Maintenance, When to hone, Sharpening the blade – Bullet Tools 613 User Manual

Page 7: Adjusting the blade, Beveled side flat side

7

MAINTENANCE

WHEN TO HONE

There are three situations when it is very important

to hone the blade (remove burrs) on the flat side of

the blade.

1. After the first 30-100 cuts on a new blade

2. Every 100+ cuts on the job

3. When the blade has been re-sharpened

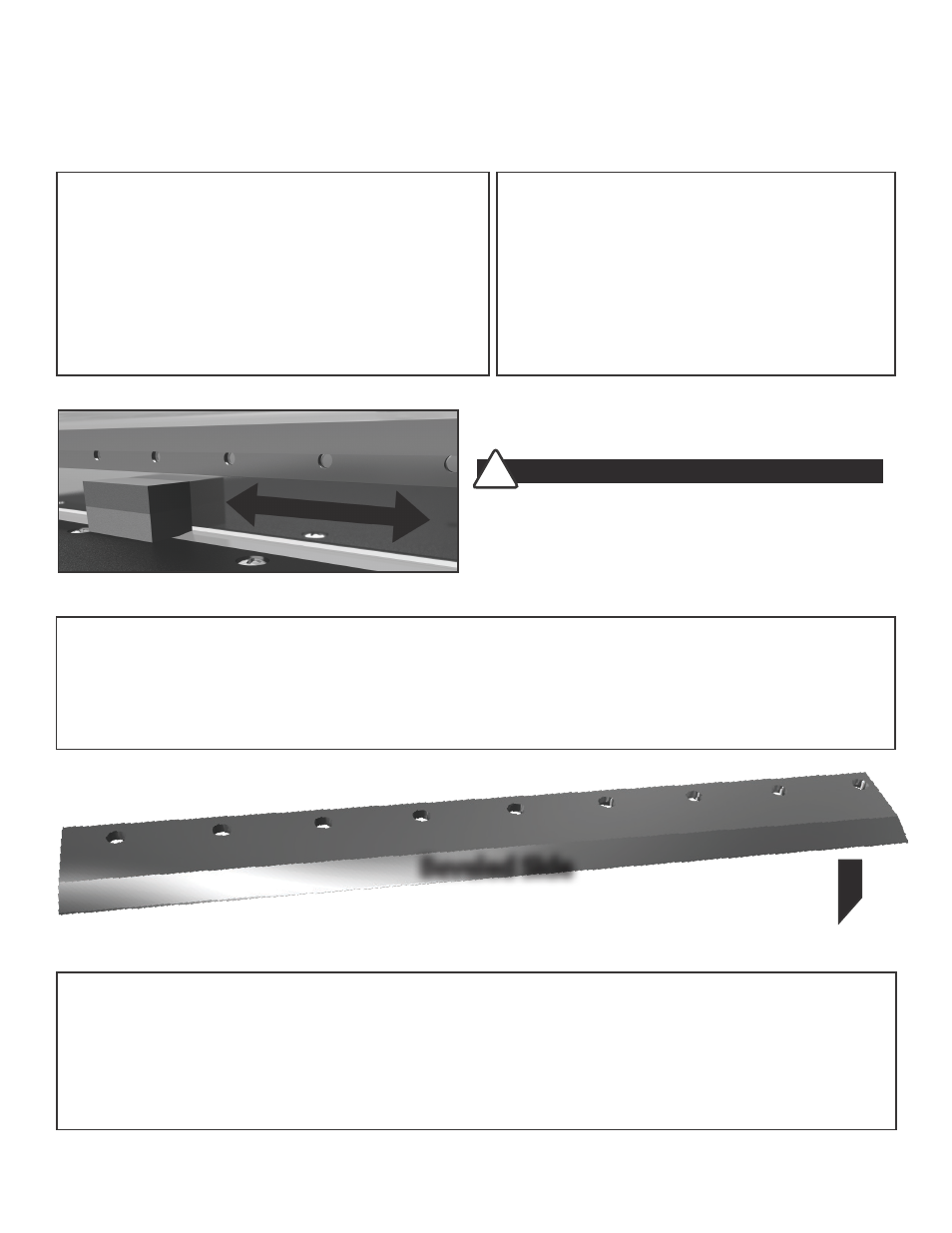

SHARPENING THE BLADE

The blade can be sharpened to restore a one-side, 21º - 22º knife edge. It is important to note that the

blade must be sharpened only on the beveled side, leaving the flat side flat.

We recommend that power grinding only be done professionally, as the blade must be fluid cooled during this process.

ADJUSTING THE BLADE

Your Magnum™ Siding Shear is equipped with adjustment "jack" screws (see pic on next page) for fine

tuning the angle of your blade or compensating for small blades (Blades shrink every time they are

re-sharpened). To tilt your blade, turn the machine upside down as when removing the blade - loosen

(but don't remove) the Item D screws. Adjust the jack screws to desired position with 5/32" or 4mm

Allen wrench.

TO HONE

With the blade in the machine, it is quick and

easy to hone; Simply pull the Magnum™ Siding

Shear handle down until the blade is just above

the blade stop (approximately 1/8"). Then, lay

the wide flat side of the hone stone against the

flat side of the blade and move hone stone from

end to end 2 to 3 times to remove any burrs.

Use Hand Protection! Blade is very sharp!

Note: It is not necessary to remove the small nicks or chips from

the blade edge when sharpening or honing.

!

Beveled Side

Flat Side

(Table Side)