A warning, A caution, Gas conversion – Whirlpool FGP335BL2 User Manual

Page 4: Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

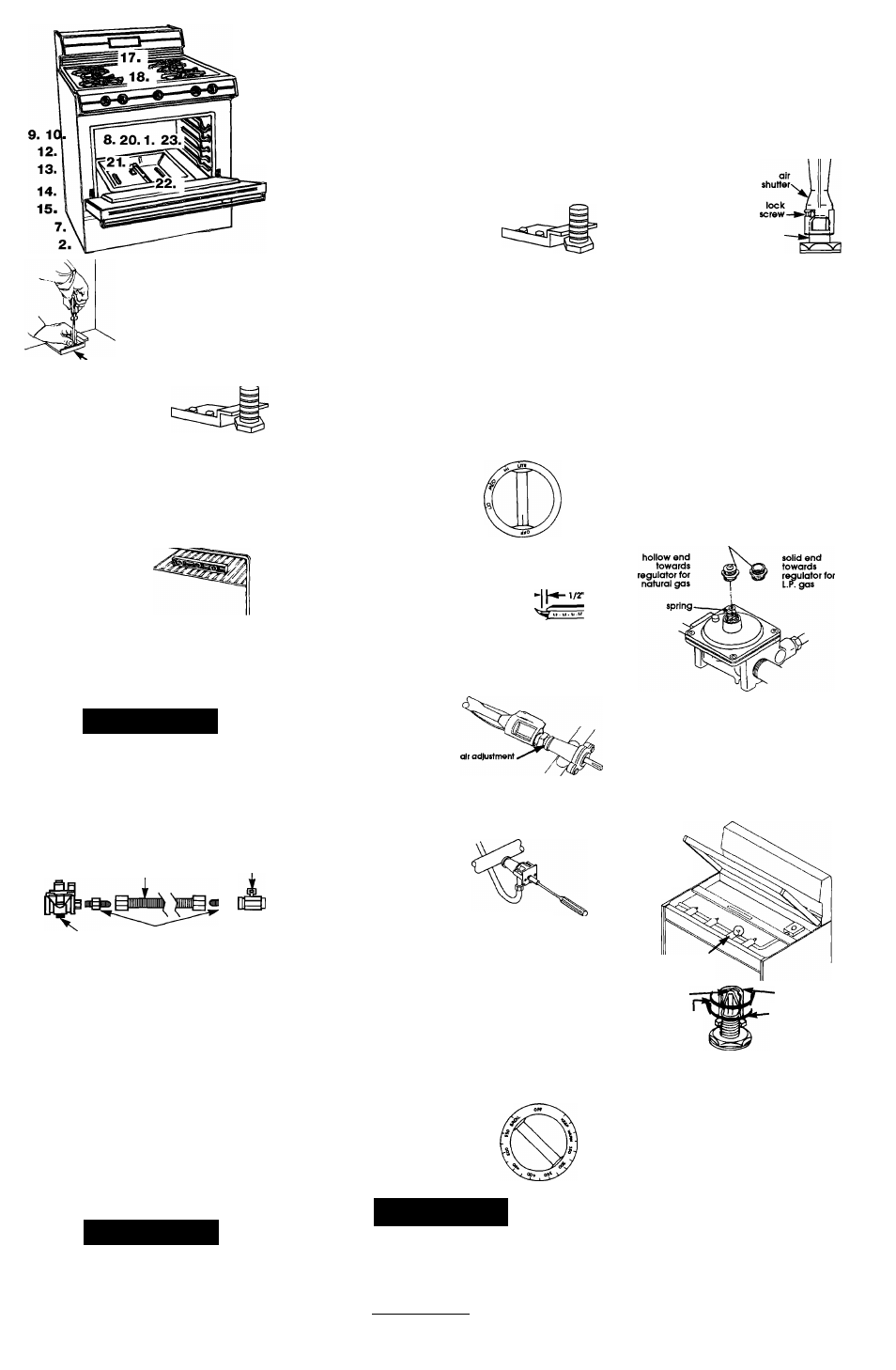

16. 19.

Numbers

correspond

to steps.

turned-up flange

■ Place anti-tip

bracket on floor with turned-

up flange facing the front.

Line up holes in anti-tip

bracket with holes drilled in

floor. Use screws to attach

bracket to floor. Repeat

with right anti-tip bracket.

■ ■ Remove shipping

base, cardboard or

hardboard from under

range. Remove storage

drawer. Carefully move range into position.

Grasp rear of range and carefully try to tip

range forward. If range tips forward, leveling

legs are NOT properly engaged in anti-tip

brackets. Remove and reposition braokets

so leveling legs will fit properly under end

flanges of brackets.

8

Place rack in

oven. Place level on

rack, first side to side;

then front to back to

check that range is

level. If range is not level, adjust legs up or

down. If needed, pull range forward until

rear leveling legs can be adjusted. Push

range back into position and check that

range is level.

Note: Oven must be level for satisfactory

baking conditions.

A WARNING

Fire Hazard

Do Not make connection too tight. The

regulator Is die cast.

Overtightening may crack the regulator,

resulting In a gas leak and possible fire or

explosion.

All connections must be wrench-

tightened.

flexible connector

manual shutoff

valve

pressure

regulator

1/2" flare union adapters

■ Pull range forward to make gas

connections. Assemble the flexible

connector from the gas supply pipe to the

pressure regulator, located on the lower

right hand side on the back of the range, in

this order: shutoff valve, 1 /2" flare union

adapter, flexible connector, t /2" flare union

adapter. Seal all openings in floor or wall

wherever range is installed.

