Operating instructions – ebm-papst W4D710-GF01-01 User Manual

Page 7

Operating instructions

W4D710-GF01-01

Translation of the original operating instructions

4.2.4 Frequency inverter

Please use a frequency converter only after consultation with ebm-papst.

Fit sinusoidal filters that work on all poles (live-live and live-

earth) between the frequency inverter and the motor for

operation with frequency inverters.

Depending on how the device is installed, noises may occur.

Heating of the motor due to use of a frequency converter must be

checked in the application by the customer.

4.3 Connection in terminal box

4.3.1 Preparing connection lines for the connection

Strip the cable just enough so that the screwed cable gland is tight and

the terminals are relieved of strain. Tightening torque, see chapter 3.1

Product drawing.

4.3.2 Connecting cables with terminals

; Remove the cap from the screwed cable gland.

Remove the cap only in those places where cables are inserted.

; Insert the line(s) (not included in the standard scope of delivery) into

the terminal box.

; First connect the "PE" (protective earth) connection.

; Connect the lines to the corresponding terminals.

; Connect the thermal overload protector (TOP).

Use a screwdriver to do so.

During the connection work, ensure that no cables splice off.

The terminal strip is equipped with a penetration prevention device.

; Insert the strands until they meet resistance.

; Seal the terminal box.

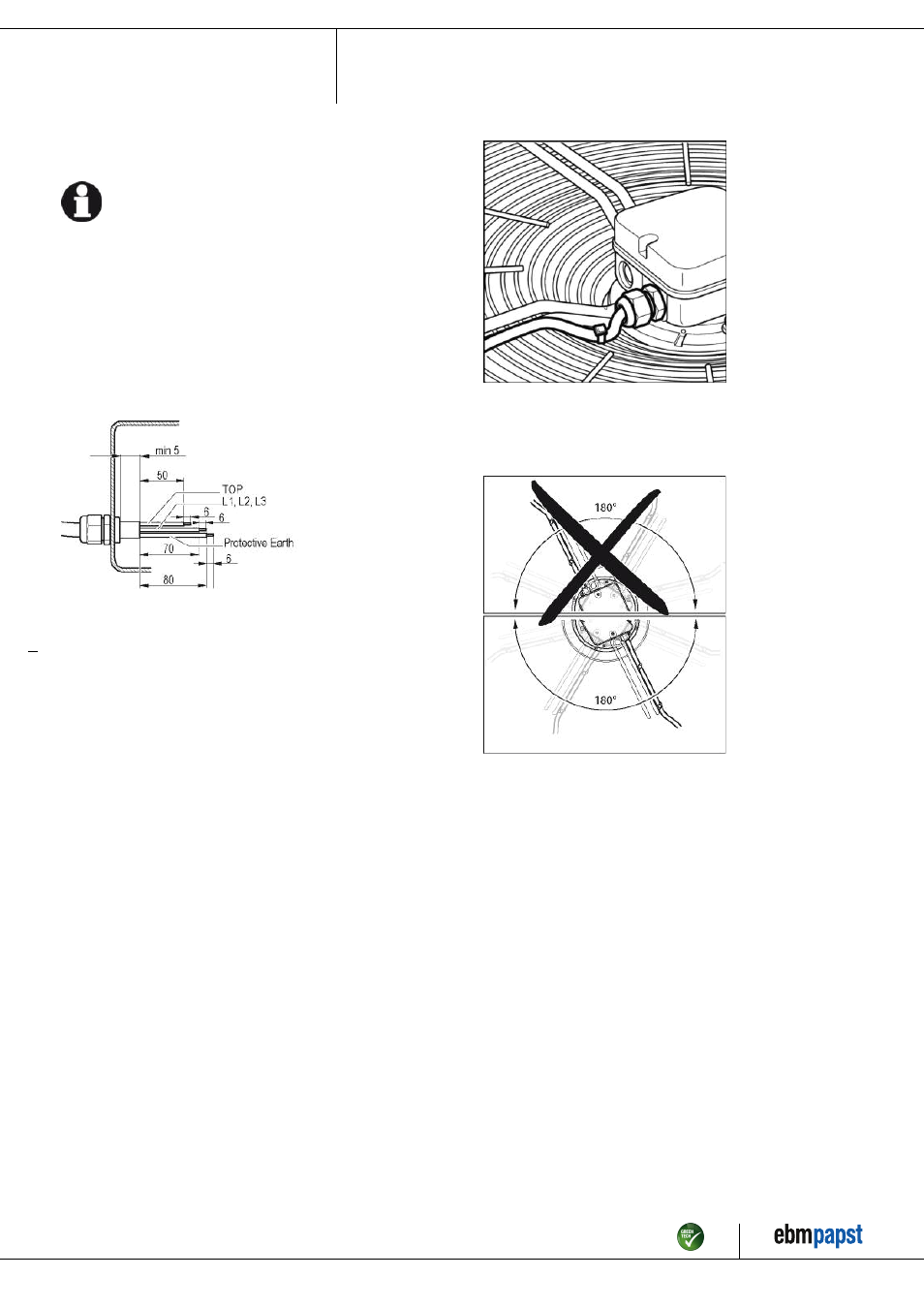

4.3.3 Cable routing

No water may penetrate along the cable in the direction of the cable gland.

Fans installed lying flat

Make sure that the cable is routed in the form of a loop (water trap).

Fig. 2: Fan installed lying flat, cable routed as a water trap.

Fans installed in upright position

When routing the cable, ensure that the screwed cable glands are

arranged at the bottom. The cables must always be routed downwards.

Fig. 3: Cable routing for fans installed upright.

4.3.4 Motor protection

CAUTION

Voltage

The device is a built-in component with no isolating switch.

→ Connect the device to a suitable tripping device.

→ Only connect the device to circuits which can be de-

energised with an all-pole disconnection switch.

→ When working on the device, the system/machine in

which the device is installed must be secured so as to

prevent it from being switched back on.

NOTE

Lack of motor protection

Without motor protection, the motor can overheat and suffer

damage.

→ Connect up the thermal overload protector installed in the coil.

The motors are equipped with thermal overload protectors to protect the

devices.

Check to make sure that the thermal overload protector is correctly

connected before each operation.

Failure to connect up the thermal overload protector correctly will

invalidate your warranty claim.

Item no. 10935-5-9970 · Revision 82513 · Release 2014-06-10 · Page 7 / 10

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com