For countertops with a backsplash, A warning, To prevent tipping, install the anti-tip bracket – Whirlpool SS373PEX1 User Manual

Page 5: A caution, Floor damage, Fire hazard, Ail connections must be wrench- tightened

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

rear wall

transition

3/4" min.,

7/8" max.

Without

backsplash

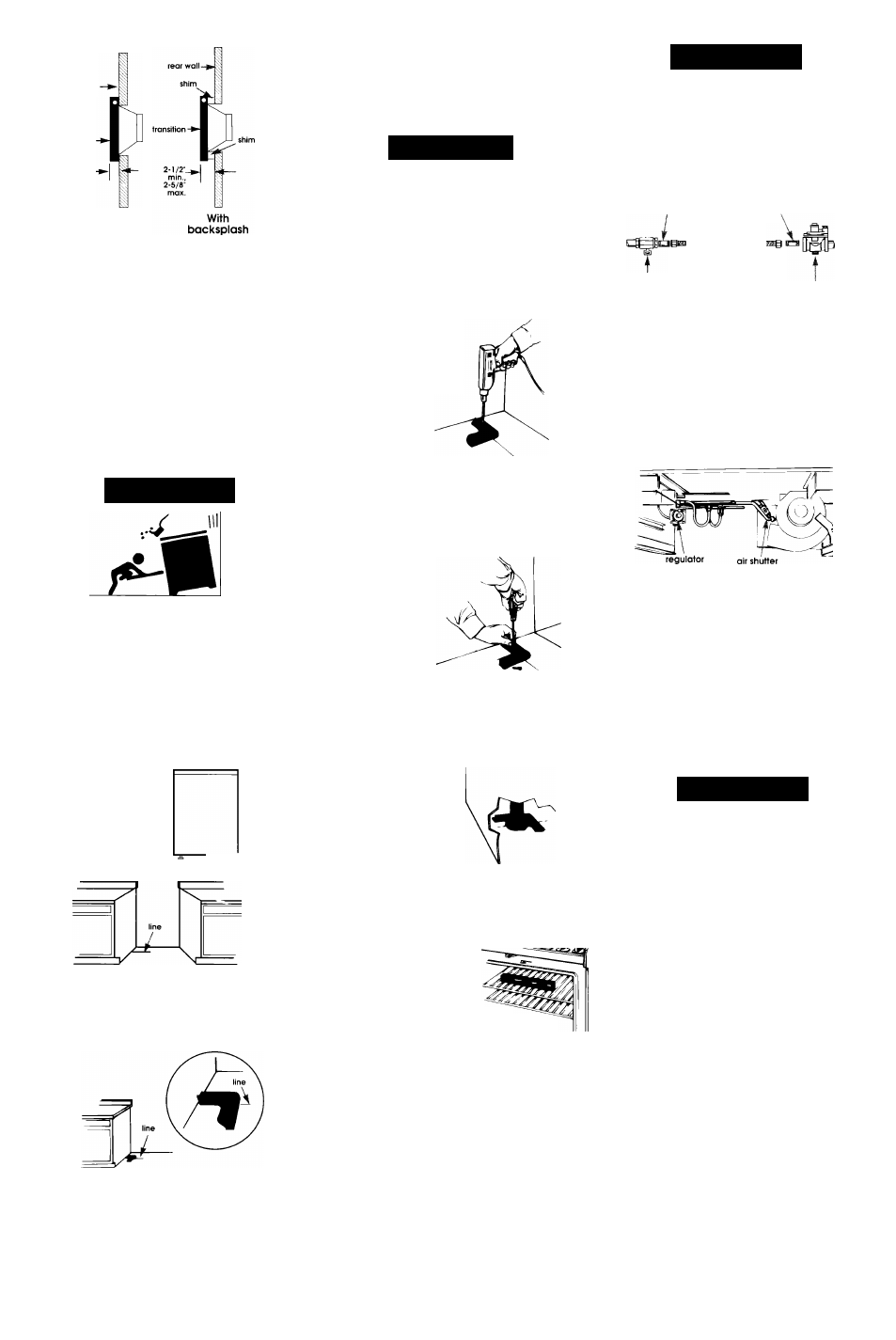

For countertops with a backsplash,

the distance from the rear wall to the

gasket must be at least 2-1/2";

2-5/8“ maximum.

Attach wall duct to range fan exhaust

with wall duct directed toward rear of

range.

Secure wall/floor duct plate to wall

duct using screws supplied.

