5 coding of the load cells, 6 reference notes concerning electrostatics – Flintec ATEX User Manual

Page 4

Instruction and Operation Manual

for ATEX Approved Load Cells

Last revision: 24.10.2014

Revision: 9.5

Page 4 / 12

Date of 1st issue: 03.06.2002

2.4 Advice for Interconnections

a) Follow and respect the formation-regulations of the application-country.

E.g. in Germany follow the regulations EN 60079-14 and EN 61241-14.

b) It is ONLY permitted to use approved safety barriers or switch amplifiers for explosive-areas. In

Europe, it is a requirement to have an EC-Type Examination Certificate from a nominated certifying

body for the Zones 0 / 1 / 20 / 21.

c) The rated power, P

o

,of all excitation devices must be equal to or less than the power, P

i,

of one load cell.

d) The excitation voltage U

o

must be equal to or less than the voltage U

i

of one load cell.

e) The current, I

o

,of all excitation devices must be equal to or less than the current, I

i

,of one load cell.

f) To ensure a potential equalisation with -6w versions, a ground connection between the load cell

housing and the safet

y barrier’s ground connector is required. In these installations, the shield of the

connection cable is connected to ground potential at both ends.

g) On usual deliveries up to 10 meters, the inductance and capacitance per unit length of the connection

cables is negligible.

2.5 Coding of the Load Cells

The load cells have to be marked according to the following scheme:

AAA-BBB-CCC-DDEF-ZZ, e.g. SB8-100kg-C3-6wsc-12

AAA

=

Load cell type

BBB

=

Load cell maximum capacity

CCC

=

Accuracy class

DD

=

without marking = 4-wire; 6w = 6-wire

E

=

without marking = screen of cable not connected to load cell body,

s = screen of cable connected to load cell body

F

=

without marking = not coated, c = coated

ZZ

=

Cable length in plain text (in meter) if the load cell cable at delivery is longer than 10m

2.6 Reference notes concerning electrostatics

The load cells can be covered with a non-conductive protective coating as corrosion prevention. In the type

designation code the load cells are marked as "c" in the last position (F).

The free projected surface must not be larger than indicated in the following table after mounting the load

cells (types ***-*** ***-** *c) and propagating brush discharges must be avoided.

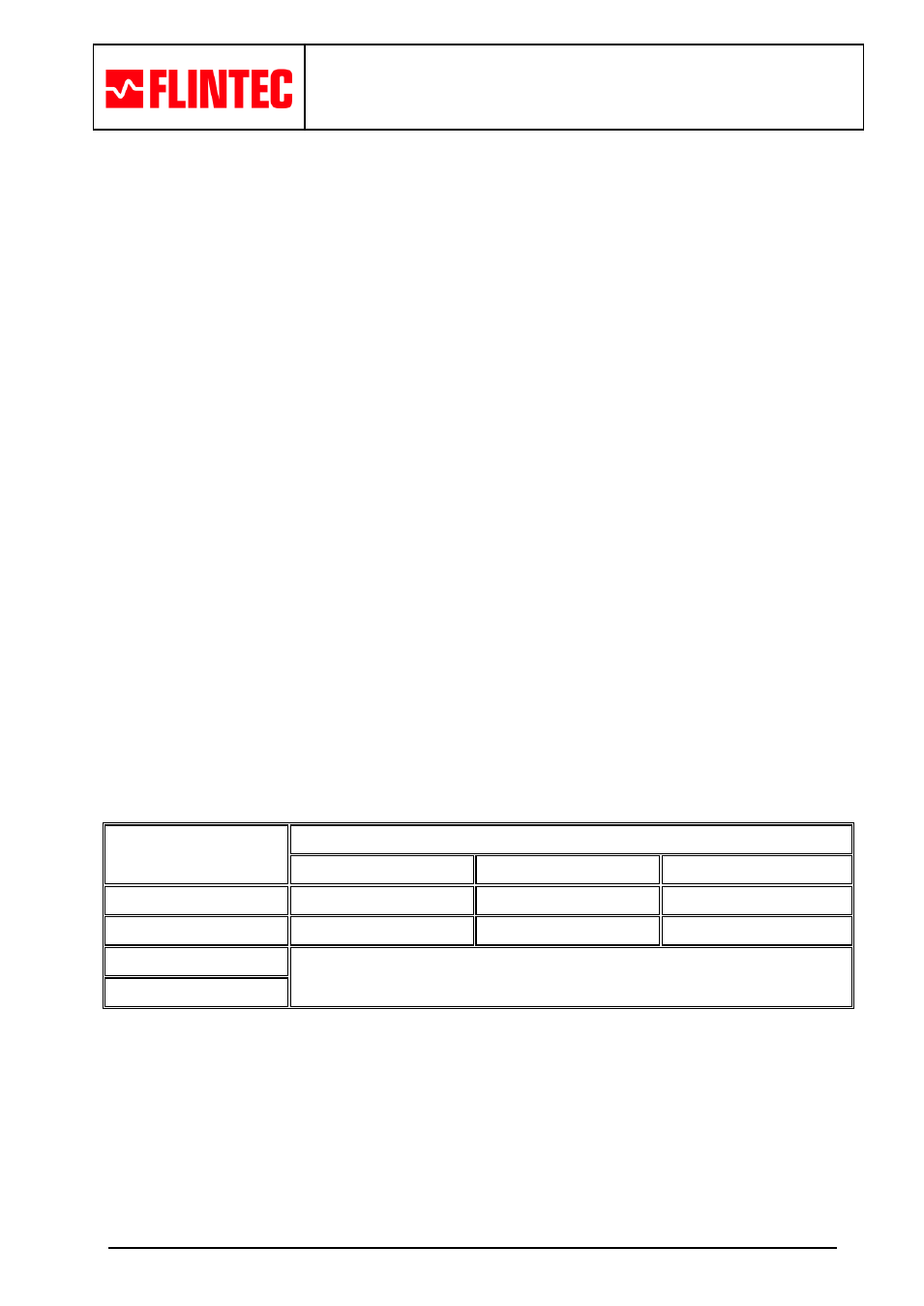

Used in:

Max. free projected surface

IIA

IIB

IIC

Zone 0

50 cm²

25 cm²

4 cm²

Zone 1 / 2

100 cm²

100 cm²

20 cm²

Zone 20

No limitation of size,

but exclusion of propagating brush discharges

Zone 21 / 22

If the limiting values of the at maximum tolerable free projected surface cannot be maintained, then

mounting can be done by the user (if propagating brush discharges can be eliminated) and he can point to

this risk on an ESD- warning label (Clean wet only !) on site and in his explosion protection document. In

Zone 2 the installation contractor may permit larger free surfaces on his own responsibility, in accordance

with the EX regulations