Kenmore 564.8815022 User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Pressure Vessel

• Do not remove valve from CO

2 cylinder.

• C

02 cylinder should be handled only by trained, experi

enced personnel and in accordance with the safe handl

ing practices recommended by the current C.G.A. pam

phlet P-1* *.

• Keep out of reach of children.

• Visually inspect monthly or more frequently. If cylinder

shows evidence of corrosion or mechanical damage, it

should be inspected and tested in accordance with the

current C.G.A. pamphlets C-1* or C-6* or it should be

replaced.

CHARGE ONLY WITH DRY CARBON DIOXIDE

• Do not charge with carbon dioxide unless the pressure

rating stamped on COj cylinder is 1800 PSI or greater.

• When charged with carbon dioxide do not exceed a fill

density of 68%. (Fill density is a percent ratio of the

weight of gas in the cylinder to the weight of water that

the cylinder will hold at 60°F).

• If cylinder has been exposed to temperatures in excess

of 350°R, it must be destroyed.

Improper use of cylinder could cause serious bodily injury

or property damage.

• C.G.A. pamphlets are published by the Compressed

Gas Association, 500 5th Ave., New York, N Y.

a.

Your C02 cylinder is shipped empty to avoid any possible

accident during transportation. When you purchase the

first keg of beer, get CO

2 cylinder filled by your beer

distributor.

b.

Follow the procedure on the inside front cover page of

“Draught Beer Facts" book for installation of CO

2 regulator

to CO

2 cylinder.

NOTE:

Shutoff valve on CO

2 cylinder may be different in

shape. Do not open shutoff valve until pressure

tube, keg tapper and beer keg are connected to

COj regulator.

c.

Connect pressure tube (clear plastic tube) to

CO^

reg

ulator at nipple. Secure connection with hose clamp. To do

this, place hose clamp over tube and squeeze both ends

of hose clamp so that locking teeth will mate.

d.

