Checking transaxle oil, Changing transaxle oil, Drive belt – Cub Cadet 642 User Manual

Page 15

15

Checking Transaxle Oil

IMPORTANT:

Hot hydraulic oil will expand and show

incorrect oil level. Check oil level when oil is cold and

with engine is not running.

•

Park vehicle on level surface and apply parking

brake.

•

Allow transmission sufficient time to cool before

attempting any maintenance or repairs.

•

Raise and secure cargo box, if manual lift.

IMPORTANT:

Dirt and debris in oil may cause damage to

transaxle. Clean area around opening before removing

dipstick.

•

Remove dipstick located on the top of the transaxle

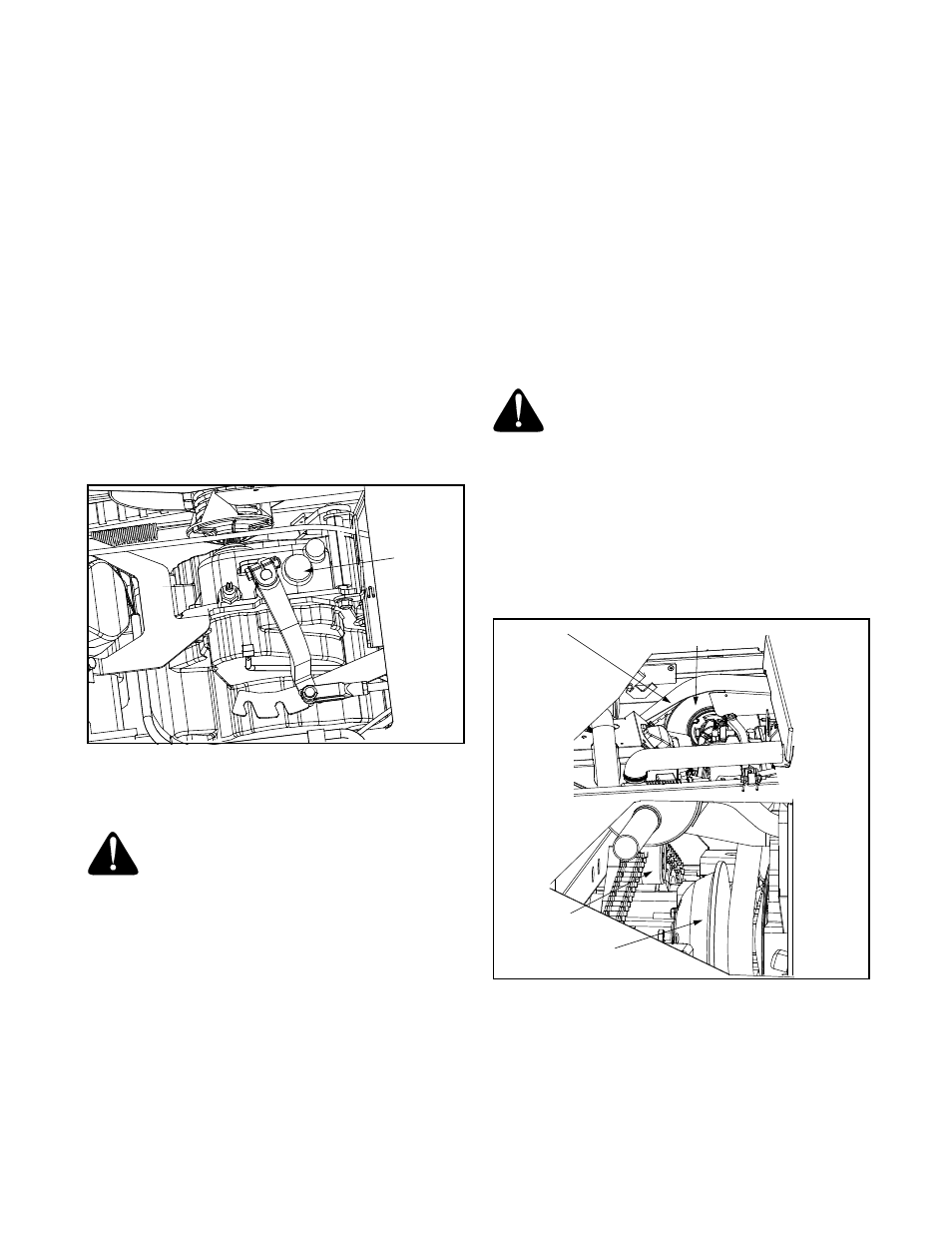

housing and wipe dipstick clean. See Figure 18.

•

Check oil level by screwing dipstick fully into

transaxle case and then remove to check oil level.

•

Add universal (Hydraulic) tractor transmission fluid

as needed until oil level reaches the full mark on

dipstick.

•

Install and tighten dipstick.

•

Lower cargo box.

Figure 18

Changing Transaxle Oil

WARNING: The fluid for your transmission

has been specially formulated to ensure the

safe and proper operation of your vehicle.

When changing the transmission fluid replace

it with Cub Cadet Drive System Fluid Plus

ONLY. Failure to use Cub Cadet Drive

System Fluid Plus may result in a failure of the

drive system which could result in property

damage or personal injury. Do not substitute.

IMPORTANT:

If brakes start to chatter or are noisy when

applied, change transaxle oil before waiting until the

service interval.

•

Park vehicle on level surface and apply parking

brake.

•

Raise and secure cargo box, if manual lift.

•

Access drain plug through slot on underside of

machine and remove plug.

•

Check O-ring on drain plug and replace if missing

or in poor condition.

•

Install and tighten drain plug.

IMPORTANT:

Dirt and debris in oil may cause damage to

transaxle. Clean area around opening before removing

dipstick.

•

Remove dipstick located on top of transaxle

housing and wipe dipstick clean.

•

Add approximately 189 oz (5.5 liters) of Shell TTF-

SB Oil (Cub Cadet Part No. 737-3120 or 737-3121).

•

Check oil level by screwing dipstick fully into

transaxle and then remove to check level.

•

Wait for two minutes and then check oil level again.

•

Install dipstick and lower cargo box.

Drive Belt

WARNING: Fingers or loose clothing can get

caught in rotating parts. Stop engine and wait

for all moving parts to stop before servicing.

•

Park vehicle on level surface and apply parking

brake.

•

Raise and secure cargo box, if manual lift.

•

Rotate and inspect belt for wear or damage.

•

Measure width of belt on top surface. The width

should be a minimum of 1.1 (27 mm).

•

Replace belt if worn beyond limit.

To replace belt:

•

Remove hardware and belt shield. See Figure 19.

Figure 19

•

Route belt over drive clutch pulley (front pulley).

•

Route belt from drive pulley (rear pulley).

See Figure 19.

•

Install new belt by routing over drive pulley (rear

pulley) and then over the drive clutch pulley (front

pulley). Install belt shield.

Dipstick

Belt Shield

Clutch Pulley

(Front)

Drive Pulley

Chain Adjuster

(Rear)