Mc850c i, Nstruction, Anual – Futaba MC850C User Manual

Page 2: Connection led display, Set up

N

N

N

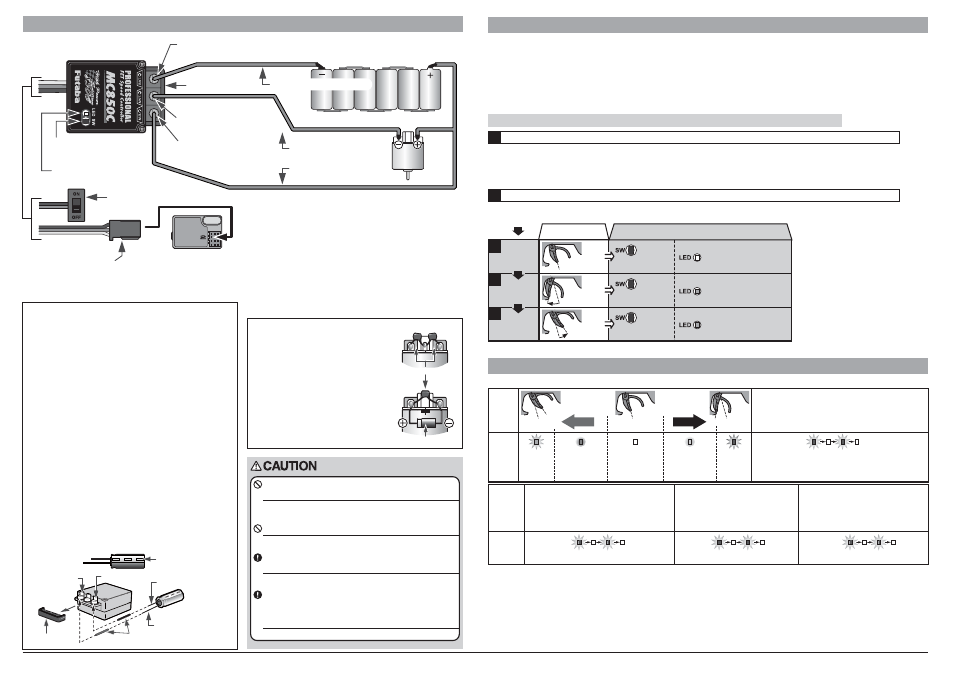

CONNECTION

LED DISPLAY

Negative (-M) motor

Positive (+B) battery

(+M) motor

Receiver connector

Connects to the receiver

throttle channel (CH2).

Power switch

Pushbutton switch

LED

Terminal cover

Negative (-B) battery

Negative terminal mark

POWER CAPACITORS

Power Capacitor stores battery energy and supplies this

to the motor additionally when extra power is required.

[Reference]

The MC850C has excellent acceleration and throttle

follow-up, but use this power capacitor when the course

to be run requires more than maximum power. However,

on a small technical course, not using the power

capacitor may also be effective.

[INSTALLATION]

See the pictures for the example of installation.

1

Remove the terminal cover from the MC850C.

2

Use the included heat shrink tube to isolate the pins of the

Power Capacitor. This will also make it easier to indicate the

polarity of the Power Capacitor. Place the red heat shrink tube

on the positive terminal and the black heat shrink tube on the

negative terminal.

3

The Power Capacitor needs to be soldered to the speed control

between + (positive = M.B.+ ) and - (negative = BAT.-).

4

Attach the terminal cover to the MC850C.

[Wiring Precautions]

• Always set the MC850C power switch to the OFF position before

performing any wiring.

• When stripping the covering of the silicon cord to the length

needed for soldering, be sure not to cut the center conductor with

the cutter or nippers.

• Refer to the diagram above and check the polarity before

performing wiring. (The 3 colors, red, blue, and black, of the

silicon cord indicate the polarity.)

• When soldering to the terminals of the MC850C, remove the

terminal cover. (After soldering, re-install the terminal cover.)

Heat shrink tube

(positive = red / negative = black)

Never reverse the capacitor,schottky diode and wires

polarity.

The capacitor may break or the capacitor electrolyte may leak.

The schottky diode breaks.

Reverse connection will immediately destroy the amp.

Never use solder containing acid flux.

Use solder containing rosin flux only. Do not inhale the solder

vapours. This might damage health.

Vibrationproof the capacitor by mounting it with thick

double sided tape.

If the pin of the capacitor is broken, it may short-circuit with the pin

between + and - terminal of the speed control.

Be careful when soldering to the tags on the speed control;

don’t overheat the tags with your soldering iron and take

great care to avoid short-circuits between two of the three

tags on the speed control.

Such a short-circuit would destroy the speed control.

