Cutter - drive belt collector - drive belts – Countax A50 User Manual

Page 13

Page 16

Page 13

Cutter - Drive Belt

Collector - Drive Belts

Before carrying out tests or adjustments

(the problem may be simpler) – first

CHECK the following points:

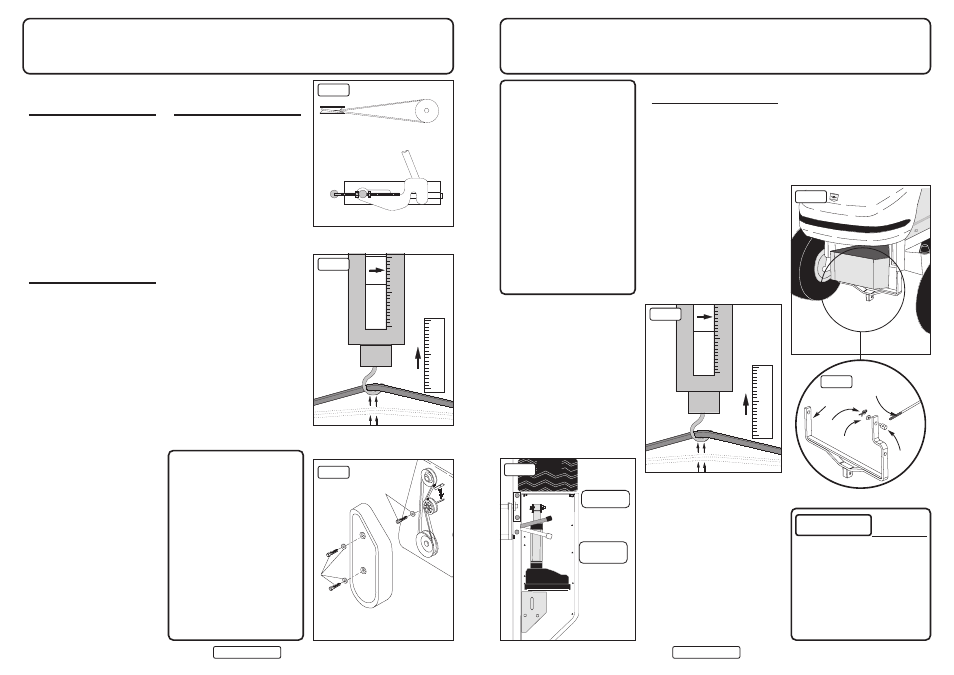

1. Is the Engine to Cutter Drive Belt

slipping? Check that the Drive Belt

Tension Lever (fig 1) under the left

running board is in the rear (tensioned)

position. If not, rectify – this is the

most likely cause.

2. Has debris collected in the Cutter Deck

Pulley Housing (Page 9)? If so remove

the cover and remove the

obstruction.

ENGINE TO CUTTER DRIVE

BELT TENSION

The correct tension of the Cutter Drive

Belt (Engine to Deck) is critical. If

incorrectly set it can lead to engine

damage.

To check the tension, follow this

procedure:

1. Put the Deck in a middle cutting height

position (5 on the decal).

2. Select the midway position on the Belt

between the front (Electric Clutch)

pulley and rear (Cutter Deck) pulley

and using, a spring balance; apply a

2Kg (4 to 5lbs) pull (fig 2).

3. Using a ruler or tape, measure the

deflection achieved which must be

13mm (1/2"). If more the belt tension

must be increased, if less decreased.

To correct the tension, follow this

procedure:

1. Release the tension on the belt by

pulling the Belt Tension Lever forward

(see fig 1).

2. Taking care not to burn yourself on a

hot exhaust, locate the Trunnion at the

end of the Belt Tension Rod – lift the

bonnet and look to the front (nearside)

close to the exhaust (see fig 3).

3. Remove the spring clip and washer

holding the Trunnion in place on the

Deck Tension Cradle (fig 3a) and

release the Trunnion so it can be

turned.

