Replacing the diamond grinding disc, For dry grinding, Inspect drive belt – EDCO TG-7 User Manual

Page 6

E-TMC7,EDG7,TG7-I-0710

Printed in USA

©2010

TVW

Page 6

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com

Email: [email protected]

A Division of Equipment Development Company, Inc.

Replacing the Diamond Grinding Disc:

• Make sure the throttle is

fully closed (full stop position) to insure there will

be no accidental engine starting while cleaning or replacing the disc.

• To gain access to the disc, push down on the handle in the rear

optional position (Figure 1) and pivot the unit back on the wheels until it

comes to rest on the handle. (The belt tensioning bolt is also visible from this

position.)

• Unbolt the diamond disc and remove the disc.

• Replace with a new disc by simply reversing the procedure.

For Dry Grinding:

Check materials being removed to determine if they are listed on an EPA hazardous substance list. A

breathing respirator is required to help protect the operator.

• The EDCO VAC-100, VAC-160 and VAC-150 have available optional HEPA filter kits designed to be

used when removing hazardous materials. Standard, shop-vac style vacuums are not capable of extended operation.

In addition, these standard vacs use paper bag filters that can clog and overload the vacuum motor.

• Dry grinding creates a large volume of airborne dust. The edgers are equipped with a 1-1/2” vacuum port for at-

taching a high volume industrial vacuum capable of removing particles to three microns. If the materials involved are

hazardous, or unknown and assumed hazardous, the operator must assume responsibility for the proper handling and

disposal of the hazardous material.

Note: Hazardous debris, including vacuum filters, must be disposed of properly according to OSHA and government

standards.

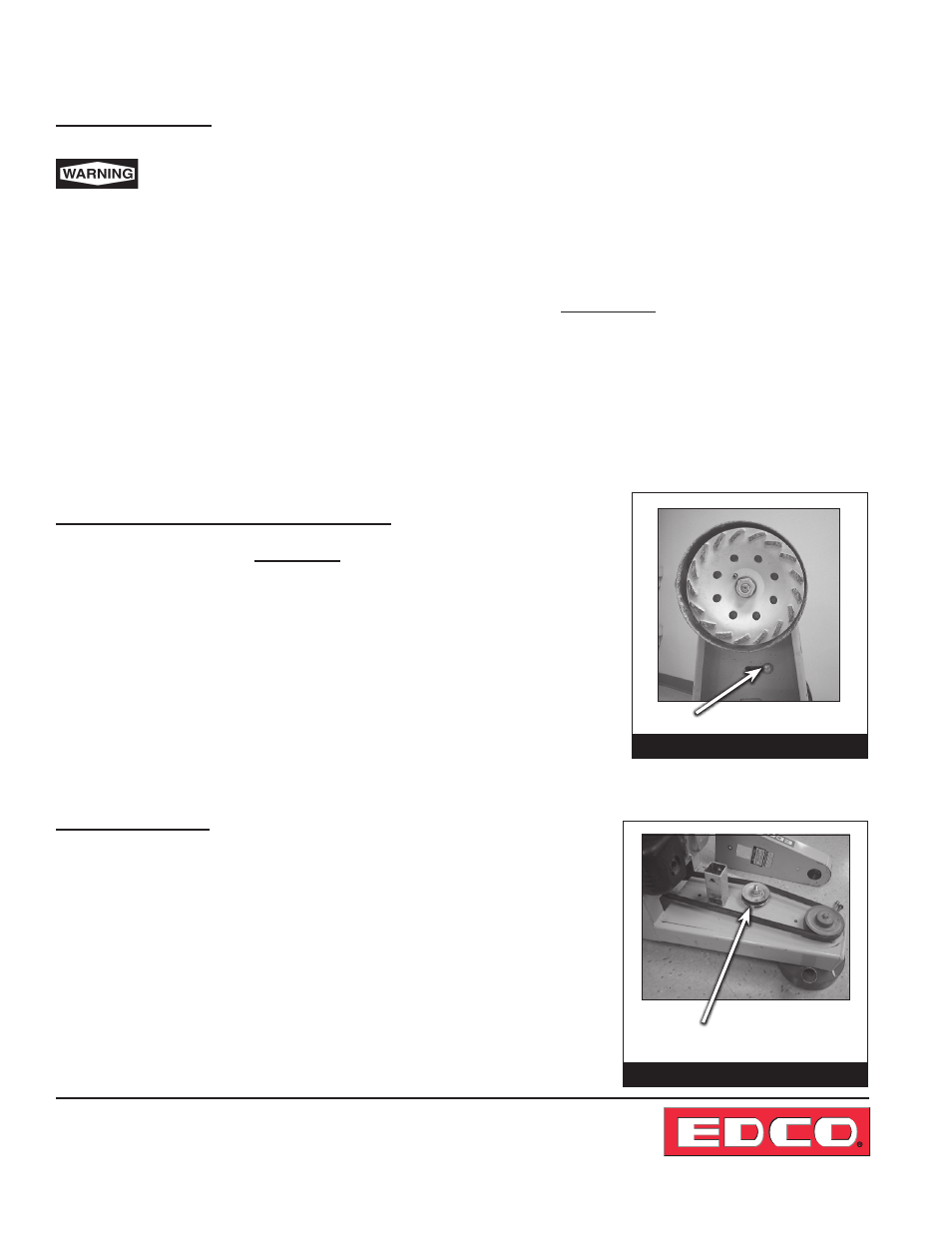

Inspect drive belt

:

• Check belt tension. On new equipment, and after installing a new belt, the

belt should be retensioned after the first four hours of use. A damaged,

stretched, or worn belt should be replaced with a new one. (Figure 3 -

Shown with belt cover removed.)

• Adjust belt tension (Figure 3). Loosen belt tensioning bolt (Figure 2) and slide

pulley to provide more tension against drive belt.

Figure 3

Belt Tensioning Pulley

Figure 2

Belt Tensioning Bolt