Assembly, Warning, Caution – Champion Power Equipment 92050 User Manual

Page 14: Add hydraulic oil, Add engine fuel

11

REV 92050-20131216

ENGLISH

92050

ASSEMBLy

6 . Start Engine . Extend and retract the wedge to purge

air from the hydraulic system . When the wedge

motion is smooth, the system is properly purged .

7 . Check the hydraulic oil tank sight glass . Add

approximately 1 to 1 .5 gallons of hydraulic oil to

bring the level back up to the sight glass .

Our engines work well with 10% or less ethanol blend

fuels . When using blended fuels there are some issues

worth noting:

– Ethanol-gasoline blends can absorb more water than

gasoline alone .

– These blends can eventually separate, leaving water

or a watery goo in the tank, fuel valve and carburetor .

– With gravity-fed fuel supplies, this compromised fuel

can be drawn into the carburetor and cause damage

to the engine and/or potential hazards .

– There are only a few suppliers of fuel stabilizer that

are formulated to work with ethanol blend fuels .

– Any damages or hazards caused by using improper

fuel, improperly stored fuel, and/or improperly

formulated stabilizers, are not covered by

manufacture’s warranty .

It is advisable to always shut off the fuel supply, run the

engine to fuel starvation and drain the tank when the

equipment is not in use for more than 30 days .

NOTE

DO NOT remove the hydraulic oil fill cap when the

engine is running or hot . Hot oil can escape causing

severe burns . Always allow the log splitter to cool

completely before removing the hydraulic oil cap .

High fluid pressure and temperatures are created

in the hydraulic log splitters . Hydraulic fluid will

escape through a pin-size hole opening and can

puncture skin and cause severe blood poisoning .

Inspect hydraulic system regularly for possible

leaks . Never check for leaks with your hand while

the system is pressurized . Seek medical attention

immediately if injured by escaping fluid .

