Technical specifications, Maintenance and service, 1 cleaning – Boekel Scientific 260010-2 MicroCooler II User Manual

Page 7

6

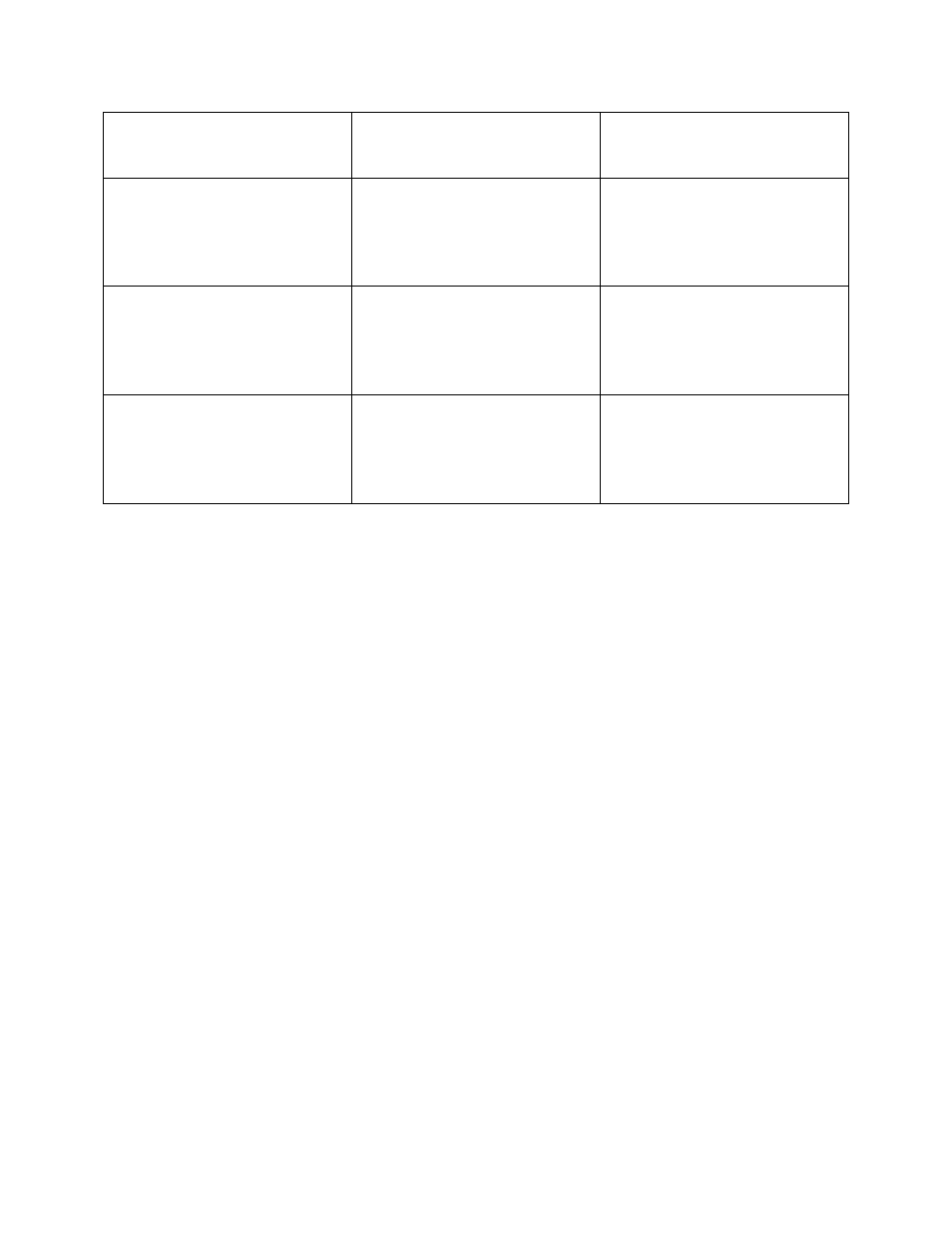

b. Temperature control

circuit fault

b. Have unit checked by

competent person

3. Well temperature continues

to rise when not expected

a. Actual temperature is

lower than set temperature

b. Temperature control

circuit fault

a. Check set temperature

b. Have unit checked by

competent person

4. Well temperature does not

cool when expected to

a. Actual temperature is

lower than set temperature

b. Temperature control

circuit fault

a. Check set temperature

b. Have unit checked by

competent person

5. Well temperature continues

to cool when not expected

a. Actual temperature is

higher than set

temperature

b. Temperature control

circuit fault

a. Check set temperature

b. Have unit checked by

competent person

7. Technical Specifications

This equipment is intended for indoor use and will meet its performance figures within

the ambient temperature range of 10

°C to 35°C, with maximum relative humidity of 80%

(non-condensing). Installation Category II (transient voltages). Pollution Degree 2 in

accordance with IEC 664. Suitable for operation at altitudes of up to 6500 feet.

Specifications:

Temperature Range:

ambient to 18

°C below ambient,

typically 4

°C

Supply Voltage Range:

115V +/- 10%, 50/60 Hz

230V +/- 10%, 50/60 Hz

Power Rating:

Model 260010: 75W

Model 260010-2: 75W

8. Maintenance and Service

All Boekel laboratory products are designed to comply with IEC1010-1. No routine

maintenance is required.

8.1

Cleaning

Disengage power cord prior to cleaning. The outer casing may be cleaned with water and

a damp cloth. Do not submerge or immerse the MicroCooler II in water. Abrasive

materials such as paper towels may scratch the well cover or the plastic body. Do not use

solvents to clean the well cover or the plastic body. Before using any cleaning or

decontamination method, users should check that the proposed method would not damage

the equipment.