Maintenance – EDCO TG-7 User Manual

Page 7

E-TMC7,EDG7,TG7-I-0710

Printed in USA

TVW

©2010

Page 7

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

A Division of Equipment Development Company, Inc.

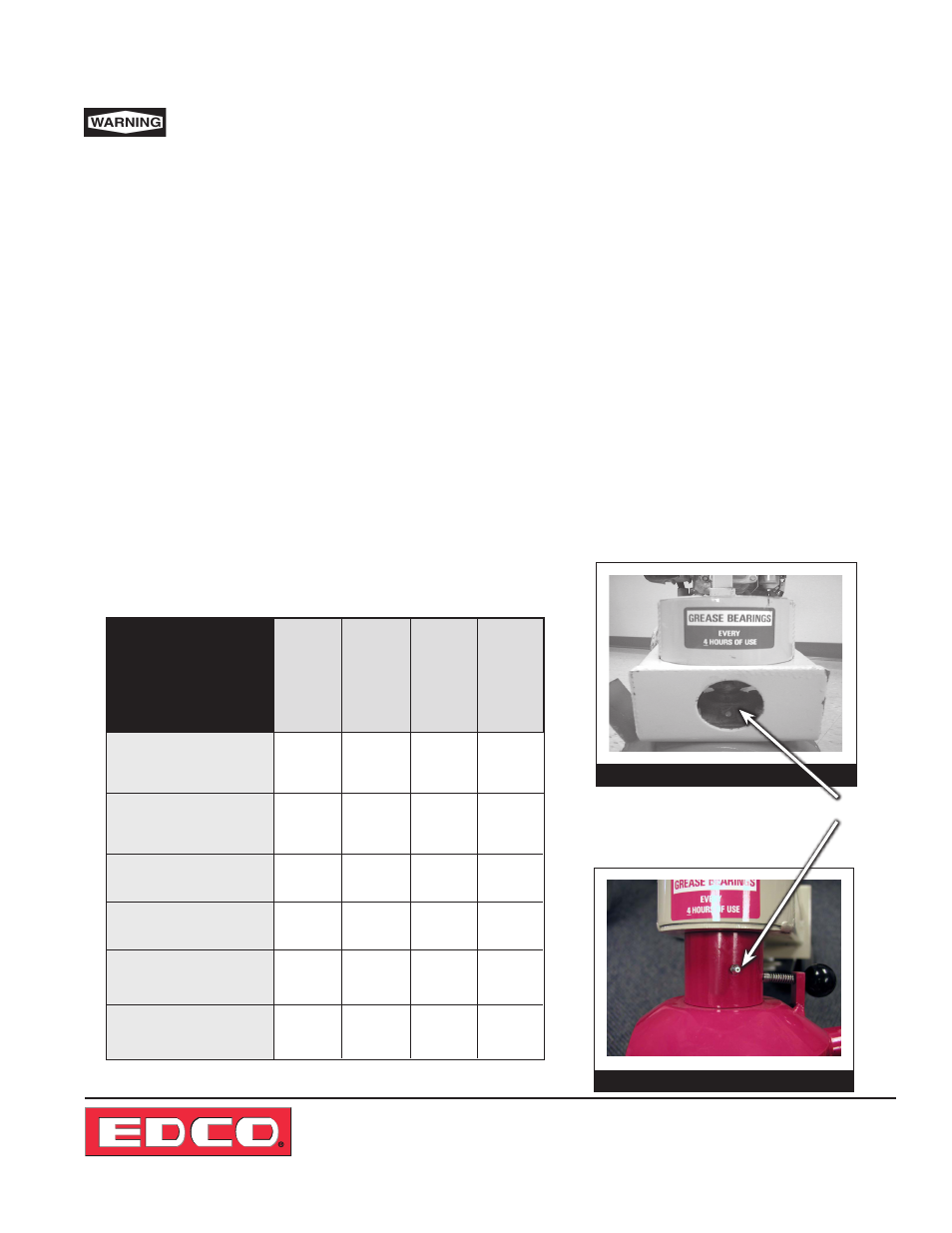

Figure 4A

Maintenance

Make sure the throttle is completely closed (full stop position) to insure the engine will not accidently

fire (kick back) while performing any maintenance.

• All maintenance should be performed regularly and by qualified personnel only.

• Never work under equipment without first properly securing the equipment to prevent it from moving or falling.

Always work on a flat and level surface.

• Grease disc bearings every 4 hours of use. To access the bearings on the EDG-7 and TG-7, simply remove the

front cap-plug cover (Figure 4) with a flat screwdriver. Both of the bearings are self-aligning, sealed flange

mounted, equipped with grease fittings. To access the fitting on the TMC-7 refer to (Figure 4A) . These bearings

are tapered roller bearings lubricated with High Temp Lubriplate No. 930-AA, or equivalent bearing grease. Do

not over lubricate. Be sure to clean up any excess grease after lubricating the bearings. These bearings can

occassionally require adjustment. If it is evident that these bearing need adjustment they can be accessed by

removing the belt cover.

• Lubricate the wheel bearings from time to time with an occasional drop or two of oil to prevent binding.

• To tension the belt, the Grinders are outfitted with a tensioning pulley (Figure 3). Proper belt tension must be

maintained to transmit the motor power to the grinding disc. Damage to the motor will occur and disk life

shortened if belts are not kept at the proper tension.

• Keep the Grinders clean. Be sure the safety decals are readable and properly maintained on the machine.

Visual Inspection of

Entire Machine

Before

Operation

Daily

As Required

After Each

Use

Quick

Reference

For Maintaining

Grinders

X

X

X

X

X

Inspect Belt and

Belt Tensioning

Clean dust and dirt

off machine

Grease Bearings

Inspect

Diamond Disc

Engine Air Filter

X

Grease fittings

Figure 4