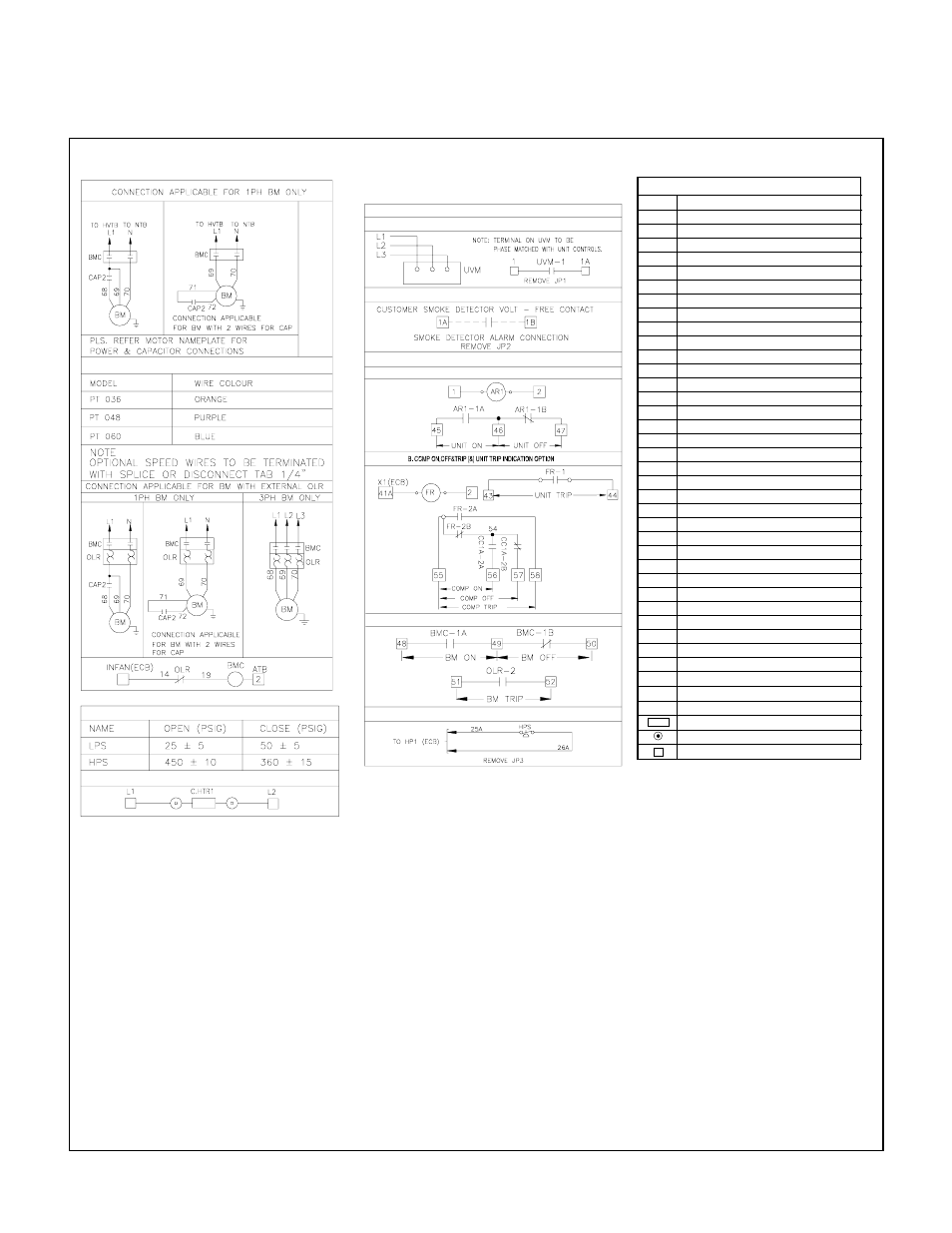

Typical schematic wiring diagram – Cooline PT036L User Manual

Page 24

2. SMOKE DETECTOR OPTION

CRANKCASE HEATER CONNECTION

4. HPS CONNECTION OPTION

STANDARD OPTIONS

1. UVM OPTION

3. VOLT FREE CONTACT OPTIONS

A. UNIT ON & OFF INDICATION OPTION

C. BM ON,OFF & TRIP INDICATION OPTION

PRESSURE SWITCH SETTINGS

TO HVTB

TO NTB

*

TO HVTB

*

TO NTB

FACTORY INSTALLED B.M SPEED

*

*

*

TYPICAL SCHEMATIC WIRING DIAGRAM

MODELS : PT036 - PT075 (Single compressor units)

LEGEND

AR

AUXILIARY RELAY

AFS

AIRFLOW SWITCH

ATB

AUXILIARY TERMINAL BLOCK

BM

BLOWER MOTOR

BMC

BLOWER MOTOR CONTACTOR

CC

COMPRESSOR CONTACTOR

CCA

AUXILIARY CONTACT

CB

CIRCUIT BREAKER

C. HTR CRANKCASE HEATER

COMP

COMPRESSOR

ECB

ELECTRONIC CONTROL BOARD

FCS

FAN CYCLING SWITCH

F

FUSE

FL

FUSE LINK

FM

FAN MOTOR (CONDENSER)

FMC

FAN MOTOR CONTACTOR

FR

FAULT RELAY

HC

HEATER CONTACTOR

HPS

HIGH PRESSURE SWITCH

HVTB

HIGH VOLTAGE TERMINAL BLOCK

HTR

HEATER

JP

JUMPER

L1

LINE 1

L2

LINE 2

L3

LINE 3

LPS

LOW PRESSURE SWITCH

LUG

LUG GROUND

NTB

NEUTRAL TERMINAL BLOCK

O/L

OVER LOAD

OHT

OVER HEAT THERMOSTAT

PDS

PUMP DOWN SOLENOID

SSPS

SOLID STATE PROTECTIVE SYSTEM

SD

SMOKE DETECTOR

TRANS TRANSFORMER

T'STAT THERMOSTAT

UVM

UNDER VOLTAGE MONITOR

FIELD WIRING

DISCONNECT TAB - 1/4"

SPLICE-CLOSED END

TERMINAL BLOCK OR TERMINATION POINT

_ _ _

+

NOTES

1. POWER SUPPLY, 380/415V-3PH-50Hz.

2. ANY WIRE REPLACEMENT SHOULD BE OF 90

0

C OR ITS

EQUIVALENT. USE COPPER CONDUCTOR WIRES ONLY.

3. IF PDS & HEATERS ARE FACTORY INSTALLED, PLEASE

READ BROKEN LINES AS CONTINUOUS LINES.

4. POWER MUST BE SUPPLIED TO CRANKCASE HEATER FOR

MINIMUM OF 12 HOURS PRIOR TO SYSTEM START UP.

IF POWER IS OFF 6 HOURS OR MORE, CRANKCASE

HEATER MUST BE ON FOR 12 HOURS BEFORE OPER-

ATING THE SYSTEM.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RE-

SULT IN COMPRESSOR DAMAGE.

5. FUSED DISCONNECT SWITCH OR CIRCUIT BREAKER

TO BE PROVIDED BY CONSUMER WITH RATING AS

RECOMMENDED BY COOLINE.

6. COMPRESSOR IS PROVIDED WITH INTERNAL OVERLOAD.

7. IF ANY CHANGE IN DIP SWITCH SETTING IS REQUIRED,

TURN OFF POWER FIRST & SET REQUIRED SETTING.

23