8a.

For floor or left side venting: Follow

instructions supplied with floor vent kit

or left side vent kit.

A WARNING

To prevent tipping, install the anti-tip

bracket.

Save these Installation Instructions.

If range is moved to a new location,

the anti-tip bracket must be

removed and reinstalled in the new

location.

One anti-tip bracket must be installed,

• Measure the

distance from

the center of the

leveling leg to

the turthest point

that extends

trom the back of

the range.

leveling leg —►*

• Mark on the floor the distance just

measured trom the rear of the cabinet

opening or wall where the range will be

installed. Additional space may be

needed for gas line located behind the

range.

• Place one end of the anti-tip

bracket on the floor against the

cabinet side so that the inside edge

of the bracket is aligned with the line

drawn.

10

.

Use a pencil to mark the two mounting

screw hole locations on the anti-tip

bracket. Remove bracket from

position.

A CAUTION

Floor Damage

• Contact a qualified floor covering

installer for the best procedure to drill

mounting holes through your type of

floor covering.

> Before moving range across floor,

check that range is on shipping base

or slide range onto cardboard or

hardboard.

Failure to follow these instructions may

result in damage to floor covering.

1 1

.

cabinet

wall

To mount anti

tip bracket to

wood floor, drill

a 3/32" hole at

each mounting

screw location.

To mount anti-tip bracket to concrete or

ceramic floor, use a masonry drill bit to

drill 3/16" holes at eaoh mounting

screw location. Tap plastic anchors into

mounting holes in floor with hammer.

12

.

Line up holes in

anti-tip bracket

with holes in

floor. Use the

sorews provided

to fasten the

anti-tip bracket

to floor.

13

Move range close to final position.

Remove the shipping base, cardboard

or hardboard from under the range.

Plug power supply cord into grounded

outlet.

14.

Carefully move range

into final position.

Remove storage

drawer or look

underneath range. (A

flashlight may be needed.) Check that

the rear leveling leg is engaged in the

anti-tip bracket. If leveling leg is not

properly engaged, remove and

reposition the bracket to insure that the

leveling leg fits properly in the bracket.

15.

Place rack in oven. Place

level on rack, first side to

side; then front to back. If range

is not level, pull the range forward until

the rear leveling leg is removed from the

bracket. Adjust the legs up or down

until range is level. Push range back

into position. Check that rear leveling

leg is engaged in bracket.

Note: Oven must be level for

satisfactory baking oonditions.

16

Connect ductwork to range. Check

that power supply cord is not interfering

with duct work.

A WARNING

Fire Hazard

Do Not make connection too tight.

The regulator is die cast.

Overtightening may crack the

regulator, resulting in a gas leak

and possible fire or expiosion.

Ail connections must be wrench-

tightened.

1/2" nipple ,,

...

,

1/2" close nipple

flexible connector

\ /

1/2" adapter 1/2" adapter

manual

shutoff valve

pressure regulator

1 7

.

Remove the storage drawer by lifting

slightly and pulling out of range.

Remove the regulator plug and

assemble the flexible connector from

the gas supply to the pressure regulator

in order: manual shutoff valve, 1/2"

nipple, 1/2" adapter, flexible connector,

1/2" adapter, and 1/2" close nipple.

1 8

.

Pipe-joint compound made for use with

NATURAL and L.P. gas must be used to

seal all gas connections. Check that

the shutoff valve is open between the

regulator and gas valves. If flexible

connectors are used, be certain

connectors are not kinked.

19.

Open shutoff valve in the gas supply

line. Wait a few minutes for gas to

move through the gas line.

A WARNING

Fire Hazard

Do Not use an open fiame to test for

ieaks from gas connections.

Checking for leaks with a flame may

result in a fire or explosion.

20

.

Use a brush and liquid detergent to test

all gas connections for leaks. Bubbles

around connections will indicate a leak.

If a leak appears, shut ott gas valve

controls and adjust connections. Then

check connections again,

NEVER TEST

FOR GAS LEAKS WITH A MATCH OR

OTHER FLAME. Clean all detergent

solution from range.

21

Turn fan to "HI" to check that venting

gasket for rear wall or floor venting

properly seals wall/floor duct plate to

wall/floor transition. If range does not

seal properly, contact a service

technician. Replace storage drawer,

22

.

Install grill and surface burner modules.

Note: If there is a cabinet on only one

side, the anti-tip bracket must be

installed against the cabinet.

Panel D