Utput, Able, Onnection – Flintec KPB-4 User Manual

Page 4: Orner, Orrection at, Cales with, Lintec, Ells

Junction Box Type KPB-4 – Technical Manual, Rev. 1.00 September 2007

Page 4 of 4

O

UTPUT

C

ABLE

C

ONNECTION

The signal cable (connection between junction box and the following electronics) should be a 6 – wire

shielded cable and has to be kept as short as possible. It will be pulled through a cable inlet which has to be

prepared at site.

Then feed the tin-plated wires through the hole at the solder point. Use a suitable soldering iron for electronic

works (at least 30 Watt ). Proper solder joints always look bright and shiny.

Never use soldering solution and soldering grease! This will destroy the printed circuit board!

Always use suitable electronic solder, e.g. S-Sn60Pb40 DIN EN 29453.

Depending on type and manufacturer signal cables may have different colours. Therefore make your own

choice.

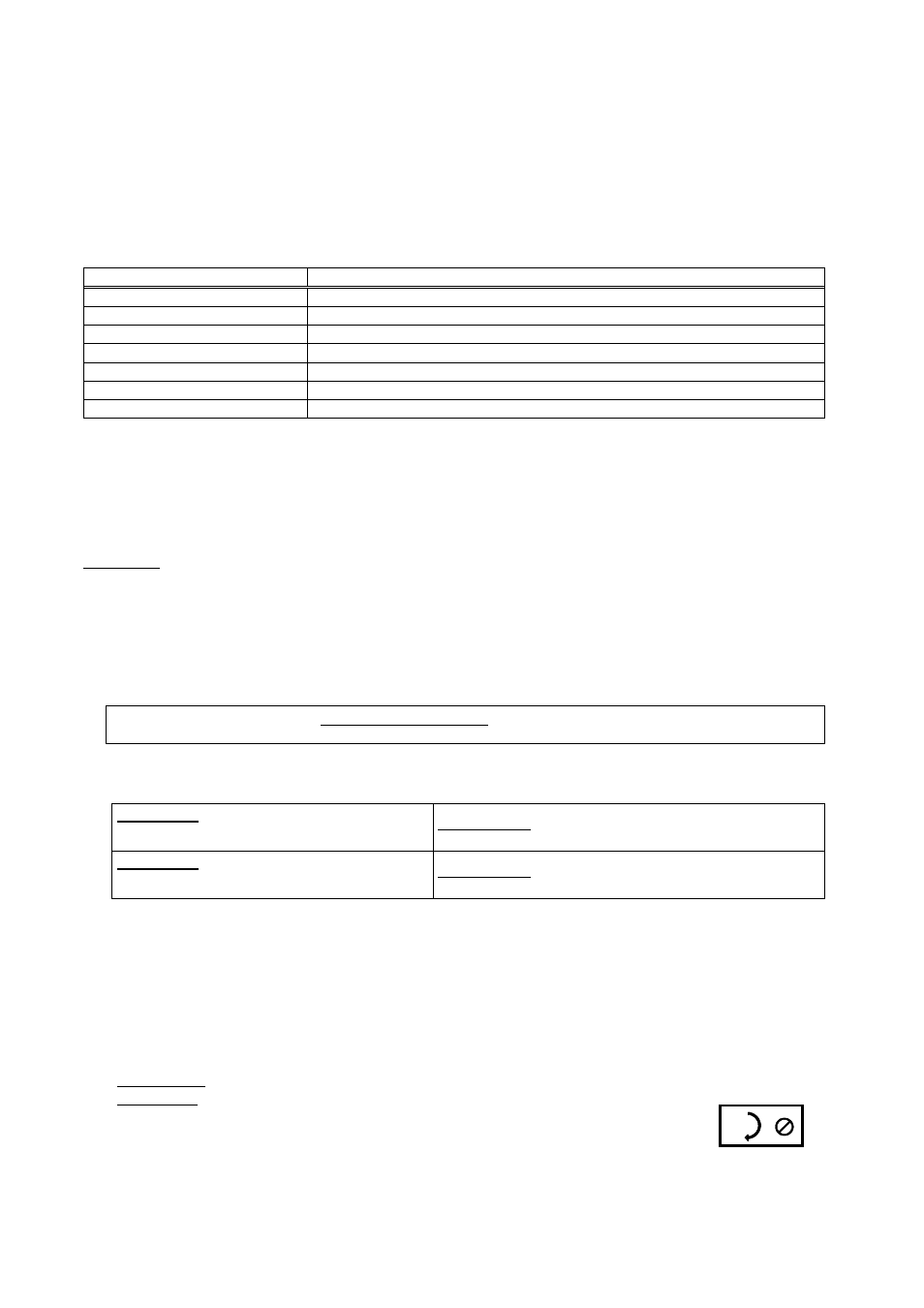

Cable colour, example

Description / Terminal designation

outer cable screen

= Shield

pink

= Out – (Signal –)

white

= Out + (Signal +)

grey

= Sense –

brown

= In – (Excitation –)

yellow

= Sense +

green

= In + (Excitation +)

C

ORNER

C

ORRECTION AT

S

CALES WITH

F

LINTEC

L

OAD

C

ELLS

Flintec load cells are manufactured with rather tight tolerances, so in most cases an additional corner

correction is not required. The best conditions are achieved if you use load cells of the same class

(Designation is done with capital letters A to I on the load cell package besides the type label).

Hint: Corner errors can have a mechanical background, e.g. sloped mounting surface of the load cell.

Procedure:

1. The jumpers JP1 to JP4 besides the potentiometer should stay installed. This will disable the

potentiometers (shipment status).

2. Get the display value for each corner. Use the highest possible display resolution (e.g. factor 10 or higher)