WARNING

Add Hydraulic Oil

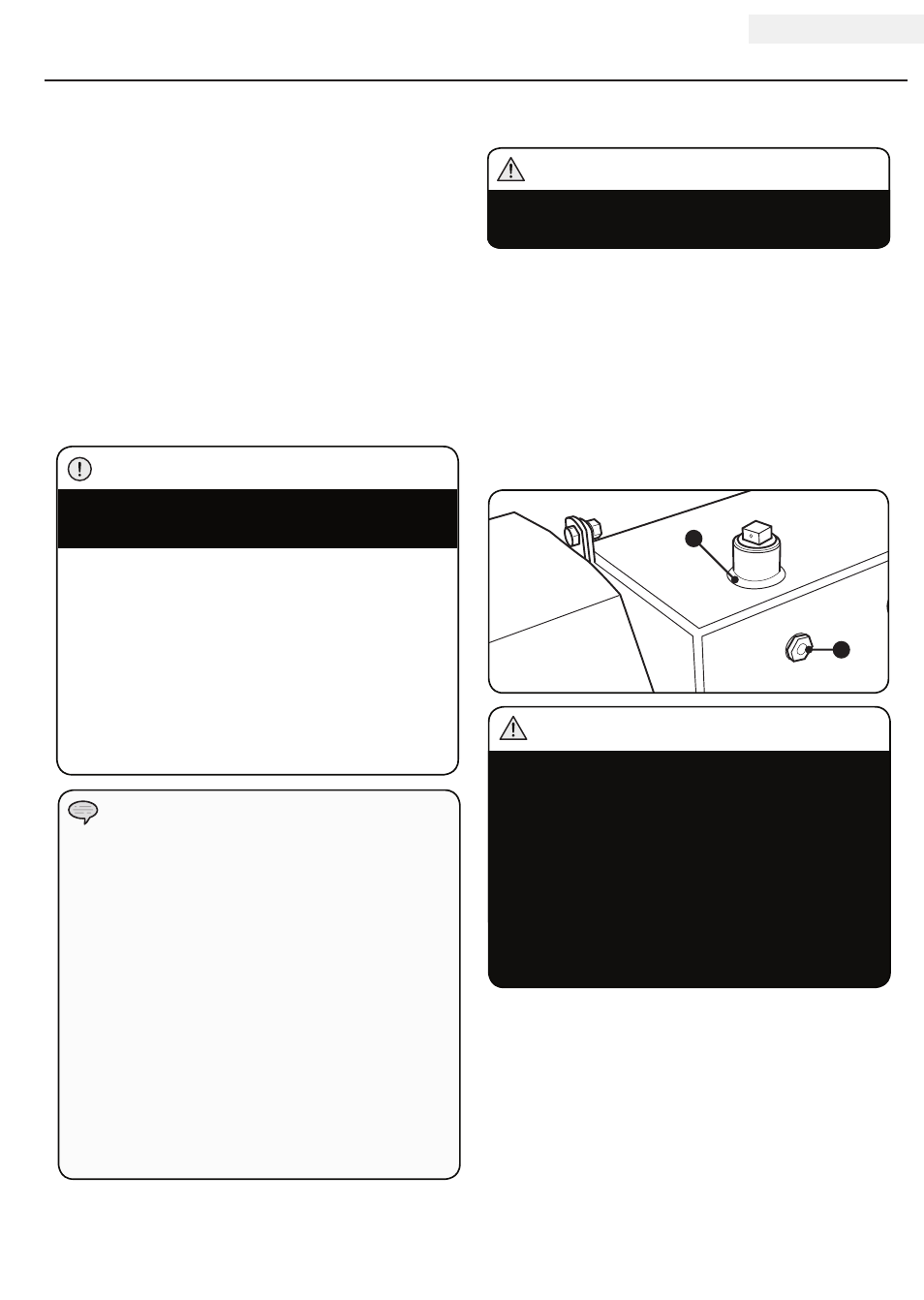

1 . Make sure the log splitter is on a flat, level surface .

2 . Remove the oil plug from the oil tank . (A)

3 . Add 15 .1 L (4 gal .) of hydraulic oil - 10W AW32, ASLE

H-150, or ISO 32 are all acceptable types of fluid .

4 . Check the hydraulic oil level using the oil sight glass .

Oil level should be centered on the glass sight . (B)

5 . Replace and tighten the oil plug and orient the vent

hole away from the operator zone .

A

B

Add Engine Fuel

1 . Use clean, fresh, regular unleaded fuel with a

minimum octane rating of 85 and an ethanol content

of less than 10% by volume .

2 . DO NOT mix oil with fuel .

3 . Clean the area around the fuel cap .

4 . Remove the fuel cap .

5 . Slowly add fuel to the tank . DO NOT OVERFILL . Fuel

can expand after filling . A minimum of 6 .4 mm (¼ in .)

of space left in the tank is required for fuel expansion,

more than 6 .4 mm (¼ in .) is recommended . Fuel can

be forced out of the tank as a result of expansion if it is

overfilled, and can affect the stable running condition of

the product . When filling the tank, it is recommended

to leave enough space for the fuel to expand .

6 . Screw on the fuel cap and wipe away any spilled fuel .

Use regular unleaded gasoline with a minimum

octane rating of 85 .

Do not mix oil and gasoline .

Fill tank to approximately 6 .4 mm (¼ in .) below the

top of the tank to allow for fuel expansion .

DO NOT pump gas directly into the engine at the

gas station . Use an approved container to transfer

the fuel to the generator .

DO NOT fill fuel tank indoors .

DO NOT fill fuel tank when the engine is running or hot .

DO NOT overfill the fuel tank .

DO NOT light cigarettes or smoke when filling the

fuel tank .

CAUTION

Pouring fuel too fast through the fuel screen may

result in blow back of fuel at the operator while filling .

WARNING

Add Engine Fuel Cont’d.