Great Planes BL-8 Brushless ESC - GPMM2070 User Manual

Page 4

armed and ready for operation. Skip to Step 8 if you do not

wish to make any other programming changes. To CHANGE

ANOTHER programmable feature disconnect the battery from

the ESC and return to Step B above.

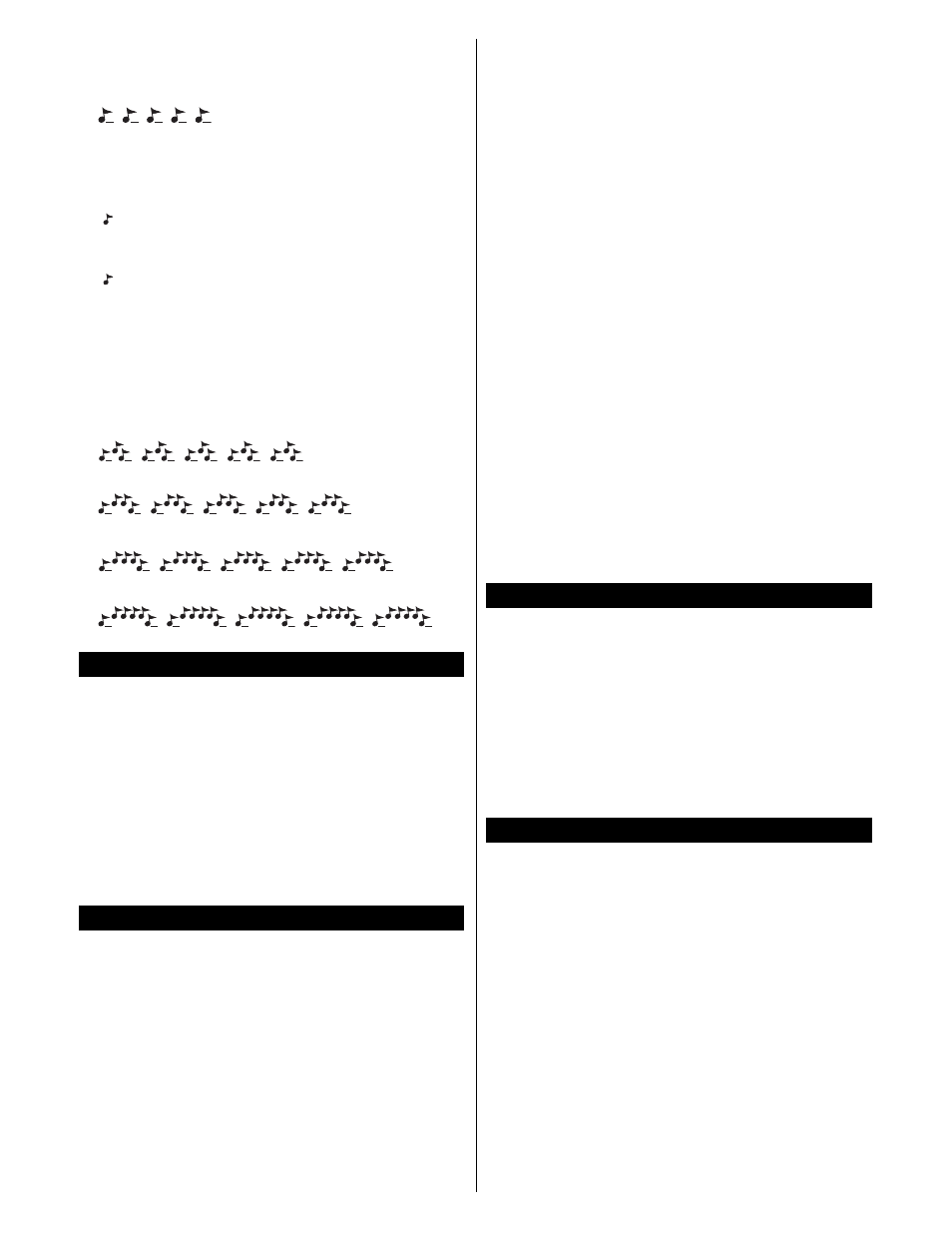

L. ACTIVE RPM CONTROL: The ESC will sound four different

series of tones to indicate the four RPM control options as

shown below. To CHANGE the RPM control setting, move the

throttle stick to minimum when you hear the tones that match

the setting you wish to have. The ESC will sound a single tone

“

” to indicate the new setting was accepted. The ESC will

now be armed and ready for operation, and skip to Step 8. If

you do NOT wish to change the RPM setting do not move the

throttle stick, and after the last tones sound the ESC will sound

“

” to indicate the programming mode has finished, the ESC

is now armed, and go to Step 8.

The active RPM control function is designed for use with small

electric helicopters. Selecting the proper RPM maximum

control value will help to prevent the ESC from overpowering

the model during flight. Refer to your helicopter’s instruction

manual for a recommended maximum RPM value. Leave this

setting “OFF” for model airplanes.