4. Both the Trunnion and the Belt Tension

Specified Belts and Blades

Engine/Deck Belt - B57 Dayco Super II -

Pt No. 22940100

Deck Internal Drive (Mulcher) - BB112

Pt No. 228000900

(Rear Discharge) - Dayco Super II BB155

Pt No. 22950200

Mulcher Blades x3 Pt No. - 16938100

IBS RH Blade Pt No. 169381300

IBS LH Blade Pt No. 169381400

IBS Front Blade Pt No. 1692000

PGC A49 Drive Belt Pt No. 22923400

PTO Drive Belt - Dayco Super II A92 -

Pt No. 22950100

Transmission Drive Belts - A91 Dayco

Super II - Pt No. 228001500

N.B. Only use specified Belts and Blades

- Never accept a substitute!

Rod are threaded. You increase Belt

tension by winding the Trunnion

towards the end of the Rod and reduce

tension by winding in the reverse

direction.

5. Having made the adjustment re-locate

and secure the Trunnion, re-tension the

Belt with the Belt Tensioner Lever –

then re-check the Belt tension.

ON NO ACCOUNT MUST THE

TRACTOR BE RUN WITH THE

ENGINE TO CUTTER DRIVE BELT

OVER-TENSIONED AS IT WILL

DAMAGE THE ENGINE. As any such

damage will NOT be covered by

warranty you may prefer that your

dealer sets the tension.

Kg

cm

fig 1

fig 2

fig 3

View from underside

Trunnion

Deck Tension

Washer

Cradle

Spring Clip

Deck Tension Rod

WARNING

REPLACING AND

TENSIONING PTO DRIVE

BELT CONNECTION

It is important that the belt from PTO to

collector (Part No. 22923400) is crossed

over in the correct direction (fig 1) before

being fitted over the collector pulley. The

easiest way to do this is to place the belt

on the PTO pulley and then stand behind

the Tractor holding the belt with two

hands. Turn the right hand above the left

and fit the belt on to the collector pulley.

To check that you have this right - start

your Tractor and engage the PTO lever

and check that the brush is revolving

against the forward direction of the

Tractor (see page 15 fig 1).

CORRECT BELT TENSION

To check tension:

1. Lower the collector to the operating

position and check the tension using a

spring balance and a ruler.

2. Select a place on the belt midway

between the PTO pulley and the

collector pulley.

3. Pull and measure the deflection using a

ruler (fig 2). It should be 19mm at 2kgs

(4-5lbs).

If the tension needs to be adjusted - first:

1. Relocate the Collector from the

Tractor.

2. Locate the adjustment holes on the

Locking Arms. These holes take the

nuts and bolts on which the Locking

Arm hinges.

3. To increase tension on the belt undo

each nut and bolt and relocate them

one or more holes forward (towards

the Tractor). To slacken move the bolts

back. Ideally the bolts should be in the

same hole on each Locking Arm,

however fine adjustment to get the

right tension may only permit you to

move one bolt - this is OK but there

should not be more than one hole

difference from side to side.

4. Replace the Collector on the Tractor

and re-check the belt tension.

CHECKING, TENSIONING

AND REPLACING SIDE

DRIVE BELT (fig 3)

1. First remove Collector from the

Tractor (page 14).

2. To remove the plastic cover, remove

the two nuts and bolts (A) using a 1/2”

spanner and socket.

3. Using a 1/2” spanner and socket,

slacken the nut and bolt (B) holding

the tension pulley and slide the pulley

out of the way.

4. Remove the belt and fit the Countax

replacement (Dayco Super II A38 Part

No. 22950300)

5. Tension the belt by sliding back and

securing the belt tensioner. The tension

is not critical but the belt must not be

too tight. The ideal is 13mm (1/2”)

deflection at 2Kgs (4/5lbs) pull -

use a spring balance and ruler or tape

to check.

6. Make sure that the rectangular cover

plate fits over the adjustment slot -

failure to do this will allow cuttings

and grit to accumulate and damage the

pulleys and belt assembly.

7.Replace the plastic cover.

Kg

cm

A

B

PLEASE NOTE:

The information contained in

the following pages is given

on the understanding that

Countax accepts no

responsibility for work

carried out by a customer or

for any damage thus caused,

whether or not the service

instructions have been

misunderstood. To be

absolutely sure that your

warranty terms are not

breached, service work

should only be carried out by

a Countax dealer.

fig 3a

19mm deflection 2kgs push or pull

To Tighten

To Slacken

fig 1

fig 2

fig 3

Cutter Belt

De-Tensioned

Cutter Belt

Tensioned