Blue Sky Solar Boost 2512iX-HV User Manual

Page 5

Installation and Operation Manual

4

3-STAGE CHARGE CONTROL

The 2512 is factory configured for a 3-stage charging process, Bulk, Absorption and Float. The 3-stage charge process provides a somewhat higher

charge voltage to charge the battery quickly and safely. Once the battery is fully charged a somewhat lower voltage is applied to maintain the battery in a

fully charged state without excessive water loss. 3-stage charge improves battery performance and life while minimizing battery maintenance.

Bulk Charge

The 2512 will be in Bulk charge when battery voltage is below the Absorption Charge Voltage setpoint. During Bulk the 2512 delivers as much charge

current as possible to rapidly recharge the battery and drive battery voltage up to the Absorption Charge Voltage setpoint.

Absorption Charge

When the battery recovers sufficient charge for battery voltage to rise to the Absorption Charge Voltage setpoint (factory set to 14.2V) current is reduced as

necessary to hold the battery at the Absorption Voltage. The 2512 remains in Absorption until the battery is fully charged as determined by either;

1. The 2512 has remained in Absorption continuously for the Charge Time period (factory set to 2 hours).

– – – OR – – –

2. With the IPN-ProRemote display, net battery charge current while in Absorption decreases to the Float Transition Current setting (factory

set to 1.5A per 100 amp-hours of battery capacity).

Float Charge

Once the battery is fully charged a somewhat lower Float Voltage (factory set to 13.2V) is applied to maintain the battery in a fully charged state

without excessive water loss. During Float a healthy fully charged lead-acid battery will draw

≈0.1–0.2 amps per 100 amp-hours of battery capacity.

2-STAGE CHARGE CONTROL

Certain battery types or system configurations may require 2-stage charge control. The 2512 can be configured for two stage Bulk/Absorption charge

control by setting the Float charge voltage setting to No Float using the IPN-ProRemote or UCM. Refer to the IPN-ProRemote or UCM operators manual.

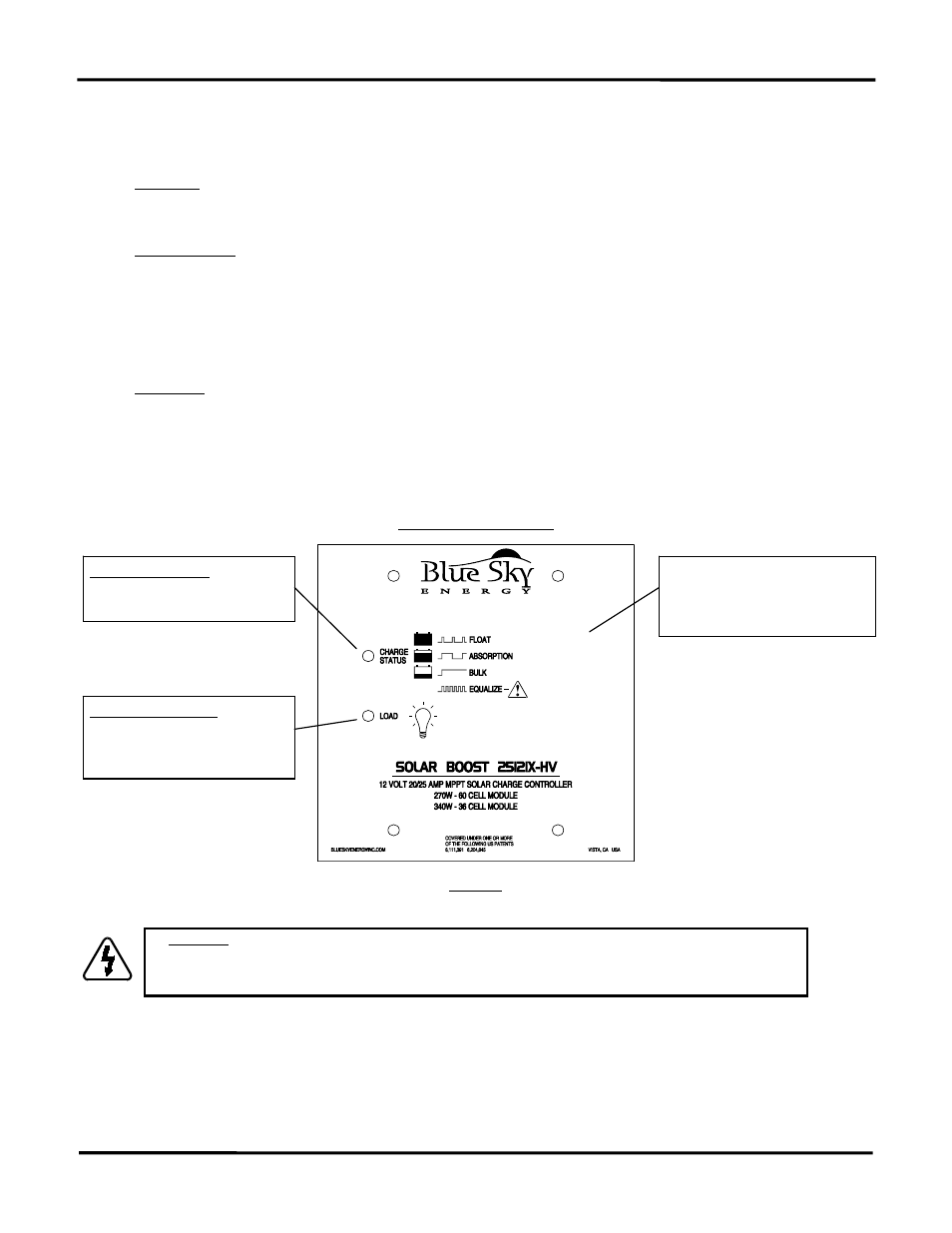

FRONT PANEL INDICATORS

FIGURE 1

EQUALIZATION (Omitted on SB2512i-HV)

¾

WARNING: Not all batteries can be safely equalized. Equalization should be performed only on vented liquid electrolyte

lead-acid batteries. Always follow battery manufacturers recommendations pertaining to equalization. Equalization applies a

relatively high voltage producing significant battery gassing. Disconnect equipment that cannot tolerate the high equalization

voltage which is temperature compensated as shown in Figure 2.

The 2512 can perform automatic equalization alone, or equalization may be controlled manually via the IPN-ProRemote or UCM. Equalization is

essentially a controlled overcharge which applies a relatively high voltage to bring all battery cells up to the same specific gravity. While equalization parameters

are adjustable with the IPN-ProRemote or UCM, factory default parameters of 15.2V for 2 hours every 30 days are suitable for most applications. A minimum net

charge current of approximately 3.5 amps per 100 amp-hours of battery capacity is required for proper equalization.

The equalization timer is a “time at voltage” time accumulator. The equalization timer will not count down unless battery voltage reaches the equalization

voltage setpoint. Unless manually canceled the 2512 will stay in equalize for as long as necessary to accumulate the required time at voltage. If equalize does not

complete by end of the charging day it will resume where it left off the next charging day. If equalize does not complete in a reasonable period of time due to

insufficient current it should be canceled manually via the IPN-ProRemote or UCM, or by momentarily removing power to reboot the 2512.

Charge Status Indicator

Shows present charge mode and

approximate battery state of charge.

Auxiliary Output Indicator

Shows when auxiliary output is ON for

load control or auxiliary battery charge.

Omitted in SB2512i-HV version.

The front panel serves as a heatsink for

power control devices. It is normal for

the front panel to be quite warm to the

touch when operating at high power.