Maintenance – EDCO TILE SHARK User Manual

Page 7

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

E-TILESHARK-I-0913

Printed in USA

EDCO

©2013

Page 7

Maintenance

• All maintenance should be performed regularly and by qualified personnel only.

•

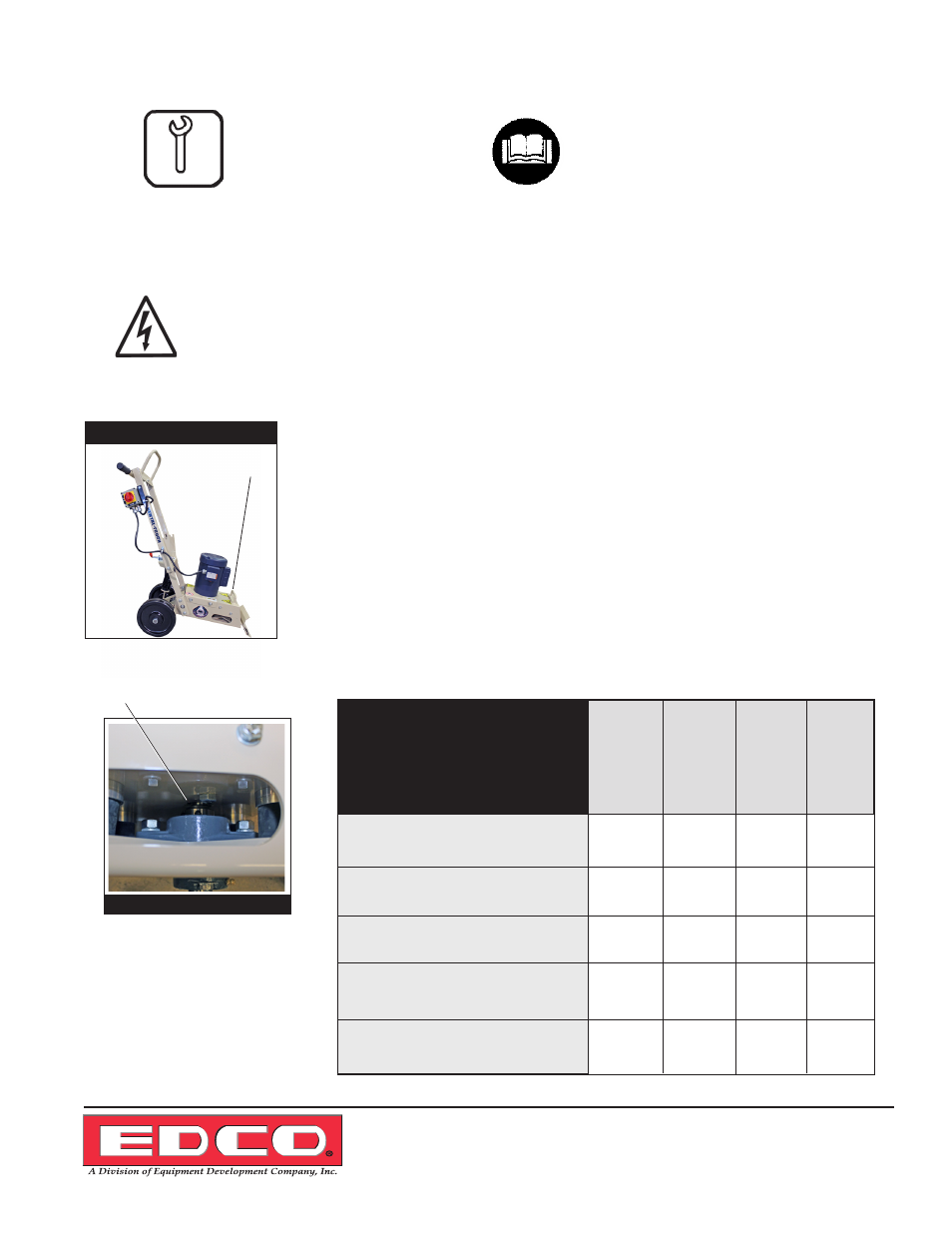

Grease striker plate driven shaft bearing every 4 hours of use. (Figure 7 & 7A).

Use Lubriplate #1444 High Temperature grease or equivalent.

• Lubricate the wheel bearings from time to time with an occasional drop or two of oil

to prevent binding.

• Keep the Tile Shark clean.

• Be sure the safety decals are readable and properly maintained on the machine.

• The Tile Shark can be stored or transported in the folded position as shown on

page 3 to save valuable cargo space. DO NOT store or transport with blade

attached.

Disconnect the power source at the machine and remove blade before

performing any maintenance.

Repairs are to be done

by authorized EDCO

Dealers only.

Read and follow instructions

in the engine owner’s man-

ual.

Figure 7

Grease point

under cover

Grease point

inside opening

Figure 7A

Visual Inspection of Machine and

Power Cord

Before

Operation

As necessary (prevents bind

-

ing)

After Each

Use

Quick Reference

For Maintaining

the Tile Shark

X

X

X

X

Oil wheel bearings

(with light weight oil)

Clean dust, dirt and mastics

from machine

Inspect Blade

X

Grease Striker Plate

Driver Shaft Bearings (2 ea)

Every 4 Hours