Operation, Installation – Campbell Hausfeld FP2091 User Manual

Page 3

FP2090, FP2091, FP2094 Series

3

2. If repair or replacement of cord or

plug is necessary, do not connect

grounding wire to either flat blade

terminal. The wire with insulation

having an external surface that is

green (with or without yellow

stripes) is the grounding wire.

Never

connect green (or green and yellow) wire

to a live terminal.

3. Check with a qualified electrician or

serviceman if grounding instructions

are not completely understood, or if

in doubt as to whether product is

properly grounded. Do not modify

plug provided; if it will not fit outlet,

have proper outlet installed by a

qualified electrician.

Overheating, short circuiting and fire

damage will result from inadequate

wiring, etc.

Operation

Definition of Terms

ON / OFF Switch ( I / O ) - Push switch

to the ON ( I ) position to turn

compressor on. Push switch to the OFF

( O ) position to turn compressor off.

This switch should be in the OFF ( O )

position when connecting /

disconnecting power cord from

electrical outlet or when changing tools.

Pressure Switch (located internally)-

When the compressor is turned ON,

this switch will shut compressor off

automatically when tank pressure

reaches maximum shut-off / cut-out

pressure. If compressor remains on and

air is depleted from tank, this switch

will allow compressor to automatically

restart at the restart / cut-in pressure.

Regulator - The regulator controls the

amount of air pressure released at the

hose outlet. Turning the regulator knob

clockwise (to the right) will increase air

pressure at the outlet. Turning the knob

counter-clockwise (to the left) will

lower air pressure to the outlet. Turning

knob fully counter-clockwise will shut

off flow of air completely.

Pressure Gauges - There are two

gauges located next to the regulator.

These gauges read air pressure in

pounds per square inch (psi) The larger

gauge shows pressure at the outlet.

Make sure this gauge reads ZERO (by

adjusting the regulator) BEFORE

changing air tools or disconnecting hose

from outlet. The small gauge shows

pressure in the tank indicating

compressor is building pressure properly.

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Handle - Designed to move the

compressor.

Drain Valve - This valve is located on

the bottom of the tank. Use this valve

to drain moisture from the tank daily

to reduce the risk of corrosion.

Motor Reset - (not shown, located

inside motor). Designed to keep the

motor from overheating. The motor

has an auto reset protector. To reset

once the motor has cooled, turn the

switch to the OFF position, then to the

ON position.

This

compressor is equipped with an overload

protector which will shut off motor if it

becomes overloaded.

If the

overload protector is actuated, the motor

must be allowed to cool down for

approximately 30 minutes before it will

reset.

LUBRICATION

This is an oilless product and DOES

NOT require lubrication to operate.

BEFORE FIRST STARTUP

BREAK-IN PROCEDURE

(Complete this procedure before using

compressor for the first time. Once

completed, it is not necessary to repeat.)

1. Turn regulator knob fully clockwise

(to the right) to open air flow.

2. Do not attach a hose or any other

fitting to the compressor.

3. Turn on/off switch to OFF position.

4. Plug in power cord.

5. Turn on/off switch to ON position.

Allow compressor to run for 5

minutes.

6. Turn on/off switch to OFF position.

ON/OFF Switch

Drain Valve

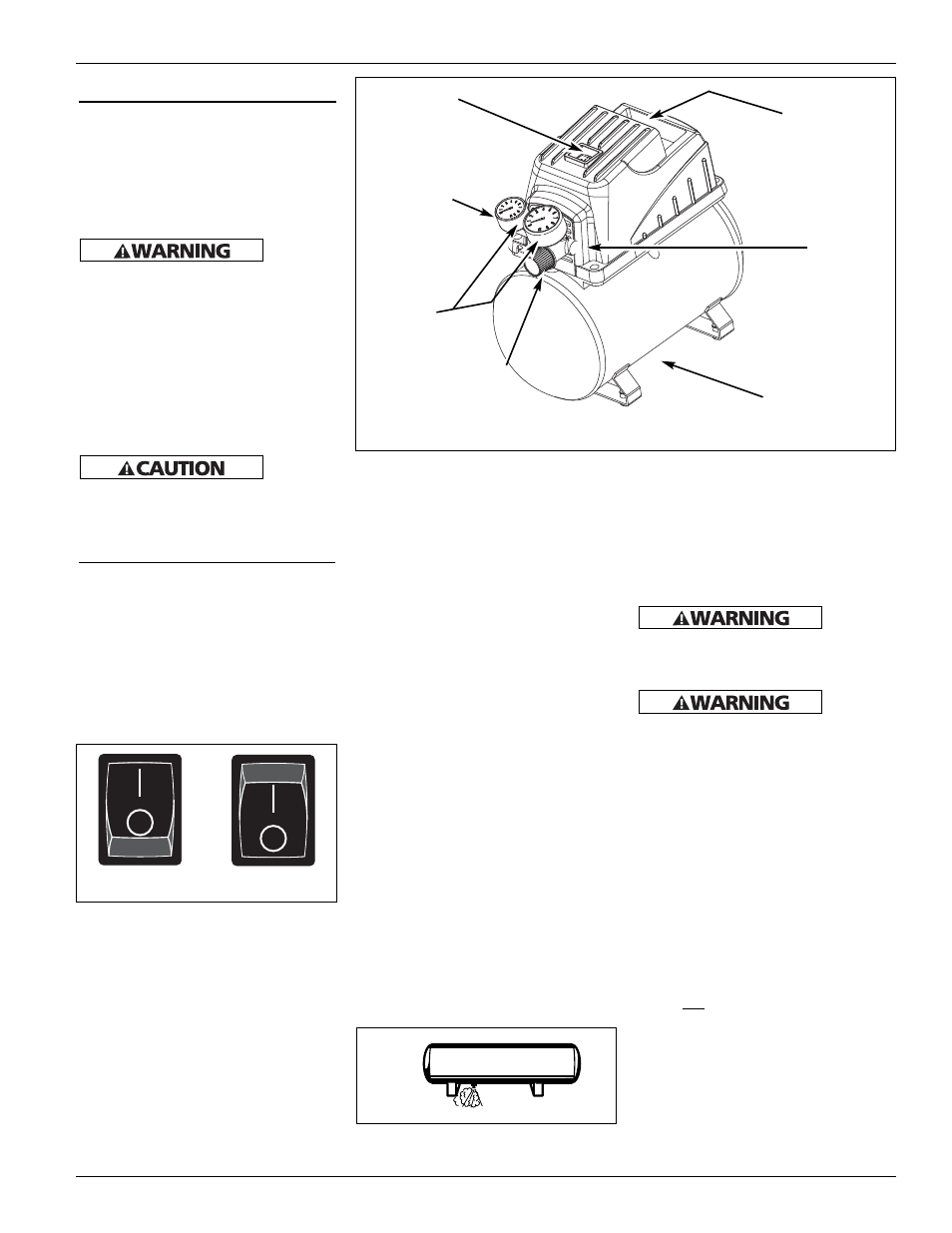

Figure 2 - Unit Identification

Handle

Pressure

Gauges

Safety Valve

Air Outlet

Regulator

OFF Position

Figure 3

ON Position

Figure 4

Installation

(Continued)