Getting started in soft solids testing, The constant rate test, Brookfield – Brookfield R/S-SST Rheometer User Manual

Page 5

BROOKFIELD

5 of 9

\\Bvserver\Data\RS Information\SSTManual.doc

Getting Started In Soft Solids Testing

Two test methods are most often used to evaluate soft solids with the SST2000: The

Constant Rate Test and The Creep Test.

The Constant Rate Test

For products like: Stiff pastes, slurries, set gels, waxes.

Properties measured: Yield stress or torque, equilibrium stress strain at yield, rigidity

modulus.

Description: In the constant rate test the vane is rotated at a constant low rotational

rate (typically 0.1 to 0.5 rpm) and torque or stress is measured against time, rotational

angle or strain.

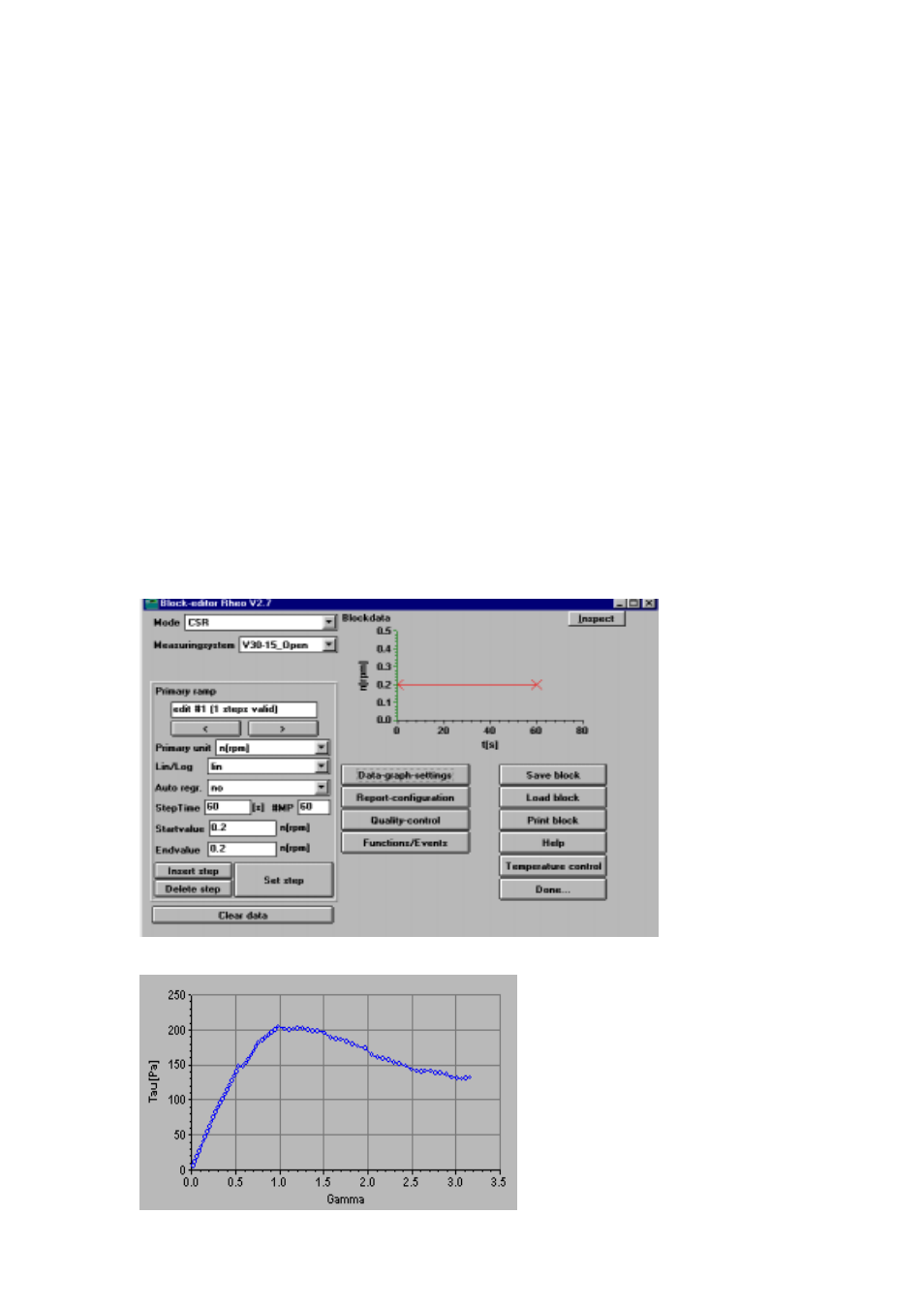

Example method: Constant rotation at 0.2 rpm, linear data collection, 60 data points

over 60 seconds. A V30-15 vane (30mm high by 15mm across) is used in an open

configuration (see Setting Up Vanes).

Typical results plots:

CR Test on mayonnaise with

stress (Tau, in Pascals) plotted

against strain (Gamma, unitless).

The peak value gives us yield

stress. The gradient of

stress/strain upcurve indicates gel

rigidity, a steeper curve: a stiffer

gel and vice-versa.