Note – Yamaha pw80 User Manual

Page 37

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

If beyond tolerance replace piston or rebore

cylinder as required.

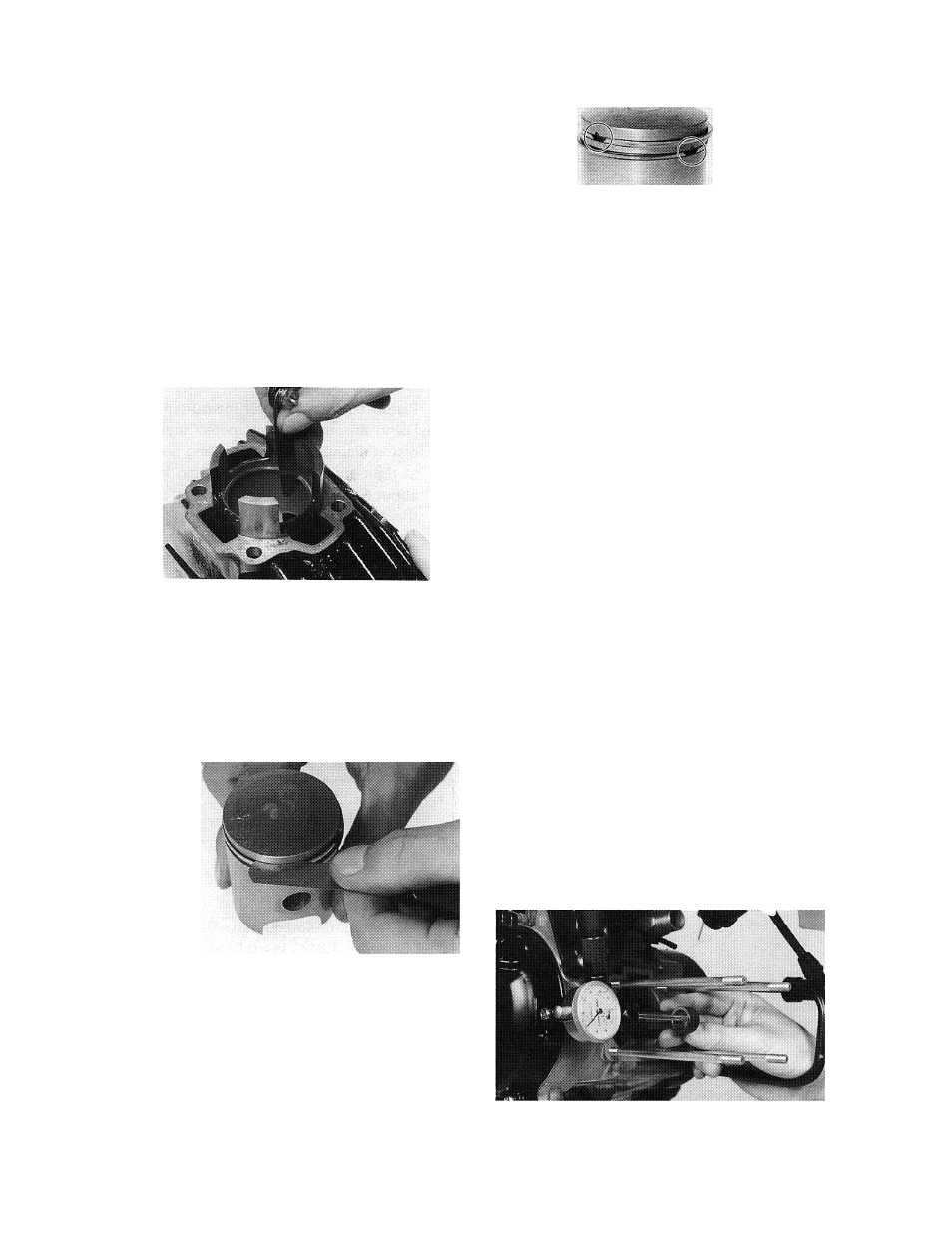

Piston rings

1. Remove ring from piston.

2.

Insert ring into cylinder. Push down ap

proximately 20 mm (0.79 in) using piston

crown to maintain right-angle to bore.

Measure installed end gap. If beyond

tolerance, replace.

Ring end gap installed (top and 2nd):

0.15-0.35 mm (0.006-0.014 in)

3.

With rings installed in grooves, insert

feeler gauge between ring and groove. If

beyond tolerance, replace ring and/or

piston as required.

Ring groove clearance:

0.020-0.060 mm (0.0008-0.0024 in)

4.

5.

Holding cylinder towards light, check for

full seating of ring around bore. If not fully

seated, check cylinder. If cylinder is not

out-of-round, replace piston ring.

During installation, make sure ring ends

are properly fitted around ring locating pin

in piston groove. Apply liberal coating of

two-stroke oil to ring.

NOTE: ------------------------------------------

New rings require break-in. Follow first portion

of new machine break-in procedure.

Piston pin bearing and connecting rod

1.

Check the pin for signs of wear. If any

wear is evident, replace pin and bearing.

2.

Check the pin and bearing for signs of

heat discoloration. If excessive (heavily

blued), replace both.

3.

Check the bearing cage for excessive

wear. Check the rollers for signs of flat

spots. If found, replace pin and bearing.

4.

Apply a light film of oil to pin and bear

ing surfaces. Install in connecting rod

small end. Check for play. There should

be no noticeable vertical play. If play ex

ists, check connecting rod small end

diameter for wear. Replace pin and bear

ing or all as required.

5.

Mount the dial gauge at right angles to

connecting rod small end holding the bot

tom of rod toward the dial indicator, rock

top of rod and measure axial play.

Connecting rod axial play:

1.0 mm (0.04 in)

-25-