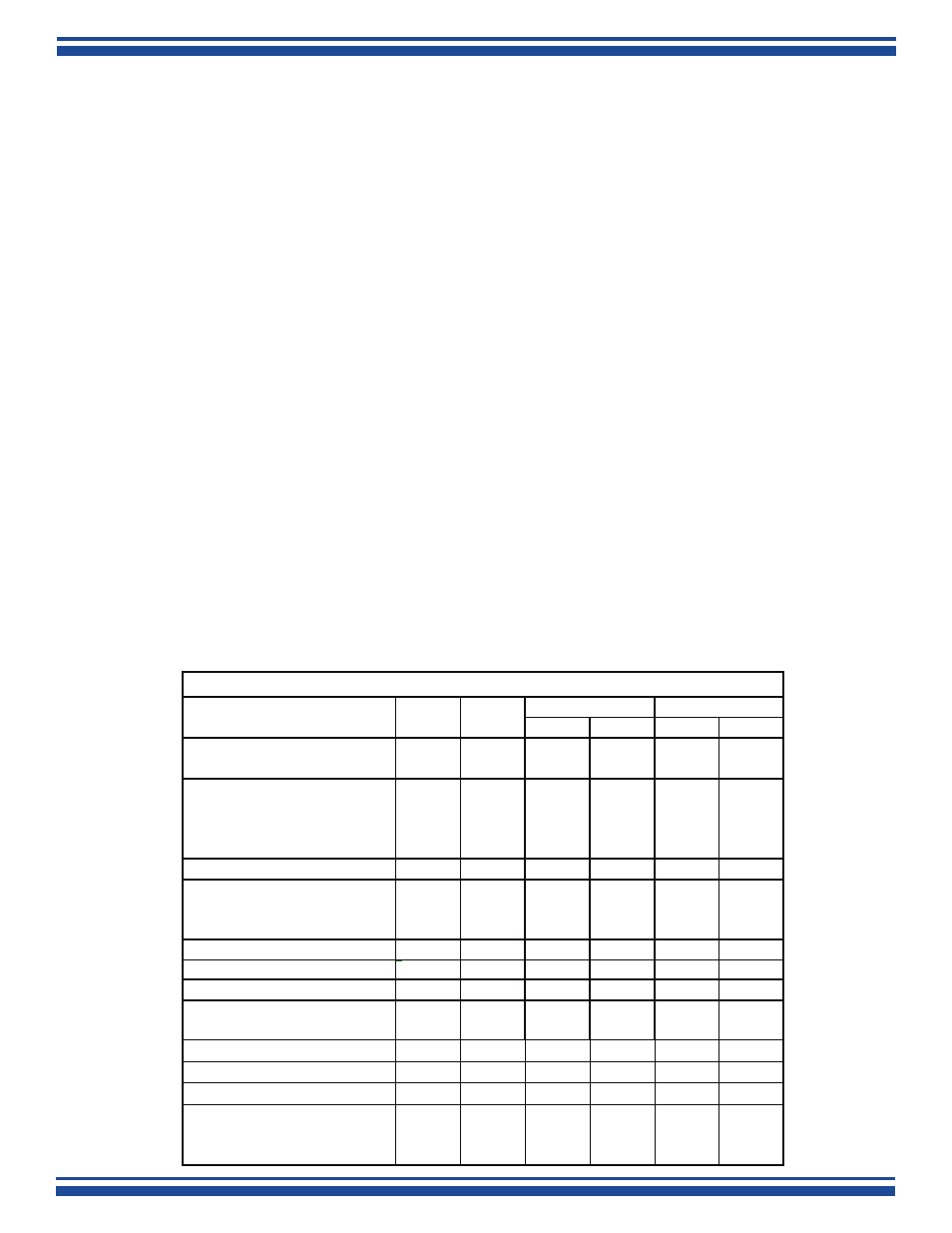

Battery terminal torque requirements, Table 1 – C&D Technologies 41-6965 Condensed User Manual

Page 4

The following maintenance schedule should

be followed:

Quarterly

•

Check pilot units temperature at the

negative terminal.

•

Measure and record the system float

charging voltage.

•

Measure and record the individual units float

charging voltage.

Semi Annually

•

Repeat the quarterly checks.

•

Optionally perform a 10 second high rate

(e.g. 100 ampere) load test on the individual

units.

•

Optionally perform an impedance or

conductance test for the purpose of trending

battery over time.

Annually

•

Repeat the semi annual checks.

•

Retorque all inter unit connecting hardware per

table 1.

•

Perform inter unit connector resistance

checks.

IX. PERFORMANCE TESTS

The battery system should be given a capacity

discharge test at acceptance when new and

biannually thereafter. When the capacity declines

to 85% of rating the battery should be capacity

tested annually.

The load current used for the capacity test should be

derated for testing temperatures below 75ºF.

41-6965/0512/CD 4 www.cdtechno.com

in.-lb.

N-m

in.-lb.

N-m

UPS12-100MR, UPS12-150MR,

UPS12-210MR

#10-32

3/8"

40

4.5

32

3.5

UPS12-300MR, UPS12-350MR,

UPS12-400MR, UPS12-490MR,

UPS12-490MRLP, UPS12-540MR,

UPS12-620MR

1/4-20

7/16"

110

12.4

110

12.4

TEL12-30, TEL12-45

#10-32

3/8"

40

4.5

32

3.5

TEL12-70, TEL12-80, TEL12-90,

TEL12-105FS, TEL12-125,

TEL6-180

1/4-20

7/16"

110

12.4

110

12.4

DCS-33IT, DCS-50IT

#10-32

3/8"

40

4.5

32

3.5

DCS-75IT, DCS-88HIT, DCS-100HIT 1/4-20

7/16"

110

12.4

110

12.4

BBG-85

#10-32

3/8"

40

4.5

32

3.5

BBG-165RT, BBG-180RT,

BBG-210RT

1/4-20

7/16"

110

12.4

110

12.4

Battery Terminal Torque Requirements

Initial Torque

Annual Retorque

Bolt Size Wrench

Size

Battery

SGC12-30, SGC12-45

#10-32

3/8"

40

4.5

32

3.5

SGC12-70, SGC12-80, SGC12-90,

SGC12-105FS, SGC12-125,

SGC6-180

1/4-20

7/16"

110

12.4

110

12.4

VRS-33IT, VRS-50IT

#10-32

3/8"

40

4.5

32

3.5

VRS-75IT, VRS-88HIT, VRS-100HIT 1/4-20

7/16"

110

12.4

110

12.4

TABLE 1