10

Use pipe-joint compound made

for use with Natural and L.P. gas to seal all

gas connections. If flexible connectors are

used, be certain connector is not kinked.

11

b

Open the shutoff valve in the

gas supply line. Wait a few minutes for gas to

move through the gas line.

A WARNING

Fire Hazard

Do Not use an open flame to test for leaks

from gas connections.

Checking for leaks with a flame may

result In a fire or explosion.

12

B

Use a brush and liquid detergent

to test all gas connections for leaks. Bubbles

around connections wiii indicate a leak. If a

leak appears, shut off gas valve controls and

adjust connections. Then check

connections again. NEVER TEST FOR GAS

LEAKS WITH A MATCH OR OTHER FLAME.

Clean all detergent solution from range.

■

B

Plug power supply cord into

grounded outlet.

Id

■

B

Move range into final

position. Grasp rear of range and

carefully try to tip range forward

to check that both rear leveling

legs are engaged in anti-tip brackets.

15

Turn power supply on to range.

Electronic

Ignition

System

—

initial

lighting

and

gas

flame

adjustments.

When the cooktop control knob is turned to

"LITE" position, the system creates a spark to

light the burner. This sparking continues until

the control knob is turned to the desired

setting. When the oven control is turned to

the desired setting, a glow bar heats up

bright orange and Ignites the gas. No

sparking occurs and the glow bar remains

on while the burner operates.

16

Check the

operation of the cooktop

burners. Push in and turn

each control knob to "LITE"

position. The flame should light

within 4 seconds. Do Not leave the knob In

the “LITE” position after burner lights.

17

After burner lights, turn

control knob to "HI" position. Check

each cooktop burner for proper flame.

The small inner cone should have a very

distinct blue flame approximately 1 /2"

long. The outer cone Is not as distinct as

the inner cone.

18.

If burners

need adjusting for proper

flame, remove burner

grates and carefully liff

up the maintop. Adjust

the air shutter to the

widest opening that will

produce a sharp blue flame that does not lift

or blow off of the burner. Repeat as

necessary with each burner.

19

Push in and turn

the control knob to the

"LITE" position and then to

the "LO" position. The low

flame should be a

minimum, steady, blue

flame. To adjust the burner,

remove the control knob and turn the

adjustment screw in the center of the valve

stem. Check the adjustment by turning the

control knob from "HI" to "LO" several times.

The burner is properly adjusted when the low

flame remains steady and the burner does

not go out. Check each burner.

20

.

Remove oven rack. Remove

oven screws at rear of oven bottom. Pull

oven bottom rear up and remove front of

oven bottom from oven front. Remove oven

bottom. Remove burner baffle.

Check the operation of the oven burner.

Push in and turn temperature control

knob counterclockwise to 300°F.

The oven burner should light In

50 - 60 seconds. This delay Is

normal. The oven safety valve

requires a certain time before it

will open and allow gas to flow.

A

CAUTION

Product Damage

• Do Not Insert any object Into the

openings of the protective shield that

surrounds the Ignitor.

• Do Not clean the area.

Failure to follow these Instructions could

result In product damage.___________

21

Check the oven burner

for proper flame. This flame should

have a 1" long inner cone of bluish-

green, with an outer mantle of dark

blue, and should be clean and soft

in character. No yellow tips, blowing

or lifting of flame should occur.

22

If oven flame

needs to be adjusted,

locate the air shutter near

the center rear of the

oven burner. Loosen the

lock screw and adjust

the air shutter until the

proper flame appears.

Tighten screw.

23.

Replace the oven burner baffle,

oven bottom, oven racks and broiler drawer.

orifice

hood

To get the most efficient use from

your new range, read your Use and

Care Guide. Keep instaiiotion

instructions and Guide close to the

range for easy reference.

Gas conversion

The serial rating plate, located under the

maintop, specifies the type of gas this range

was set to use. Conversion should be done

by a qualified installer.

Natural to L.P. gas

Aa Convert the pressure regulator. Do Not

remove the pressure regulator.

cap

1. Unscrew the cap from the pressure

regulator. Be sure spring stays in place.

2. Turn the cap over so the hollow end faces

outward.

3. Replace the cap of the regulator. The

letters L.P. should be visible on exposed

end of the cap.

B.

Convert surface burner valves.

cooktop

(shown in raised

position)

4 surface

burner

hoods

NAT. GAS

increases gas

increases (lame size

(preset at factory for

rratural gas)

hood

L.P. GAS

decreases gas

decreases flame size

1. Lift and lock cooktop in up position.

2. Use 1 /2' wrench to turn hood clockwise

until snug (approximately 2-1/2 turns).

Do Not overtighten.

W ■ Convert oven burner.

1. Remove oven bottom hold-down screws

at rear of oven bottom. Pull up at rear,

and remove front of oven bottom from

oven front frame. Pull the oven bottom

straight out of the oven. Remove burner

baffle.

2. Use 1 /2" wrench to turn the hood

clockwise (approximately 2-1/2 turns), until

snug against the pin. Do Not overtighten.

3. Turn thermostat control knob to 300°F. The

oven burner flame should be steady and

approximately 1" long with no yellow or

orange tips.

Panel C