Maintenance – AquaCraft Miss Vegas Deuce User Manual

Page 11

11

MAINTENANCE

When you are through operating your boat for the day, be

sure to perform these basic maintenance procedures. This

will prolong the life of the Miss Vegas Deuce and help to

ensure trouble-free running.

ENGINE MAINTENANCE

Drain the tank of any remaining fuel. Add some after-run oil

to the engine to protect the internal parts. We recommend

removing the glow plug, opening the carburetor all the way,

and placing 10–12 drops of after-run oil down the barrel of the

carburetor. Place a rag over the glow plug hole and turn the

engine over with the starter. Repeat this step at least one more

time to make sure the inside of the engine is fully coated.

HULL MAINTENANCE

Remove the hatch cover. Open the radio box. Soak up any

excess water with a paper towel. Remove the driveshaft and

wipe away as much grease as you can. Spray the driveshaft

down with WD-40 and place it in a plastic bag until you

are ready to operate the boat again (See the Driveshaft

Maintenance section below). Wipe down the entire boat

with spray-on cleaner and a paper towel.

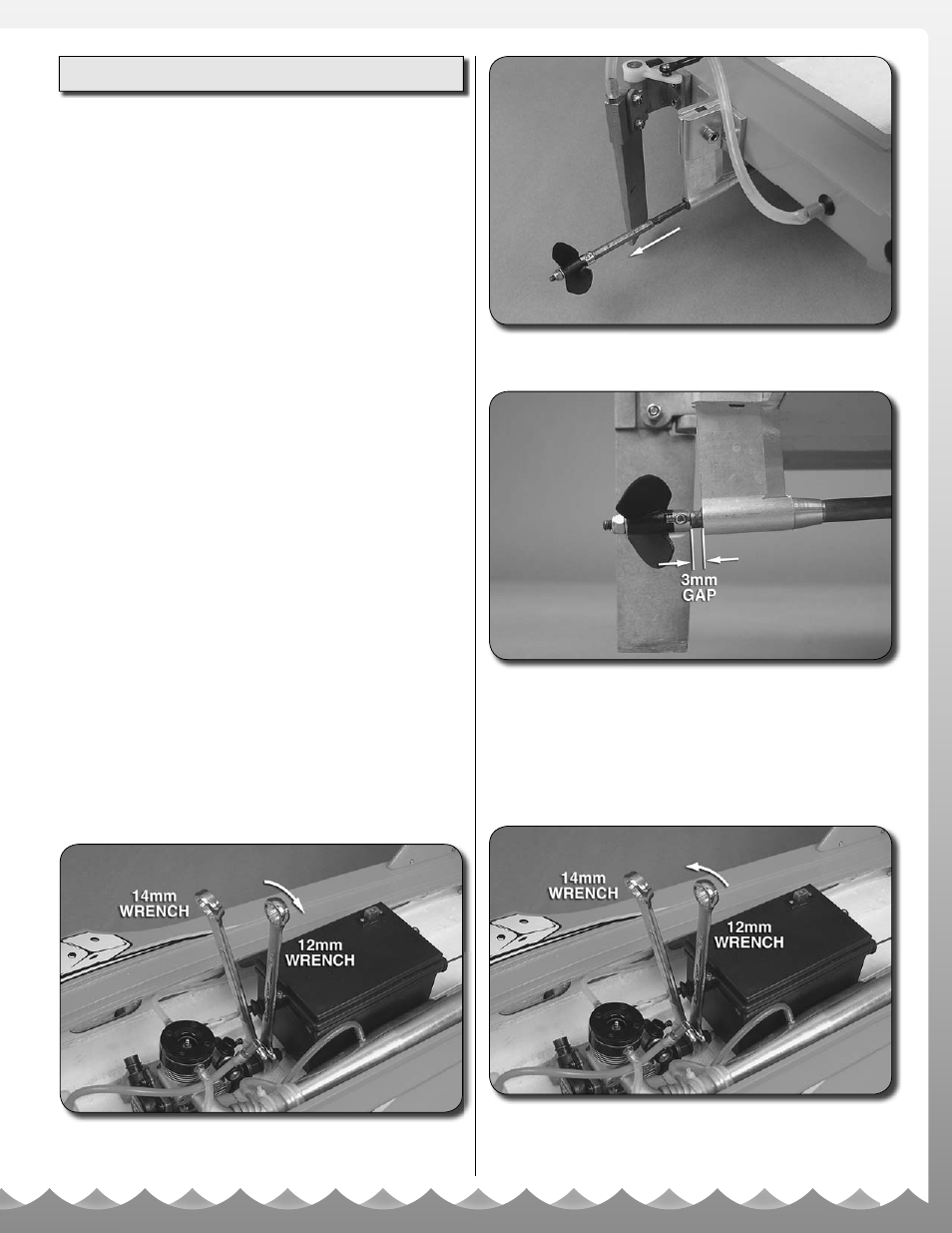

DRIVESHAFT MAINTENANCE

IT IS CRUCIAL that you remove the fl exible driveshaft and

lubricate it with AquaCraft Speed Grease cable lubricant

(AQUB9500) or some type of heavy-duty marine grade

cable grease at the beginning of each daily session and

again every 2-3 tanks. This exercise will require a 12mm and

14mm wrench.

1. Remove the canopy.

2. Use the 14mm wrench to hold the fl ywheel nut in place

while loosening the collet assembly with the 12mm wrench

as shown.

3. Gently pull the driveshaft out and wipe off any old grease.

4. Apply AquaCraft Speed Grease cable lubricant

(AQUB9500) or heavy-duty marine grade cable grease to

the driveshaft and reinsert it into the stuffi ng box. Slowly

rotate the driveshaft while gently pushing it back into place.

Be sure to leave about a 3mm [1/8"] gap minimum between

the drive dog and the stuffi ng box as shown.

5. Use the 14mm wrench to hold the fl ywheel steady while

tightening the collet assembly with the 12mm wrench as

shown. Make sure there is still a 3mm [1/8"] gap between

the drive dog and the stuffi ng box.