6 | maintenance – GEA Bock FK30 User Manual

Page 18

18

D

GB

F

I

09705-09.2013-DGbFIT

r

FK30 / ...

235 N

235 TK

275 N

275 TK

325 N

325 TK

235 K

275 K

325 K

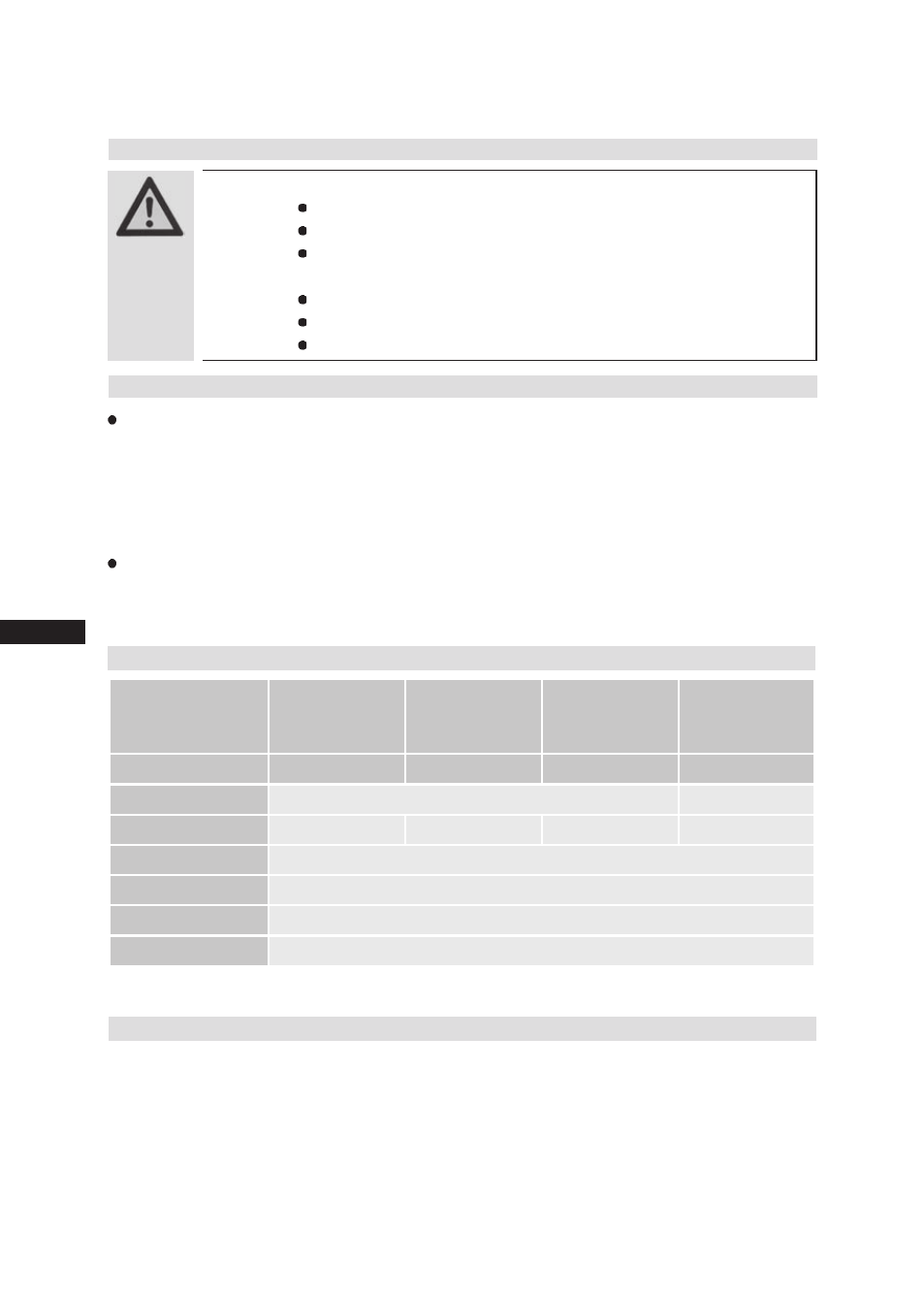

Designation

Art.-No.

Art.-No.

Art.-No.

Art.-No.

Set of gaskets

80232

80126

Valve plate kit

80240

80242

80241

80010

Set of shaft seals

80123

Oil collector ring

80127

Oil SP 46, 1 Ltr.

02279

Oil SE 55, 1 Ltr.

02282

Oil change: In principle, an oil change is not mandatory if the system is correctly manufactured

and operated. However, based on decades of experience we recommend that the following oil

change/service work is carried out:

-

First oil change during the first maintenance of the vehicle.

-

Then after every 5,000 operating hours, though no more than 3 years, clean the oil strainer

at the same time. If necessary, also empty the oil reservoir at the shaft seal.

Annual checks: Oil level, tightness of the compressor, running noise, pressures, temperatures,

function of the auxiliary equipment check.

The valve is maintenance free.

However, constant leakage can occur after blowing off due to abnormal operating conditions. This

leads to reduced performance and increases the compressed gas temperature. In this case check the

valve and replace as necessary.

6.4 Integrated decompression valve (only FK30/275 + 325)

Only use genuine Bock spare parts!

6.3 Recommended spare parts

6.1 Preparation

6.2 Work to be carried out

6| Maintenance

WARNING! Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.