Big country 4 x 2 – Cub Cadet 4 x 2 Big Country - Steel Bed User Manual

Page 9

Big Country 4 x 2

5

NOTE: If the friction material is contaminated

with oil, identify the source, repair the leak, and

replace the shoes.

NOTE: The friction material on the brake

shoes should not be worn to a thickness of less

than 3/32”. The friction material should not be

contaminated with oil. The friction material

should not show any signs of separating from

the steel portion of the brake shoe. If any of

these conditions exist, replace the brake shoes.

NOTE: If drums are reused at the time of reline,

they should be turned if the depth of scoring

exceeds .010"; if the inside diameter at the open

end of the drum exceeds the inside diameter at

the closed end by more than .010: (bellmouth

condition); if the drum rubbing surface is con-

cave or convex by more than .005"; if they are

heat checked; and if they are out of round by

more than .010 total indicator reading or if pedal

pulsations or brake roughness is noticed. The

rebore limit is .060" over the original maximum

drum diameter of 7.005". If reboring to .060”

maximum does not correct any of these condi-

tions, then the drum should be replaced. New

drums have a #50 grit blast applied to the rub-

bing surface. Drum surface finish is 40-125

micro-inches friction surface of the drum should

be smooth and true within .003 “.

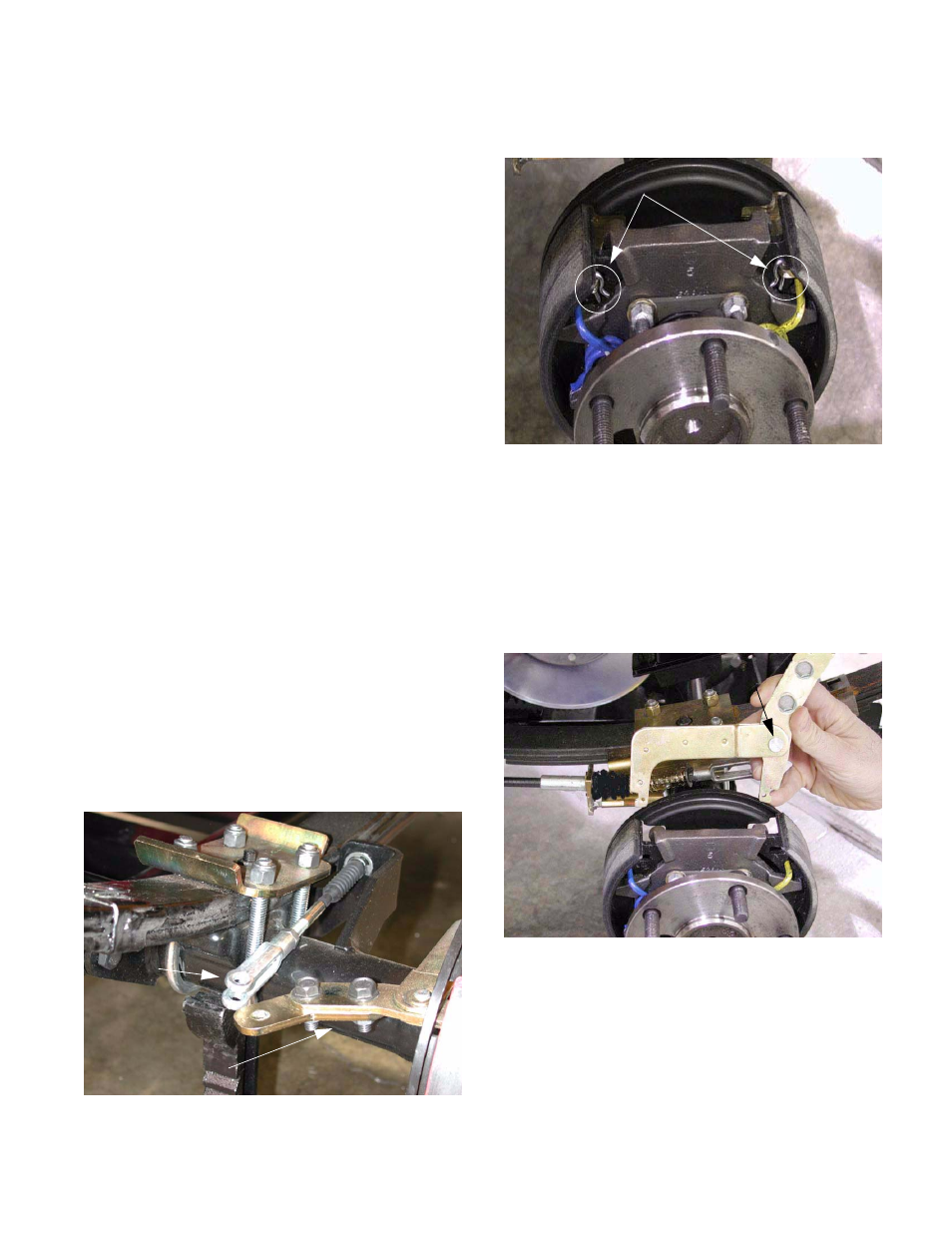

3.17. Remove the cotter pins and clevis pins securing

the brake cables to the actuators on each brake.

The brake pedal may be carefully depressed

while the cable is disconnected from the actua-

tor. This will confirm that the cable and linkage

move without binding. See Figure 3.17.

Figure 3.17

Clevis

Brake Actuator

3.18. Remove the “R” shaped clips securing the brake

actuator to the brake shoes. See Figure 3.18.

3.19. Remove the brake actuator.

NOTE: The clevis pin is installed in the hole fur-

thest from the pivot pin. The head of the pivot is

facing. The Pivot pin is secured to the actuator

by a C-clip and wave washer.

3.20. Inspect the actuator for any binding at the pivot

3.21. Rotate the star wheel on the adjuster to shorten

the adjuster to the end of its travel.

Figure 3.18

“R” Shaped clips

Figure 3.20

Check for binding

and wear