Craftsman CONTRACTOR 351.21833 User Manual

Page 11

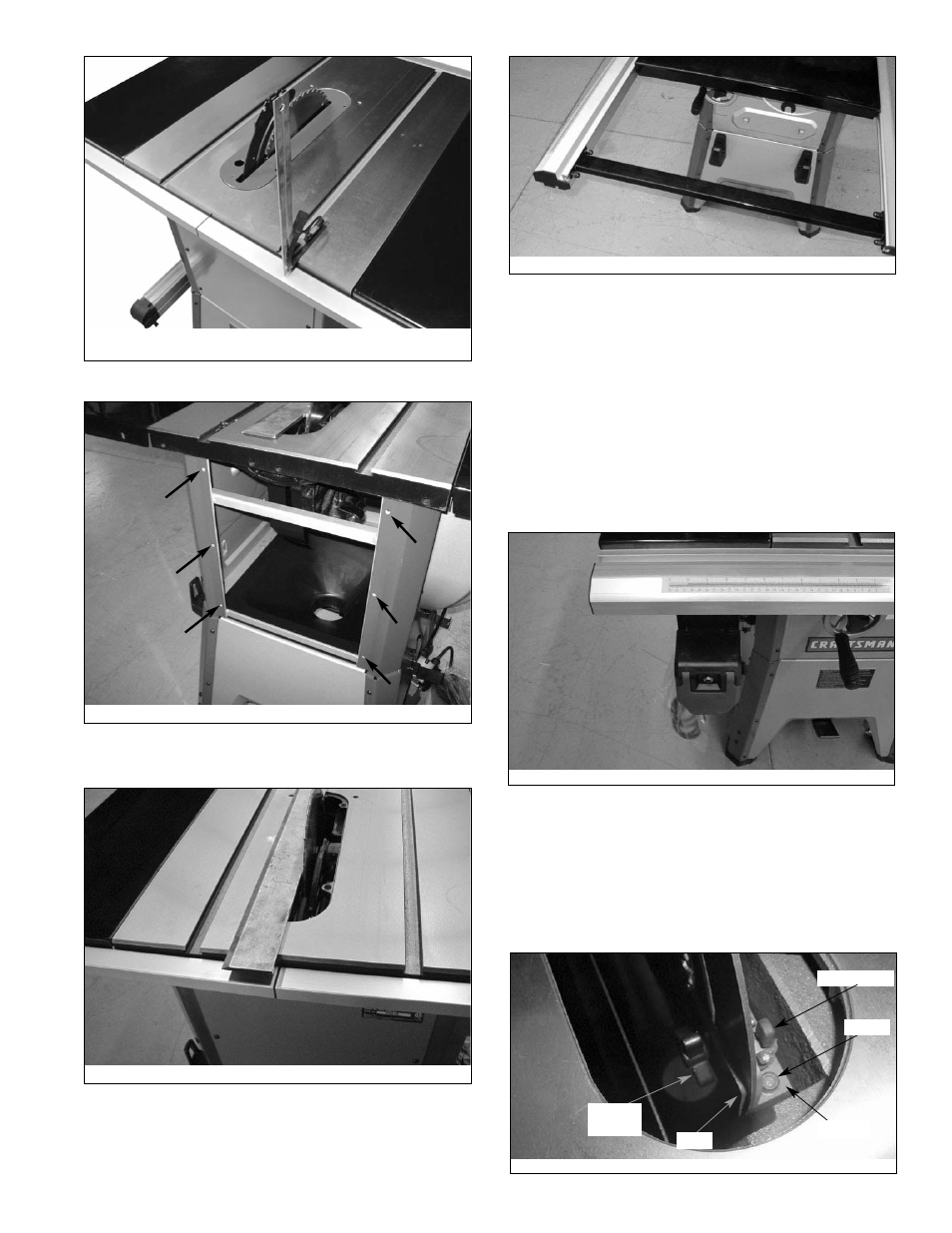

• Loosen and remove six socket pan head screws and the

back panel. This will allow easier attachment of the rear rails.

• Install the rear rails in the same manner as the front rails

and align the rail joint to the blade.

• Replace back panel of the cabinet.

• Insert M8 x 20 hex bolts through holes in bracket at each

end of brace. Attach brace to the far right end of the rails

by sliding hex bolts into the rail T-slots. Secure bolts in

position with flat washers, lock washers and nuts.

ATTACH SWITCH ASSEMBLY

Refer to Figure 30.

Tools Required: 10mm Open end Wrench

Hardware Required: Two M6 x 16 hex head bolts, two M6 flat

washers, two M6 lock washers and two M6 hex nuts.

(Hardware bag #3).

• From above switch assembly bracket, insert two bolts

through bracket holes.

• Loosely attach flat washer, lock washer and nut to bolts.

• Insert bolt heads into T-slot on bottom of left front rail.

• Slide switch assembly 6

″ to 8″ from left end of rail as

shown in Figure 30.

• Fully tighten flat washers, lock washers and hex nuts to

secure switch assembly in place.

POSITION AND ADJUST RIVING KNIFE

Refer to Figure 31.

• Riving knife is installed on the saw. Raise the blade com-

pletely to access the riving knife.

• Loosen the locking knob and raise the riving knife to its

highest position. Riving knife has three holes for three posi-

tions. The highest position is for all thru cuts. The middle

position is for rabbets and other non-thru cuts, (with guard

and pawls removed). The lowest position is for dado cuts.

11

Figure 26 - Check parallelism of rails to table with combination

square. Check at several locations along rail.

Figure 27

Figure 28

Figure 29

Figure 30

Figure 31 - Riving Knife

Locking Pin

Bracket

Plate

Locking

Knob

Screw