Silicone flex wire Red

Silicone flex wire Blue

Silicone flex wireBlack

In set-up mode MC850C stores every step when you press the Set-up button. All the settings are stored in the unit even when the

speed control is subsequently disconnected from the battery. Set up the following basic functions on your transmitter (if present):

• High ATV, EPA (throttle travel) - maximum Low ATV, EPA, ATL (brake travel) - maximum

• EXP, EXPO (exponential) - start with 0

• SUB trim (neutral trim) - center TH trim - center

• Throttle reverse (servo reverse) - any setting; must not be changed after completion of set-up procedure.

• Asymmetrical stick travel is possible (2/3 throttle - 1/3 brake)

If your transmitter does not feature these set-up functions, it is already in “basic set-up” mode.

Remove the motor pinion, or ensure in some other way that the wheels of the model are free to rotate.

• Switch the transmitter on.

• Set the transmitter throttle stick to neutral, and then switch the speed control on.

• Depending on the neutral position of the throttle stick, the red and green LED will blink simultaneously (orange) and a beeping

sound will be repeated. (Alarm: Waiting for neutral data)

Turn on the power in following order.

• The SET LED flashes green, to indicate that the unit is in set-up mode.

• This completes the set-up procedure.

Hold the SET button pressed in for at least 3 seconds using the small screwdriver supplied.

Motors with no suppressor capacitors, or

inadequate suppression, may cause the MC850C

to malfunction. Always solder the capacitors

supplied to your motor.

The schottky diode improves the efficiency of

the speed control / motor combination and

provides extra protection to the brake FETs. The

white ring must always face the positive side.

Schottky diode

Suppressor capacitors

Solder the suppressor capacitors and the

Schottky diode to the motor.

©FUTABA CORPORATION

2007,02

MC850C

Protection Circuits

Heat protection: After FET overheating is detected, the output to the motor is gradually lowered and when 125 degress is reached, a

protection circuit operation alarm is activated and output to the motor is cut. The protection circuit is automatically reset by a drop in

the FET temperature.

Low battery protection: When the power supply voltage drops, the output current to the motor is limited and supply voltage to the

receiver is ensured. When the power supply voltage drops to the set voltage (initial setting 3.0V), a protection circuit operation alarm is

activated and output to the motor is cut. The protection circuit is automatically reset by recovery of the power supply voltage.

MC850C

I

NSTRUCTION

M

ANUAL

Terminal

cover

SET button operation

LED

Neutral

point

setting

High

point

setting

Brake MAX

point

setting

• Neutral state

The MC850C operating state can be checked with the LED as shown below.

flashes red and the motor beeps.

*Not used with PCM receivers.

*When the transmitter if OFF, this function is not performed

in environments such that the servo operates erroneously

Off

On (green)

On (red)

Neutral

point

High

point

Brake MAX

point

Brake

Foward

On (red)

*Becomes

brighter nearer

the MAX point.

On (green)

*Becomes

brighter nearer

the high point.

LED

LED

* The confirmation beep sounds only when the motor was connected.

(-;negative)

(+;positive)

(-;negative)

(+;positive)

SET UP

• Full brake

state

• Full high

state

• Press SET button

once.

• Press SET button

once.

• Press SET button

once.

LED goes out

and the

motor beeps.

flashes green two times

and the motor beeps.

LED goes out

flashes orange and the motor beeps.

flashes orange and the motor beeps.

flashes red and the motor beeps.

flashes green three times

and the motor beeps.

LED goes out

* Since the data is read at the end of setting

of all points, the points cannot be set

independently.

* If the amp power was turned off during

setting, the setting points cannot be

memorized. (The previous settings are

retained.)

* The confirmation beep sounds only when

the motor was connected.

* If you make a mistake during the set-up

procedure, an setting is not completed.:

switch MC850C off and start again from

the first step.

* Check the operation by the following "LED

DISPLAY." When throttle operation and

the CHECKER LED DISPLAY are not

correct, set up again from the first step.

(Amp power left on alarm)

When the transmitter power

was turned off first.

*at Neutral Brake:

On (green or red)

*When the switch of speed control is turned ON

ahead of a transmitter.

*When the neutral position of a transmitter

differs from the last setup.

(Alarm when waiting for the data of a

neutral point)

Operation

Cause

(Protection circuit operation)

When a protection circuit operates.

(Data error alarm)

Displayed when an abnormal

signal was input.

Transmitter throttle

operation

3

4

5

1

2

FUTABA CORPORATION Makuhari Techno Garden Bldg., B6F 1-3 Nakase, Mihama-ku, Chiba 261-8555, Japan Phone: (043) 296-5119 Facsimile: (043) 296-5124