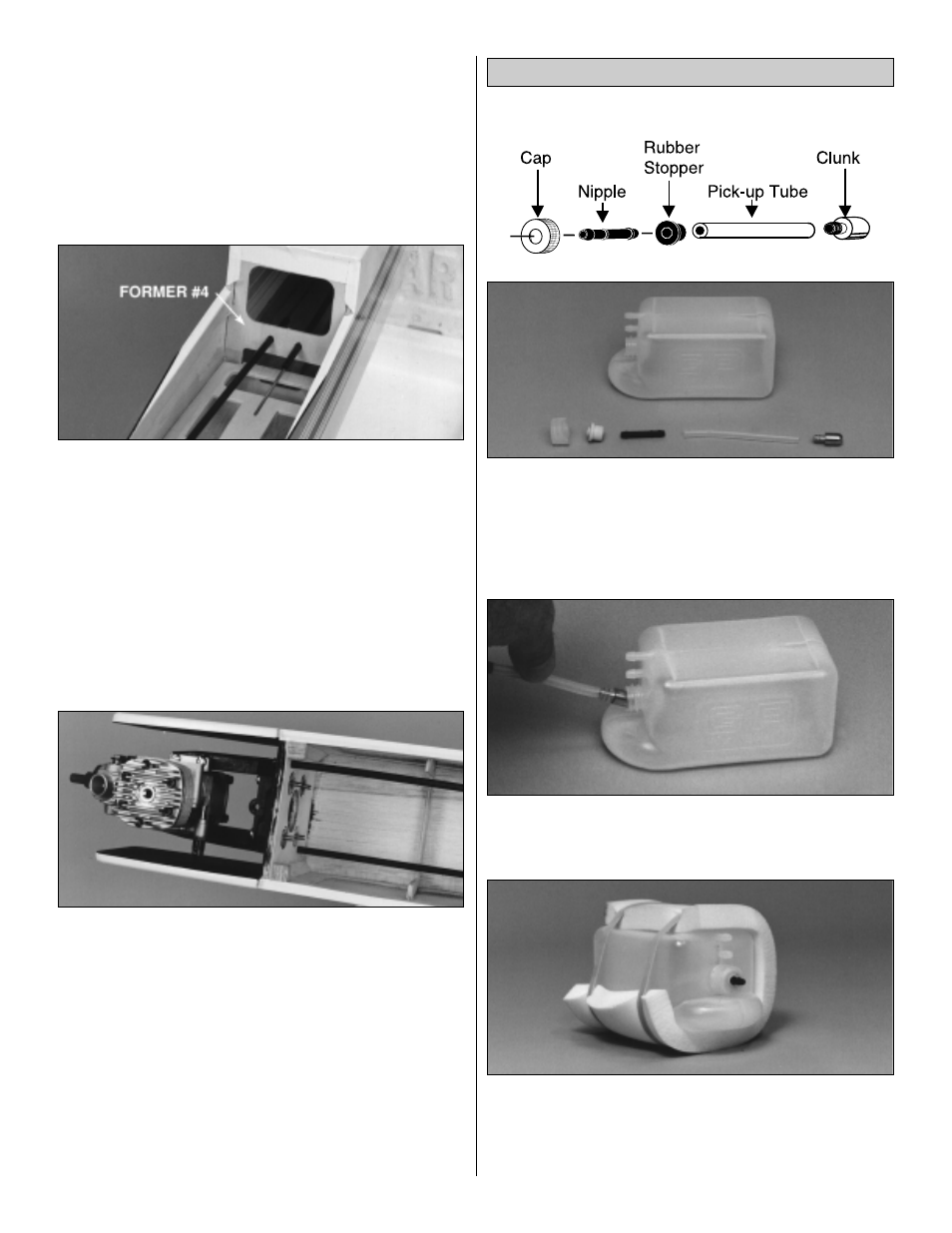

1. Push the straight nipple through the rubber

stopper until the ridge (1/4" from one end) contacts the

outside face of the stopper. Cut the pick-up tube to 2-7/8".

Push one end of the pick-up tube all the way onto the

clunk and the other end all the way onto the nipple.

❏

2. Insert the pick-up tube assembly into the tank, then

thread the cap over the stopper, tightening it securely.

❏

3. Wrap the 3-1/2" x 7-7/8" x 1/2" sheet of foam rubber

around the tank as shown in the photo. Secure it into

position with a couple of rubber bands. The reason for the

open area on the side of the tank is to allow clearance for

the throttle pushrod tube.

Assemble the Fuel Tank

9