AAF International PRU User Manual

Page 19

19

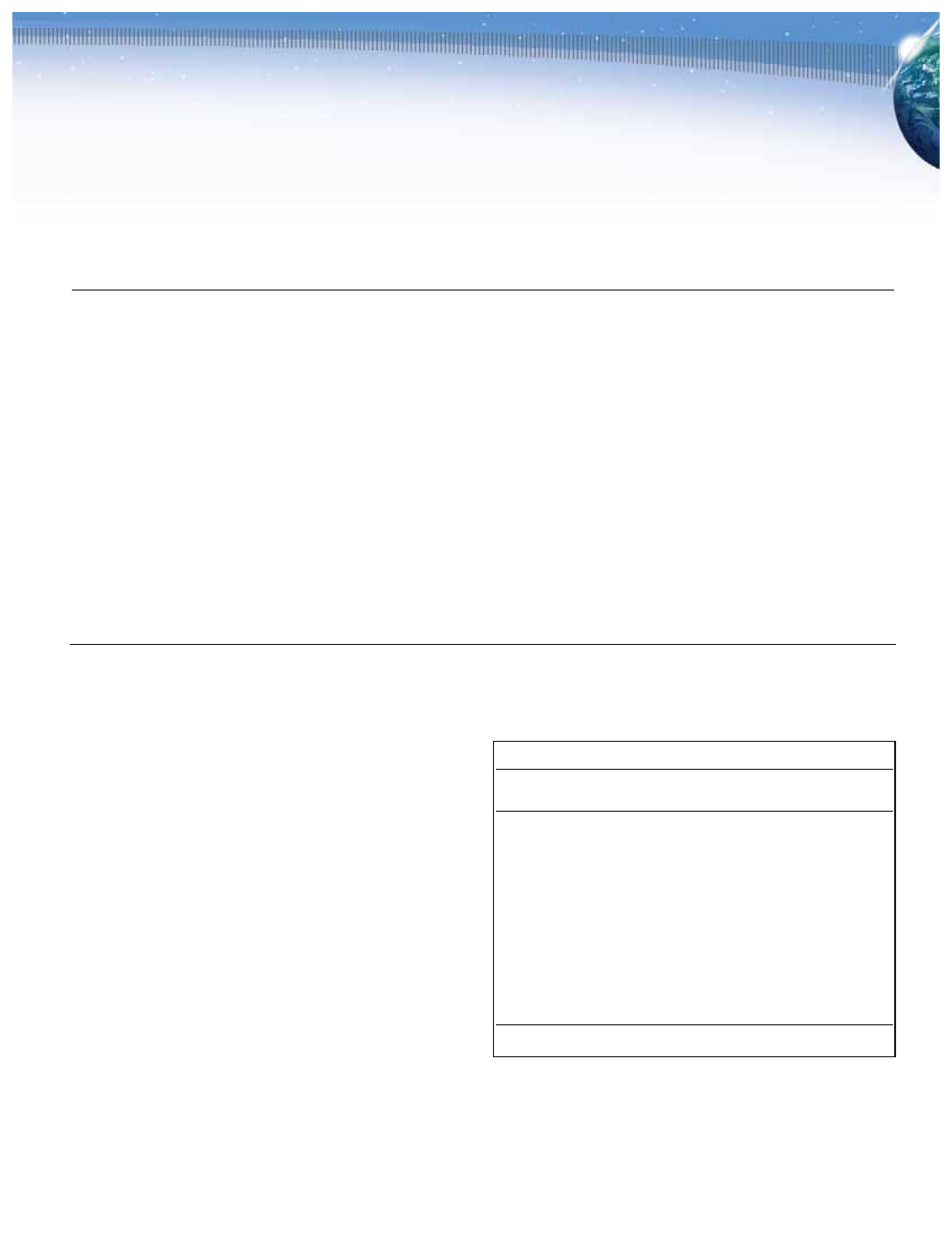

7.0 Spare Parts List

It is recommended that the following spare parts be stored at the installation site for routine maintenance purposes. The quantities required will

depend on the size of the system. Consult with your AAF representative to determine actual quantities required. Minimum recommended

quantities are provided in the table below.

AAF Part Number

Description

Recommended Spares

Refer to the original customer purchase

SAAF cassette gas-phase chemical filters

One full replacement set of each type

order and the AAF submittal drawing

included in the system

Refer to the original customer purchase

Particulate filters

One full replacement set of each type

order and the AAF submittal drawing

included in the system

2500932

Extruded plastic strips which provide

20% of the number supplied

low friction cassette bearing surface

with the equipment

2500924

Hollow core track gasket

One full replacement set or a roll of 50 feet

2500981

Access door perimeter gasket

One full replacement set or a roll of 50 feet

2500999

Access door side seal gasket

One full replacement set

Refer to the original customer purchase

Fan

One replacement fan

order and the AAF submittal drawing

To order replacement parts call: 1-800-477-1214.

8.0 Equipment Characteristics, Dimensions, Operating

Weights, and Shipping Weights

See the AAF submittal drawing supplied on the specific order.

9.0 Technical Guidelines

9.1 Fan Selection and Sizing: The following guidelines are provided

to inform the user of the criteria used by AAF to select an integral fan

that is provided with the RU.

9.1.1 Determination of Fan Selection Pressure Drop: The

following concerns initial and final filter pressure drop and the use

of pressure drop for fan selection. AAF’s standard product literature

indicates the start-up, being the clean filter or initial, and the

recommended final, or dirty filter, pressure drops for all filters at a

particular airflow velocity. If the airflow velocity in the actual

installation differs from that referenced in the literature, then the

start-up (initial) pressure drop will also differ. For instance, an AAF

PerfectPleat or M-Pak filter is typically rated at 500 FPM velocity.

However, when used with a type HD cassette, the airflow velocity

will normally be 250 FPM so the initial pressure drop will be lower.

Similarly, the final pressure drop referenced in the literature is a

“recommended” value only, and the filter may be changed out at a

lower pressure drop, if required.

Table 3: Nominal Pressure Drop (ΔP) @ 250 FPM Nominal Airflow Velocity

Pressure Component

Initial ΔP (in. w.g.)

Final ΔP (in. w.g.),

Recommended or Actual

External pressure

0.10

0.10

loss from inlet and

outlet ducts

2” PerfectPleat

0.11

1.0

HD Cassette with

0.73

0.73

SAAFOxidant

HD Cassette with

0.73

0.73

SAAFOxidant

After-filter

0

0

M-Pak filter

0.23

1.5

TOTALS

1.90

4.06

A typical pressure drop profile for an RU might be as shown in

Table 3 below: