I.2 options, I.3 viscometer specifications, Viscometer specifications – Brookfield KU-1 Viscometer User Manual

Page 4: Can specifications

Brookfield Engineering Labs., Inc.

Page 4

Manual No. M/97-241-B1101

I.2

Options

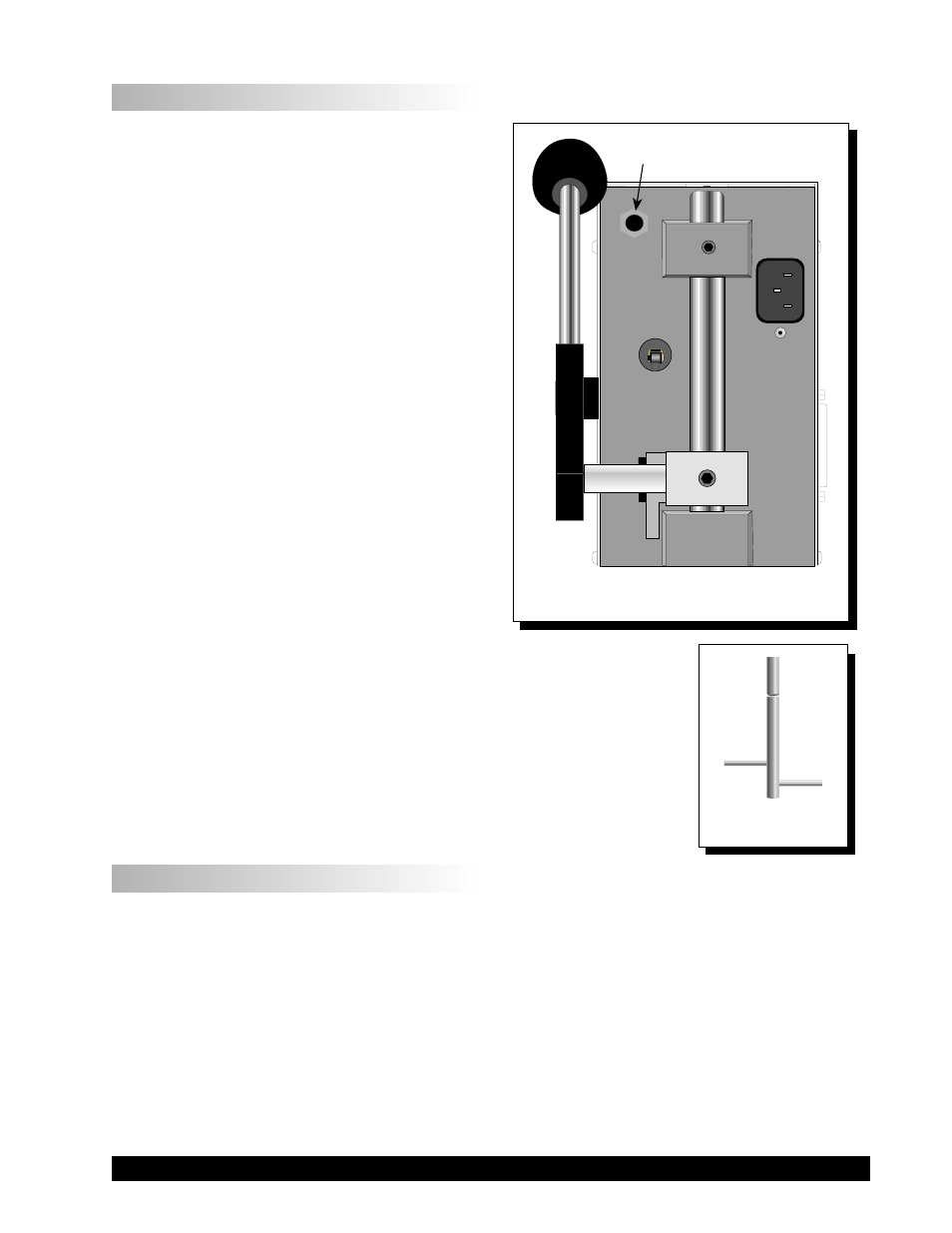

I.2.1 Air Purge

The air purge option (Brookfield Part No.

KU-1A) allows the interior of the KU-1+ to

be pressurized with air (or an inert gas) when

the instrument is to be used in a hazardous

environment (Figure 2). A built-in pressure

switch turns the instrument off when the

pressure drops below 2.0 PSI (falling). The

switch comes on at 10.0 PSI (rising).

Connect a regulated clean air supply which

is non-corrosive to brass to the fitting shown

in Figure 2. Adjust the pressure to approxi-

mately 25 PSI.

Note: The pressure switch range is 0-40 PSI.

DO NOT CONNECT PRESSURE HIGHER

THAN 40 PSI TO THE SWITCH!

I.2.2 Optional Paste Spindle

The paste spindle, Part No. KU1-75Y, (Figure 3) is a special spindle;

it is not included in a normal shipment/order. The design consists of

offset rod-type vanes, approximately 2 mm diameter x 19 mm long.

This spindle is suitable for use with high consistency materials such as

roller mill pastes. Do not use this spindle to report normal Krebs Unit

measurements. Record the grams value shown in the digital display

and note that the paste spindle was used to make the viscosity

measurement.

I.3

Viscometer Specifications

Range:

40–141 KU

32–1,099 gm

Accuracy:

±

1% of full scale range

Repeatability:

±

0.5% of full scale range

Paddle speed:

200 rpm

±

0.1 rpm

Printer output:

25D-Type Centronics Parallel Printer Output

Net weight:

22 lb. (10 kg)

Gross weight:

25 lb. (11 kg)

Dimensions:

15 x 11 x 20

Ambient conditions:

-20

°

C (-4

°

F) to 65

°

C (149

°

F)

Air Purge Fitting

Figure 3

Figure 2