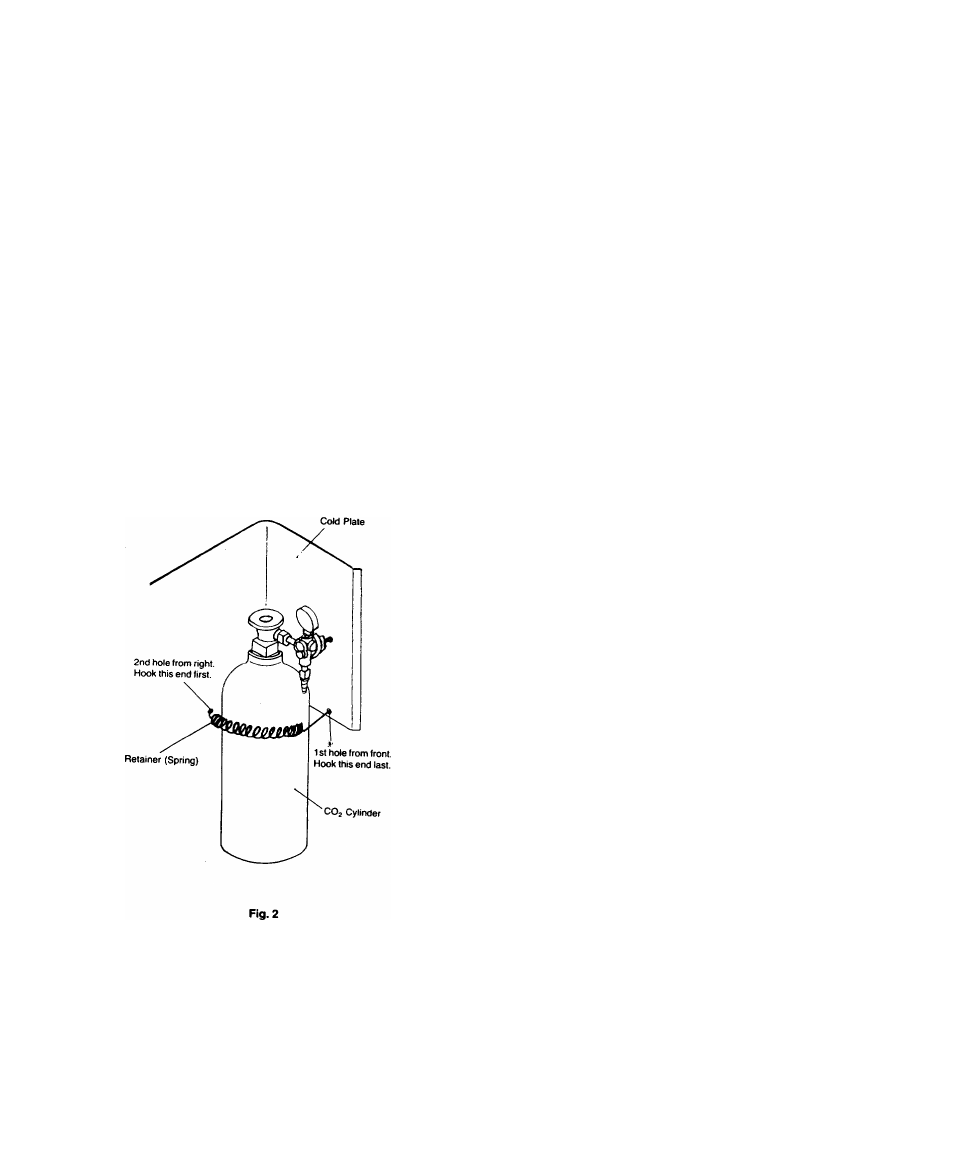

Place COj cylinder at right rear corner inside beer dis

penser cabinet in upright position. Fasten CO

2 cylinder

with COj cylinder retainer (spring) provided. Hook both

ends of retainer to holes in cold plate. (See Fig. 2.)

WARNING:

To avoid personal injury and/or property dam

age, always secure COj cylinder with re

tainer to prevent it from falling. Should CO

2

cylinder valve become accidentally damaged

or broken off, C

02 cylinder can become an

unguided missile.

2. Installing Keg Tapper and Beer Keg.

a. The Sankey type keg tapper supplied with beer dispenser

is the most widely used in the United States. However,

some other type keg tappers, such as Golden-Gate, Euro

pean Sankey or Hoff-Stevens are still being used. Before

installing keg tapper, check with your beer distributor to

make sure that the Sankey type keg tapper can be used.

If you need a keg tapper other than Sankey type, it is rec

ommended to purchase the tapper you need from your

beer distributor keeping the Sankey type keg tapper for fu

ture use because the Sankey system is becoming more

widely used.

If you wish to have the Sankey type keg tapper exchanged

with another type keg tapper, please return collect the

Sankey type keg tapper to the address below specifying

the type of keg tapper you need:

Sanyo E & E Corp.

2001 Sanyo Avenue

San Diego. California 92173

ATTN:

Customer Service Dept.

Make sure shutoff valve on

CO^

regulator is in closed posi

tion. Connect pressure tube to nipple of keg tapper (use

hose clamp). Connect beer tube from draft arm to keg tap

per (fasten securely with washer and wingnut).

Make sure that beer faucet and keg tapper are in closed

position, then tap a keg. Open keg tapper valve. (For more

detailed procedures for Items B and C, refer to attached

leaflet.)

Make sure the keg is properly tapped, then open shutoff

valve on CO

2 regulator. To install beer keg into cabinet fol

low the steps below (see Fig. 3).

—

•

Wet the surface of keg supports (wooden plates)

•

Lean keg supports on the front bottom edge of

cabinet.

•

Place keg on supports supportir>g keg by hands.

•

Push the upper part of keg to stand in upright position

then slide keg supports into cabinet.

•

Make sure that keg and beer tube do not touch cold

plate and that keg and keg supports are properly

positioned not to interfere with door closing.

Release air caught in draft arm assembly by opening beer

faucet until foam appears. Now dispenser is ready to us.

b.

-3-