or, if this is not possible, measure the the digital weight increment using corresponding weights.

3. The corner with the lowest display value is the starting point for the corner correction. The differences of

the other corners are calculated with reference to this “basic corner”.

4. Calculate the correction resistance as follows:

Deviation in [kg]

Correction resistance [Ω] =

Test load in [kg]

X Input resistance of the load cell [Ω] *

* 1100 Ω input resistance for:

BK2, SB4, SB5, SB6, SB14, SLB, ZLB, UB1, UB5, UB6, PB, RC3

400 Ω input resistance for:

RC1, SB2

Example 1: 1100 Ω load cell

0.1 kg corner error with 500 kg test load

0.1 kg

500 kg

x 1100 Ω

Ω

Ω

Ω =

0.22 Ω

Example 2: 400 Ω load cell

10 kg corner error with 5000 kg test load

10 kg

5000 kg

x 400 Ω

Ω

Ω

Ω =

0.8 Ω

5. The calculated correction resistance is used as the starting point when the correction is made with the

potentiometers P1 to P4 (25 turns; version 1: 10 Ohm Cermet- precision trimmer; version 2: 50 Ohm

trimmer). When shipped all potentiometers are in the middle position (appr. 5 Ohm) and disabled by the

jumpers JP1 to JP4 (short-circuit). If a potentiometer shall be enabled, the corresponding jumper JPx has

to be removed. First you have to turn the potentiometer to the clockwise end position (clicking noise).

Afterwards you turn the potentiometer counterclockwise until the computed correction resistance is

adjusted.

6. Check the corners again. If required repeat the procedure.

•

Use suitable screwdriver !

•

Version 1: One turn corresponds to appr. 0.4 Ohm

Version 2: One turn corresponds to appr. 2 Ohm

•

Clockwise end position = 0 Ohm

•

Version 1: Counterclockwise end position = 10 Ohm

Version 2: Counterclockwise end position = 50 Ohm

Hints for Poti

adjustment:

•

Jumpers besides the enabled potentiometers must stay removed

Finally install the cover of the box.