Warning – Bradford White EF-100T-399-3X User Manual

Page 10

10

238-50320-00A 3/13

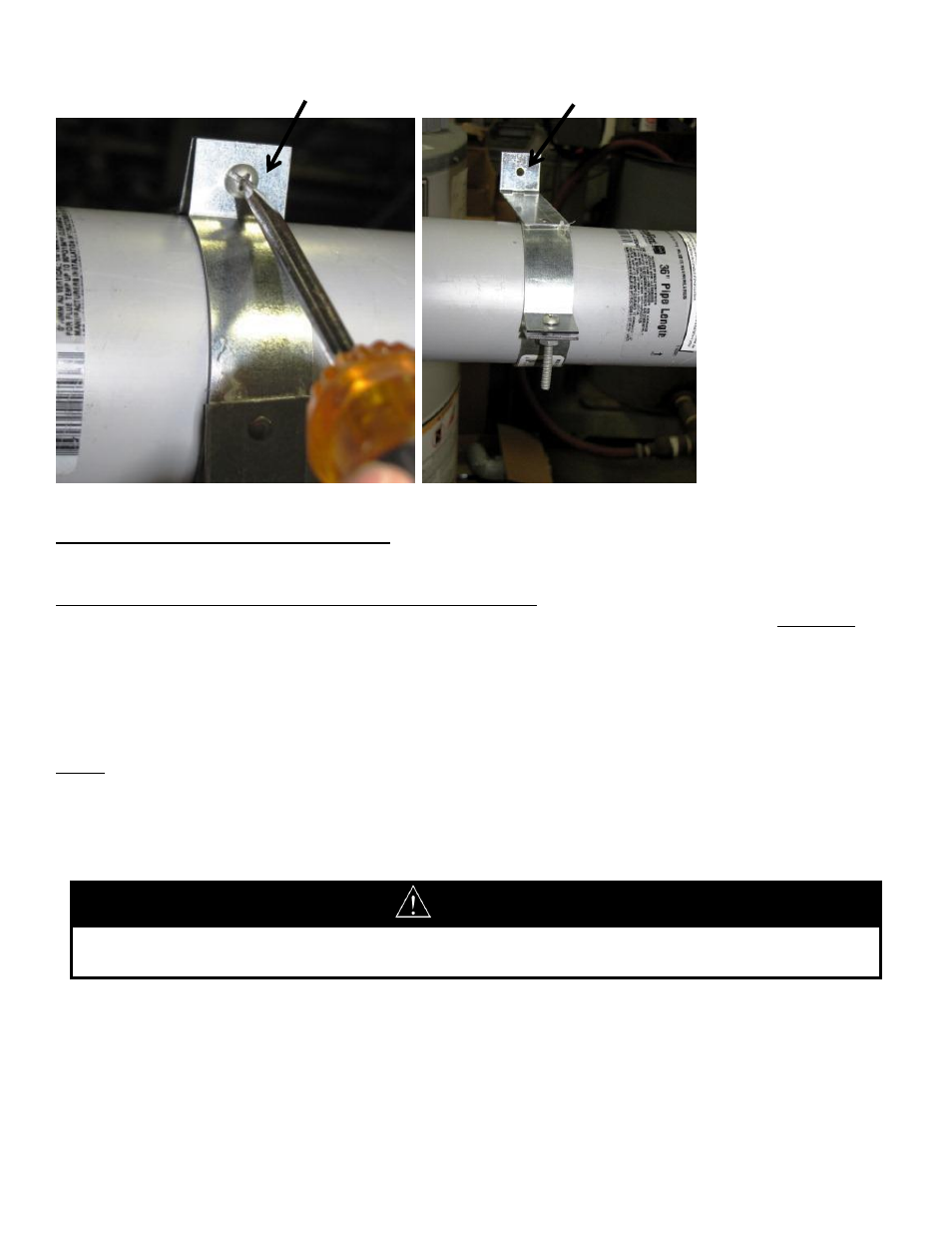

Tighten Metal Clamp around body of vent pipe. Metal clamp fastens to wall with wood screws

High Efficiency Commercial Condensing Models:

For horizontal sections of flue pipe, the pipe must be installed with a slight upward slope of approximately ¼ inch per

foot (20 mm per meter) toward the water heater to allow condensate to drain into the condensate elbow.

Residential and Commercial Power Direct Vent / Power Vent Models:

To prevent condensate from accumulating in the exhaust blower, install the horizontal vent pipe with a downward slope

toward the vent terminal of ¼ inch per foot (20 mm per meter) of horizontal vent pipe. An optional condensate kit is

available for residential power vent models or a tee fitting with a condensate drain loop may be used on commercial

power direct vent models to prevent condensate accumulation in the blower for long vertical runs of vent pipe. Refer to

the venting section of the Installation and Operating Instructions supplied with the water heater.

Step 6: If any of the straight pipe sections need to be cut, use a hack saw and make a straight cut on the male

(ungasketed) end of the pipe. When making the cut, allow for the 2” minimum (51 mm) insertion distance inside the

female end of the pipe. Make sure the cuts are made square and use a razor knife to deburr the edges of the cut pipe to

avoid any sharp edges that may damage the gasket.

DuraVent has adjustable vent pipe sections available, which allow 4.5 inches (114 mm) of adjustment to the length.

WARNING

Cut pipe edges must be properly deburred. Damage to the gasket from not deburring the edges of the cut male

end may result in the release of dangerous flue products.

- EF-100T-300-3X EF-100T-250-3X EF-100T-199-3X EF-100T-150-3X EF-60T-199-3X EF-60T-150-3X EF-60T-125-3X EF-100T-399E-3N EF-100T-300E-3N EF-100T-250E-3N EF-100T-199E-3N EF-100T-150E-3N EF-60T-199E-3N EF-60T-150E-3N EF-60T-125E-3N PDV-100S-250-3N PDV-100S-200-3N PDV-100S-150-3N PDV-80S-250-3N PDV-80S-200-3N PDV-80S-150-3N PDX-75S-70FB-3N PDX-65S-65FB-3N PDX-50S-60FB-3N TW4-75S-76B-3N TW4-65S-70FB-3N TW4-50S-67FB-3N TW-55X-78B-3N TW-25X-76B-3N PDX2-75T6FSX PDX2-65T6FSX PDX2-50T6FSX PDX4-50S6FSX PDX4-40S6FSX PDX1-50S6FSX PDX1-40S6FSX M-4-XRTW65T6FSX M-4-XRTW50T6FSX M-2-TW-75T6SX M-2-TW-65T6FSX M-2-TW-50T6FSX M-4-TW60T6FSX M-4-TW50T6FSX M-4-TW40T6FSX M-1-TW-60T6FSX M-1-TW-50S6FSX