Planning and configuring the system, Connectors and grounding, Using the switch inputs – Allen&Heath DR Switch User Manual

Page 3

DR-switch User Guide AP4493

3

Important: Using the Switch Inputs and Logic Outputs

The DR-switch provides contact closure switch inputs and open-collector logic outputs. How these are wired to

external equipment is the responsibility of the installer. Specification details are provided here for the DR-

switch inputs and outputs. It is important that the installer is suitably qualified and familiar with external control

circuits to be able to work within the capabilities of the unit. Allen & Heath do not assume responsibility for any

damage done to the unit due to incorrect or faulty connection to external equipment.

Planning and Configuring the System

Before starting make sure you have planned how the system is to work. Allocate the switch inputs and logic

outputs and keep a log of their function. The function of each input and output is configured using the Allen &

Heath WinDR software. Refer to the help file within the program for instructions.

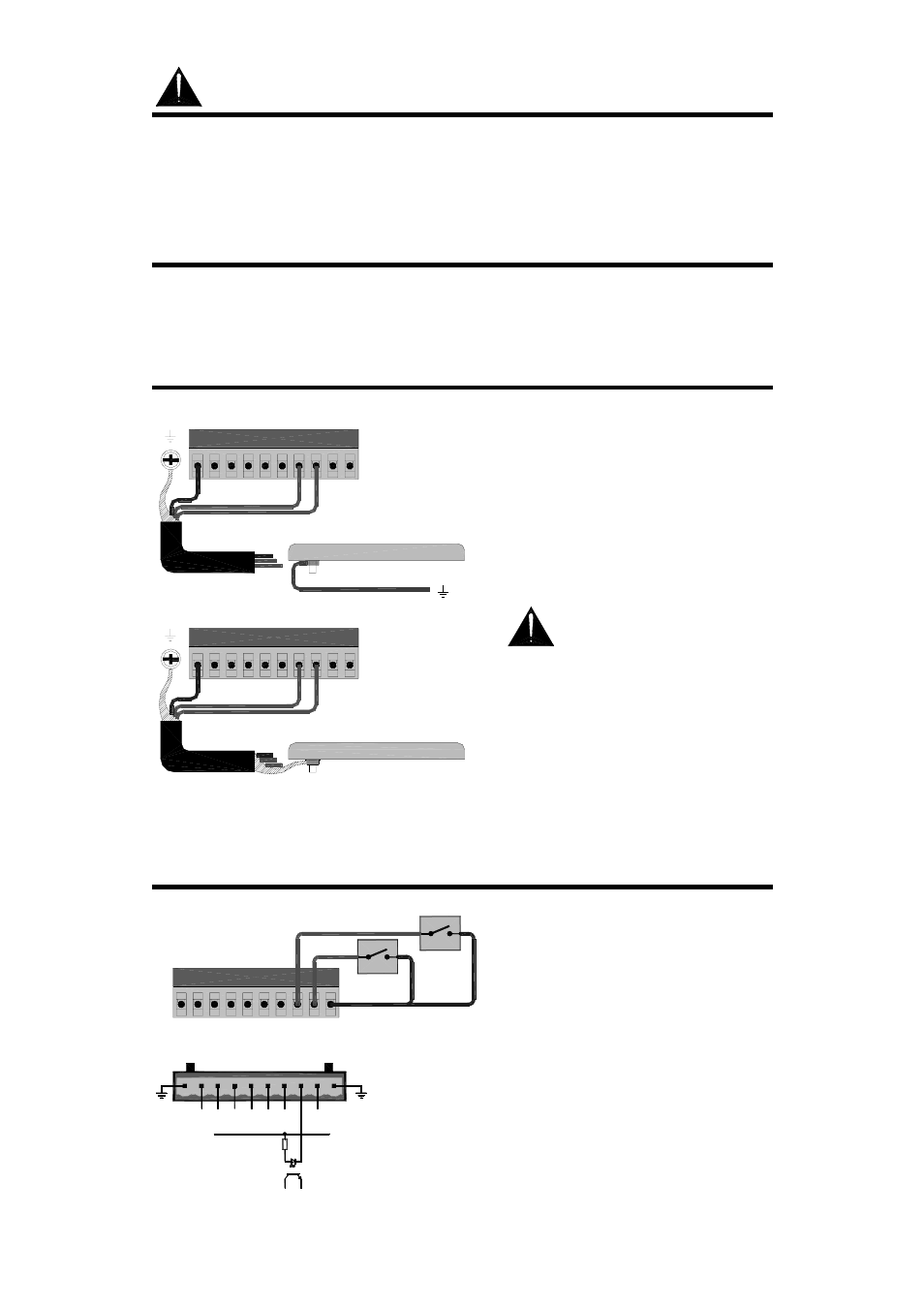

Connectors and Grounding

Using the Switch Inputs

Pluggable Phoenix type screw terminal

connectors are used for connecting the

external switches and logic to the DR-switch.

Mating plugs are provided with the unit.

Make sure the wires ends are carefully stripped

and inserted into the terminals. Tighten the

screws using the correct slotted screwdriver.

To ensure interference-free operation use

shielded cable. Connect the shields to the

chassis ground screw terminals provided next

to each connector. Fit the screws with the

shake proof washers provided.

For operator safety make sure that

wall plates and other control surfaces made

from metal are correctly bonded to ground

(earth).

Strap the metal plate to the local ground at the

wall box. For ground isolation between the

wall plate and equipment rack connect the

cable shield at the DR-switch end only.

If a local ground is not available then use the

cable shield to connect the plate to the chassis

of the DR-switch unit as shown. This is not

necessary if the wall plate is made of non-

conductive material such as plastic which

insulates it from the operator.

G

METAL WALLPLATE

CHASSIS EARTH

G

METAL WALLPLATE

LOCAL EARTH BOND

SWITCH

SWITCH

4

3

2

1

5

6

7

8

G

G

12 11 10 9

13

14

15

16

G

G

20 19 18 17

21

22

23

24

G

G

INPUTS

2K2

+10V

OPTO

INTERNAL DR-switch CIRCUIT

(1 OF 8 SHOWN)

The input is opto-coupled to isolate the DR-

switch from the connected equipment. It is

switched by linking its connector pin to the

ground (‘G’) pin. Use a contact closure such

as a momentary press switch to do this.

The input pin is fed from the internal +10V

reference supply through a 2k2 ohm resistor.

Around 5mA maximum current flows when

connected to ground. Combined switch and

cable resistance should not exceed 1k ohm for

the switch to activate.

Each 10way connector provides 8 switch

inputs. Either pin 1 or pin 10 ‘G’ may be used

as the common switch ground. One cable can

feed this ground to a bank of switches. Two

are shown in the diagram here. Do not use the

chassis ground screw which is for cable

shielding and safety earthing only.

For reliable operation we recommend the use

of heavy duty sealed switches.