0 installation – AAF International Type W RotoClone User Manual

Page 3

2.0 Installation

The following instructions should be read carefully before installing

the RotoClone.

2.1 Foundations

Foundations must be true, level, and rigid enough to prevent vibration

and support the weight of the RotoClone. (See Section 6, Table 2 for

net weights of RotoClone.)

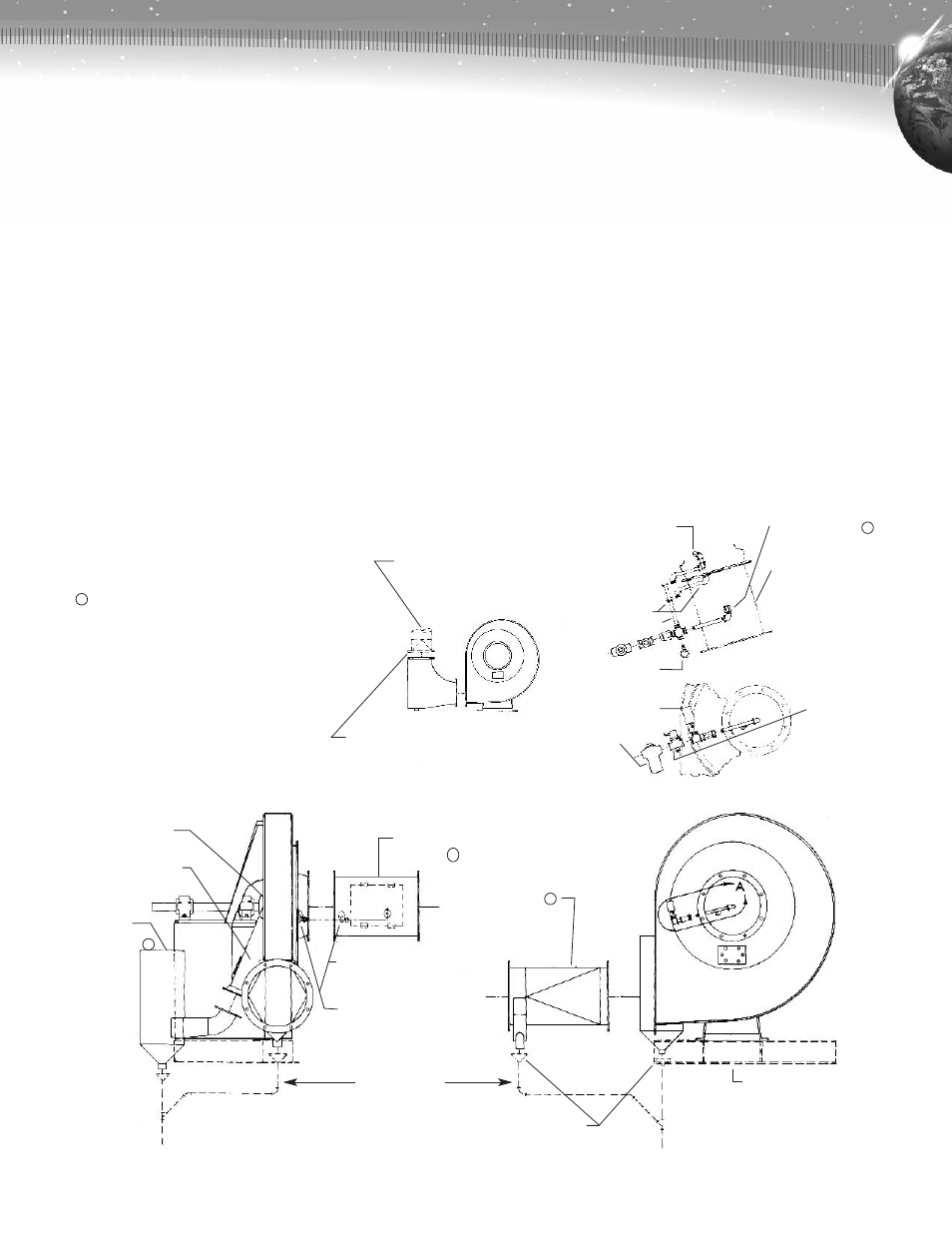

2.2 RotoClone Erection (Arrangement A)

Refer to Installation Diagram - Figure 1. Assembly of the RotoClone

should proceed in the following manner sealing all joints using

gaskets and bolts included with shipment. Some RotoClones,

size 16 and smaller, have inlet, outlet, and expansion chamber

welded to housing in lieu of flanged and bolted connections.

1. Bolt RotoClone outlet connection to RotoClone outlet. Be sure

that the bottom of the outlet piece is even with the bottom of the

RotoClone outlet and that no gasket material is protruding inside

as this will cause water carryover.

2. Bolt RotoClone on foundation. If vibration isolators are used,

a sub-base must be used to support the exhauster with the

isolators located at each corner of the sub-base. Connecting

ductwork requires flexible connections when vibration isolators

are used.

3. Bolt RotoClone inlet connection to RotoClone inlet.

(Note: Eliminate elbows and other inlet obstructions if at all

possible. Sharp elbows at the fan inlet or other disturbances

will seriously reduce the air volume and can affect the RotoClone’s

dust collection efficiency. A minimum of 4-5 inlet diameters of

straight duct prior to the RotoClone is recommended to evenly

distribute airflow.)

4. Bolt expansion chamber to water outlet.

Discharge stack supplied by others.

Extend vertically above roof line.

Joints must be made water-tight.

Supply gasket at RotoClone connection.

90˚ Elbow Assembly Shown

Auxiliary Spray Nozzle

Location for

sizes 8 - 14

*

Pressure Gage

*

Inlet Spray Nozzle

*

Inlet Connection Assembly

Pressure Switch

*

Strainer

*

Solenoid Valve

(if supplied)

*

View A

These parts and necessary connecting

bolts are shipped separately on sizes

24 and larger or for units with special

interior coatings. On standard units

sizes 16 and smaller, these pieces

may be welded to housing.

These parts are shipped separately.

*

*

Shaft Seal

Water Outlet

*

Expansion

Chamber

Side Elevation

Front Elevation

Inlet Connection

Assembly

Location for

sizes 8 - 14

To auxiliary spray nozzle

*

Piping by others

Outlet Connection

Assembly

*

Open Drain Funnel

Foundation by others

Figure 1 — Installation Diagram

3