RPM control off (factory default):

first range (20,000 RPM max.):

second range (50,000 RPM max.):

third range (100,000 RPM max.):

Once all connections have been made and all programming has

been set it’s a good idea to perform a range test with your radio

before attempting a flight to ensure that a good Rf link exists

between the transmitter and the airplane. With the Tx antenna

collapsed and a helper holding the airplane, apply full throttle and

operate the other flight controls while walking away from the

airplane. Full control should be maintained at a range of up to

approximately 75 to 100 feet away from the airplane. If the system

fails this range test it may be necessary to re-route the location of

the Rx and/or its antenna away from linkages or electronic

components in the airplane. Refer to the radio’s instruction

manual for further details.

ESC DOES NOT WORK

Problem: Motor and/or Rx or servos do not function.

1. Batteries are dead. Recharge batteries.

2. Check for incorrect or faulty battery connections.

3. Check for a damaged connection between ESC and Rx.

4. Check for faulty motor connections.

5. Internal damage. Unit may require service. See

“Service

Procedures.”

6. Make sure the ON/OFF switch is set to “ON.”

Problem: Motor rotates in the wrong direction.

1. Motor wires attached incorrectly. See

“Step 4 – Motor

Connection.”

2. “Reverse rotation” setting in ESC must be changed. See

“Step 5 – Speed Control Setup.”

ESC WORKS BUT OTHER PROBLEMS EXIST

Problem: Rx glitches or stutters during acceleration.

1. Rx mounted too close to ESC causing interference. Relocate

Rx away from ESC.

2. Check for faulty power connections.

Problem: Rx and servos function, but programming tones do not

function properly (does not emit setup tones).

1. ESC may need to be reset. Remove and re-apply power to the ESC.

2. Check the Tx throttle channel to see if it needs to be reversed.

3. Check ATV, EPA or ATL must be set to maximum or +/- 100%.

Problem: Model runs slowly or has no acceleration.

1. The ESC is not set up properly. Repeat

“Step 5 – Speed

Control Setup.”

2. Check for faulty battery and/or motor connections.

3. Tx is improperly adjusted. Repeat

“Step 4 – Transmitter

Adjustments.”

Problem: Rx and servos function, but motor does not rotate.

1. Tx is improperly adjusted. Repeat

“Step 4 – Transmitter

Adjustments.”

2. Check for faulty motor connections.

3. Motor is bad or hung up. Clean or replace motor.

Problem: Motor seems to function very inefficiently, has difficulty

in starting to rotate, or hesitates when trying to rotate.

1. The timing feature is set improperly for the selected motor. See

“Step 5 – Speed Control Setup.”

2. Check for faulty motor connection.

3. Problem with motor. Try a different motor.

Problem: Low voltage cutoff indicator activates at improper voltage.

1. Low voltage cutoff feature set improperly. See

“Step 5 –

Speed Control Setup.”

2. Bad cell or battery pack. Replace battery.

ESCs that operate normally when received will be charged a

minimum service fee and return shipping charges. Before sending

your ESC in for service, it is important that you review the

“Troubleshooting Guide” in this instruction sheet. The ESC may

appear to have failed when other problems exist in the system,

such as a defective Tx, Rx or servo, or incorrect

adjustments/installation.

•

Hobby dealers are not authorized to replace ESCs thought to

be defective.

•

Do not cut the input harness, switch harness, or power wires

of the ESC before sending it for service. A fee will be charged

for cut wires which must be replaced for testing.

Great Planes

®

warrants this product to be free from defects in materials and

workmanship for a period of 180 days from the date of purchase. During that

period, Great Planes will, at its option, repair or replace without service charge

any product deemed defective due to those causes. You will be required to

provide proof of purchase (invoice or receipt). This warranty does not cover

damage caused by abuse, misuse, alteration or accident. If there is damage

stemming from these causes within the stated warranty period, Great Planes

will, at its option, repair or replace it for a service charge not greater than 50%

of its then current retail list price. Be sure to include your daytime telephone

number in case we need to contact you about your repair. This warranty gives

you specific rights.You may also have other rights, which vary from state to state.

For service on your Great Planes product, warranty or non-warranty, send it

post-paid and insured to:

HOBBY SERVICES

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

(217) 398-0007

e-mail:

*For warranty and service information if purchased outside the USA or Canada,

see the additional warranty information insert (if applicable) or ask your retailer

for more information.

www.greatplanes.com

www.electrifly.com

180 DAY LIMITED WARRANTY – *U.S.A. AND CANADA ONLY

SERVICE PROCEDURES

TROUBLESHOOTING GUIDE

STEP 8 – RANGE TEST

GPMZ0307 for GPMM2070

Made in China Entire Contents © Copyright 2005