AAF International ArrestAll User Manual

Page 2

2

1.2 Foundations

The foundation must be level and adequate to support the collector ’s

operating weight including dust load, discharge devices, wind load if

applicable, plus any auxiliary equipment if applicable.

1.3 Space Requirements

Unit location will be determined by system design, space availability,

and access requirements. Access to the front of the unit is necessary

for dust removal and cartridge replacement. Top access is required

for motor, fan, and ancillary component service. Side access is

required for shaker motor and control access.

Explosion vents, if furnished, are located on the side opposite the

access door. It is recommended that the vent(s) be ducted outside

and away from any area containing personnel or equipment. Duct

flanges can be match drilled to the collector housing wall, but they

must be supported separately from the unit.

1.4 Handling

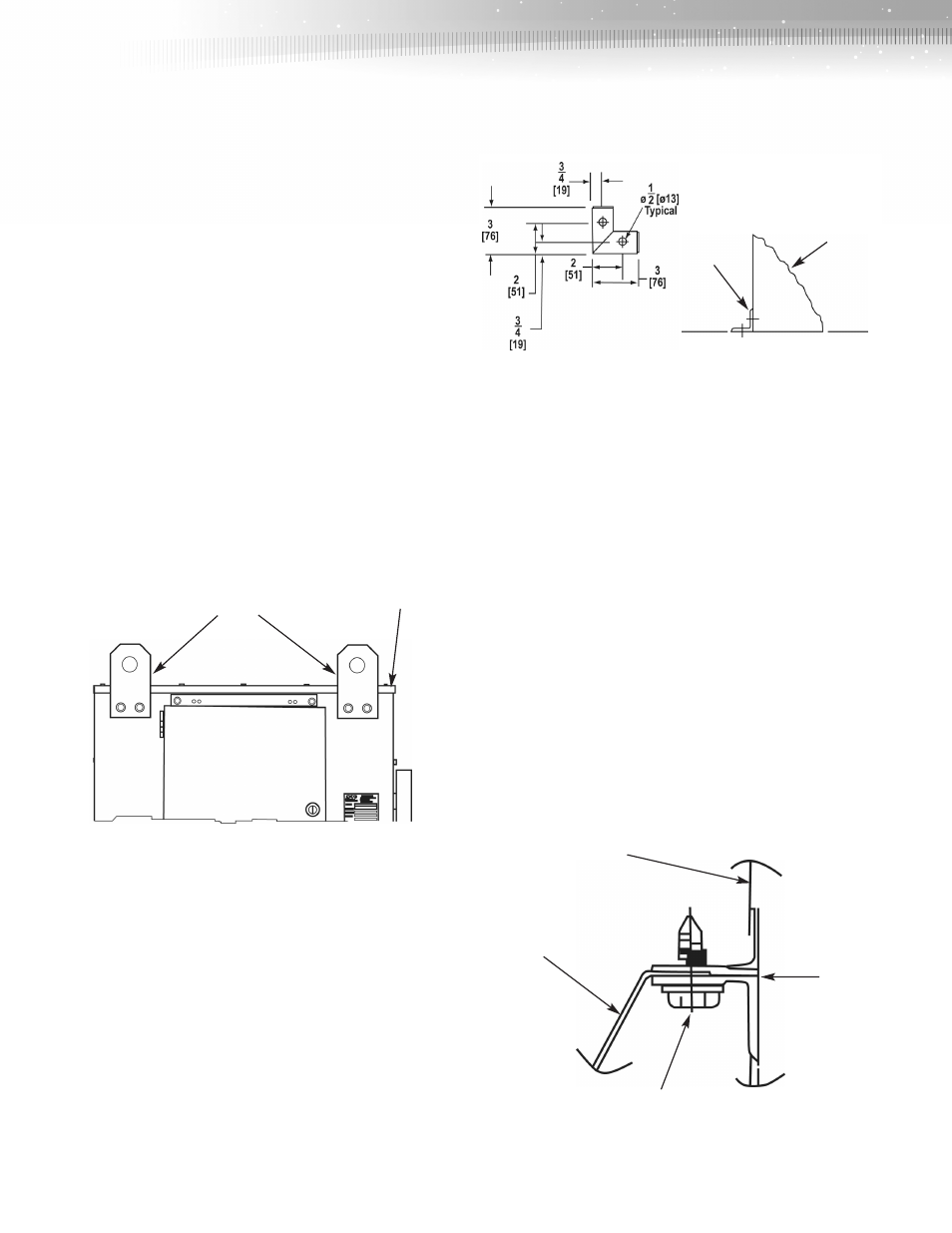

All units are shipped in an upright position. Lifting lugs are provided

on the cartridge section as well as the fan for ease of handling

(Figure 1). Spreader bars should be used on the housing. Fork truck

handling should be sufficient for the funnel section. Shipping weights

are listed in the table in Section 8.0.

2.0 Installation

The AR ArrestAll dust collector is not designed to support inlet and/or

outlet ductwork. The duct(s) should be connected to the collector with

flexible connections to eliminate vibration transmission.

Close coupling a duct elbow to the collector inlet may result in an

uneven velocity profile. This condition could cause previously

collected material to be re-entrained. Three to four duct diameters

of straight run will give an even airflow distribution at the inlet.

2.1 Anchoring

The AR ArrestAll collector is designed for installation on a

flat surface. Units must be suitably anchored. Anchor holes are

provided at the base of the support legs on the funnel bottom units

(Figure 2), and anchor clips are provided on the cart bottom

(Figure 3). Flat bottom units can be installed by drilling holes in the

bottom of the units. Holes drilled in the flat bottom base should be

gasketed or caulked to prevent air bypass.

Inlet Transitions

Standard accessories, such as the inlet transition (AR1 only), are

shipped loose for field installation with the caulk and attachment

hardware provided.

2.2 Field Assembly of Major Components

Funnel Bottom Units

Self-tapping screws and caulk are provided for installation of the

funnel bottom section to the cartridge section (Figure 4). Assemblies

can be bolted-up from the outside of the unit; interior access is not

required. See the field installation drawing for additional detail. The

fan is bolted to the top of the unit using the provided hardware. Fan

discharge orientation can be varied to suit owner ’s requirements.

See the fan installation drawing for additional detail.

Housing

Clips

Figure 3. Anchoring—Cart Bottom

Lifting Lugs

Typ (4) Places

Figure 1. Lifting Lugs

Top

Back

Front

Figure 2. Anchoring—Funnel Bottom

Cartridge

Section

Figure 4.

Caulk

Funnel

Section

Self Tappers