Dynon Avionics RV-10 Pitch Legacy User Manual

Page 3

DYNON AVIONICS

Servo Mounting Instructions – RV-10 Pitch Kit

2

101046-006 Rev F

SERVO MOUNTING INSTRUCTIONS – RV-10 PITCH KIT

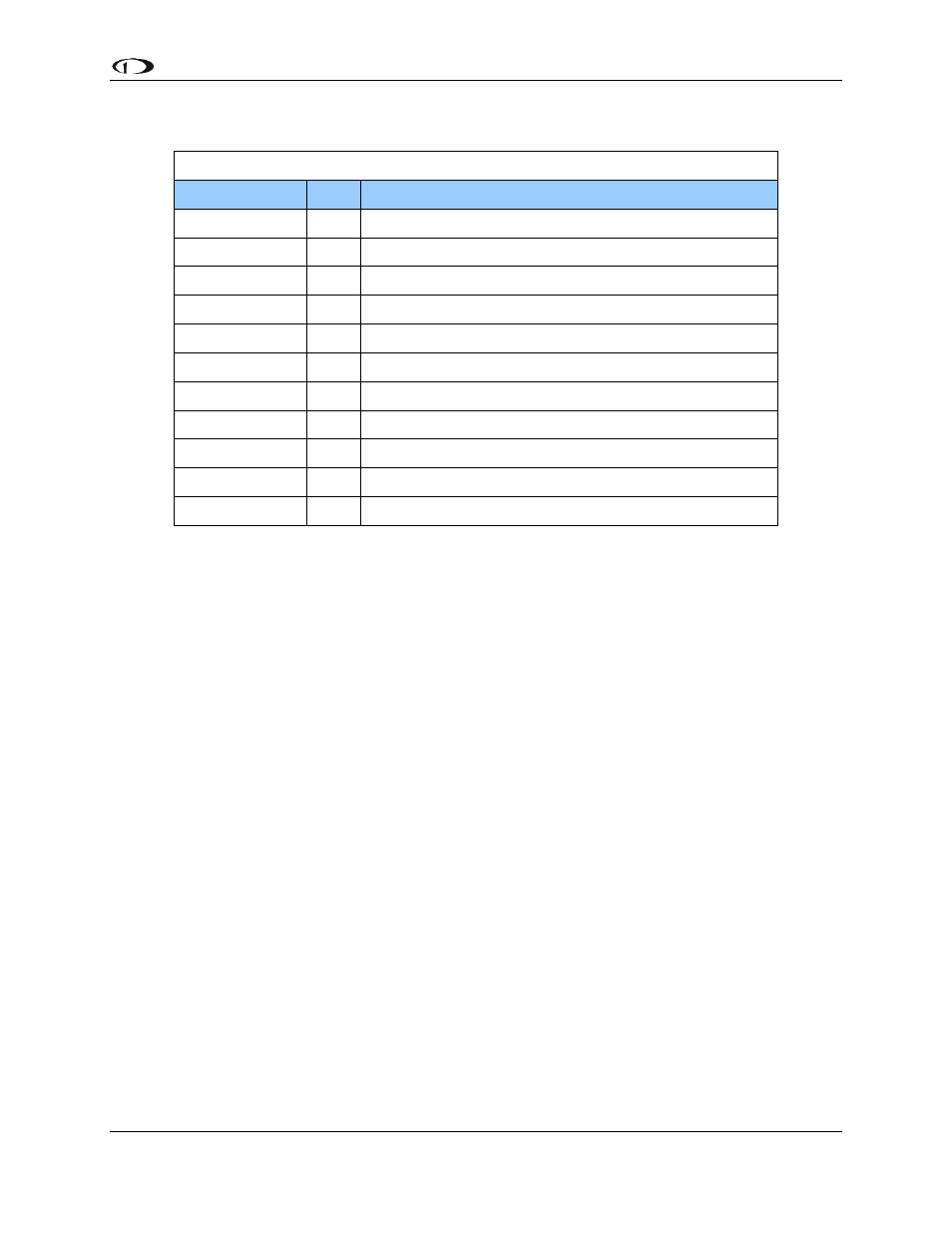

Kit Contents

Dynon Part # QTY Part Description

100836-000

2

Large Male Rod End

100966-008

1

Aluminum Pushrod Tube – 3.0”

100973-000

1

RV10 Pitch Bracket

100975-002

2

AN315-4R Jam Nut

100976-011

2

AN365-1032A Nylon Insert Locknut

100977-000

2

AN970-3 Large Flat Washer

100978-003

10 AN960-10 Small Flat Washer

100979-002

4

MS35333-39 #10 Internal Star Washer

100981-000

4

AN3H-3A Bolt - 3/8"

100981-005

1

AN3H-10A Bolt - 1"

100981-006

1

AN3H-11A Bolt – 1 1/8"

The RV-10 pitch servo mounting kit includes a mounting bracket, pushrod linkage, and most of the

required fasteners to mount the servo and properly link it to the aircraft control system. All Dynon-

supplied parts are illustrated in dark grey to distinguish them from existing aircraft hardware. Refer

to the drawing to locate the servo mounting bracket in the aircraft.

Fasteners along the mounting plate surface must be removed and can be re-used to secure the

bracket in place. The Dynon mounting bracket must be drilled to match the existing hole pattern of

the aircraft plate. Once the bracket has been drilled, fasten it to the aircraft. It is up to the installer

to verify the hardware used is tightened back to aircraft specification.

With the bracket installed in the aircraft, the bell crank must be drilled. Refer to the drawing for

dimensions, and use a supplied AN960-10 washer as a support between the two halves of the bell

crank to avoid crushing when the linkage is fastened.

Install the 4 AN3H-3A bolts, MS35333-39 star washers, and AN960-10 flat washers to secure the

servo to the bracket per the drawing, noting the orientation of the servo output arm. All AN bolts

supplied by Dynon have drilled heads for use with safety wire. With the servo and bell crank

additions in place, torque all fasteners back to original installation specifications and add safety wire

where needed.

With the servo installed, the linkage needs to be assembled. Refer to the illustration and follow

proper rod end installation techniques. Thread both large rod ends with jam nuts into the supplied

3.0" tube. Mounting of the linkage to the servo arm will include the AN3H-10A bolt, AN970-3 large

diameter flat washer (for capturing the rod end bearing), 2 AN960-10 flat washers, and the AN365-

1032A lock nut. The other end of the linkage will require the same type of stack-up, using the longer

AN3H-11A bolt and capturing the washer sandwiched between the halves of the bell crank.

To prevent the possibility of the servo arm going over-center, the servo arm must not travel more

than a total of +/-60º from neutral throughout the control system's range of travel. The linkage