Windy Nation Rover Marine Grade User Manual

Page 9

9

cable gland nut. It is important to firmly tighten the cable gland nut (See Figure 4 above)

because it supports the weight of the wires hanging down the tower. Failure to tighten the

cable gland properly could cause the tower wires to slip downward and put tension on the

three wires coming out of the generator. This could cause damage to the generator.

For towers over 25 feet tall, a stainless steel hose clamp needs to be firmly clamped

around the three tower wires directly above the cable gland nut (See Figure 4 above). Stainless

steel hose clamps can be purchased from local hardware stores. The hose clamp adds

secondary support so that the tower wires do not slip down the tower and put unnecessary

tension on the three generator wires. This is necessary for towers over 25 feet due to the

added wire weight in tall towers.

Next, connect the three tower wires to the three wires exiting the back of the

generator. Take great care in making sure these wire connections are strong and have good

continuity. It is highly advisable to cover these wire connections with outdoor rated heat shrink

tubing to prevent possible wire shorts and to protect the wire connections from the outdoor

elements.

Remember,

poorly

connected

wires

will

negatively

affect

the

power

performance

of

any

wind

turbine

and

will

lead

to

wire

connection

failure!

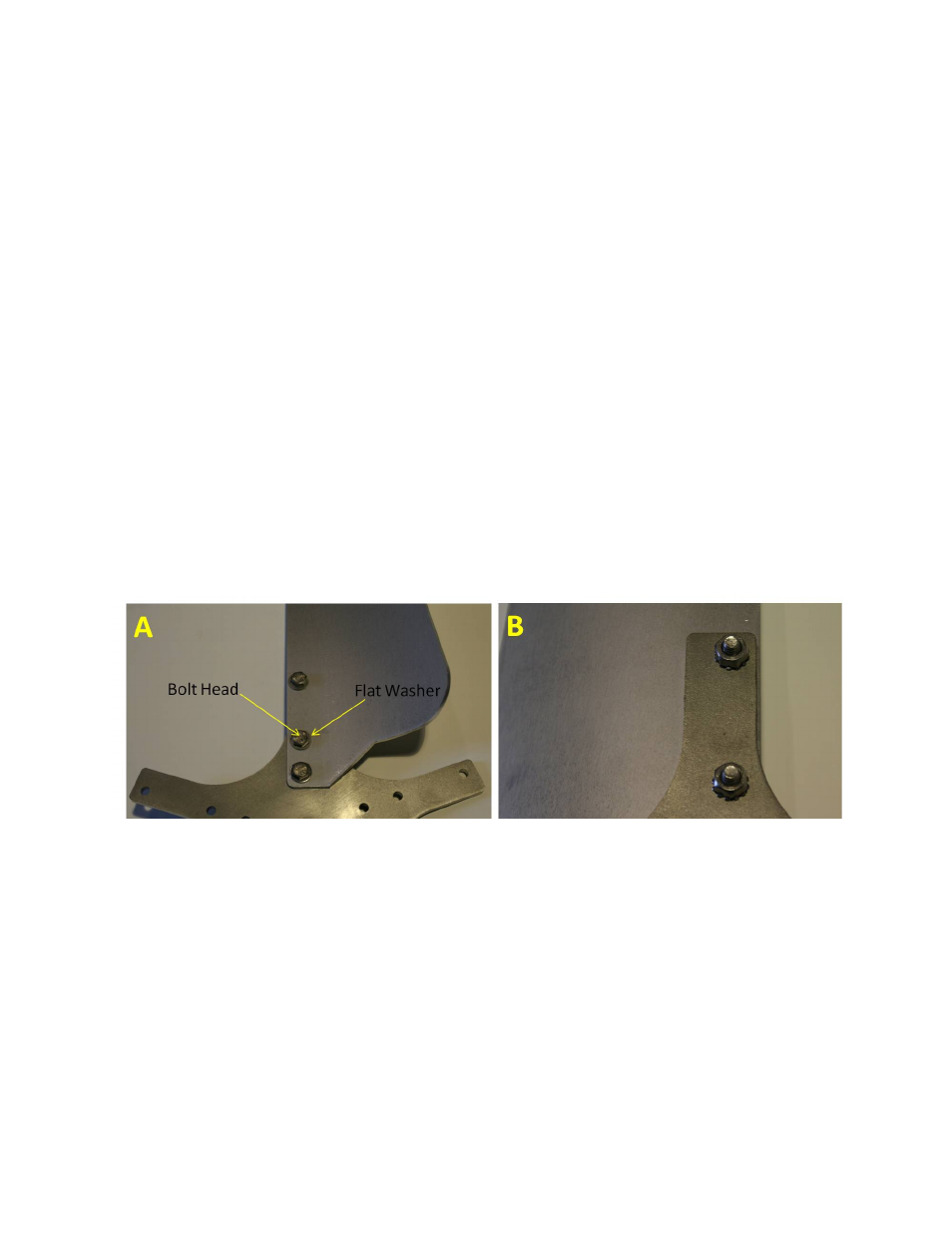

Section 3.0: Attaching the blades to the hub

Figure 5

Be

careful

not

to

hit,

bend

or

damage

the

blades

while

attaching

the

blades

to

the

hub

as

this

could

make

the

blades

unbalanced!

Note:

The

blades

should

be

mounted

so

that

they

curve

away

from

the

wind

turbine.

If

you

are

standing

in

front

of

the

wind

turbine

with

the

blades

facing

you,

the

blades

will

curve

outward

and

towards

you.

Step 1:

Locate the bag which is labeled “Blade to Hub Fastener Set”. This bag should contain

the following fasteners: 15 stainless steel bolts, 15 stainless steel k-‐lock nuts, and 15 stainless

steel flat washers.