Wine-Mate SSHWC Series User Manual

Page 20

- 19 -

4) There is a gravity drain system used, so the unit shall be installed level or with

a slight slope downward the drain connection and the drain line shall be

installed slope down toward the drain. If rise-up is needed, a condensation

pump must be used.

4. Condensing Unit Installation

1) Condensing unit shall be elevated to avoid possible flooding and shaded from

direct sun. The location shall be adequately ventilated and shall not be

subject to freezing temperatures.

2) Water must be supplied to WM-250~850SCU-WC at all times during

operation, with the maximum outlet temperature of 120 °F. A sufficient

amount of water must be provided for constant head pressure and proper

cooling, but excessive water flow will cause the unit working inefficiently.

3) The maximum permissible water pressure is 150 PSIG. If water pressure is

excessive, a pressure reducing valve must be used to reduce the water

pressure.

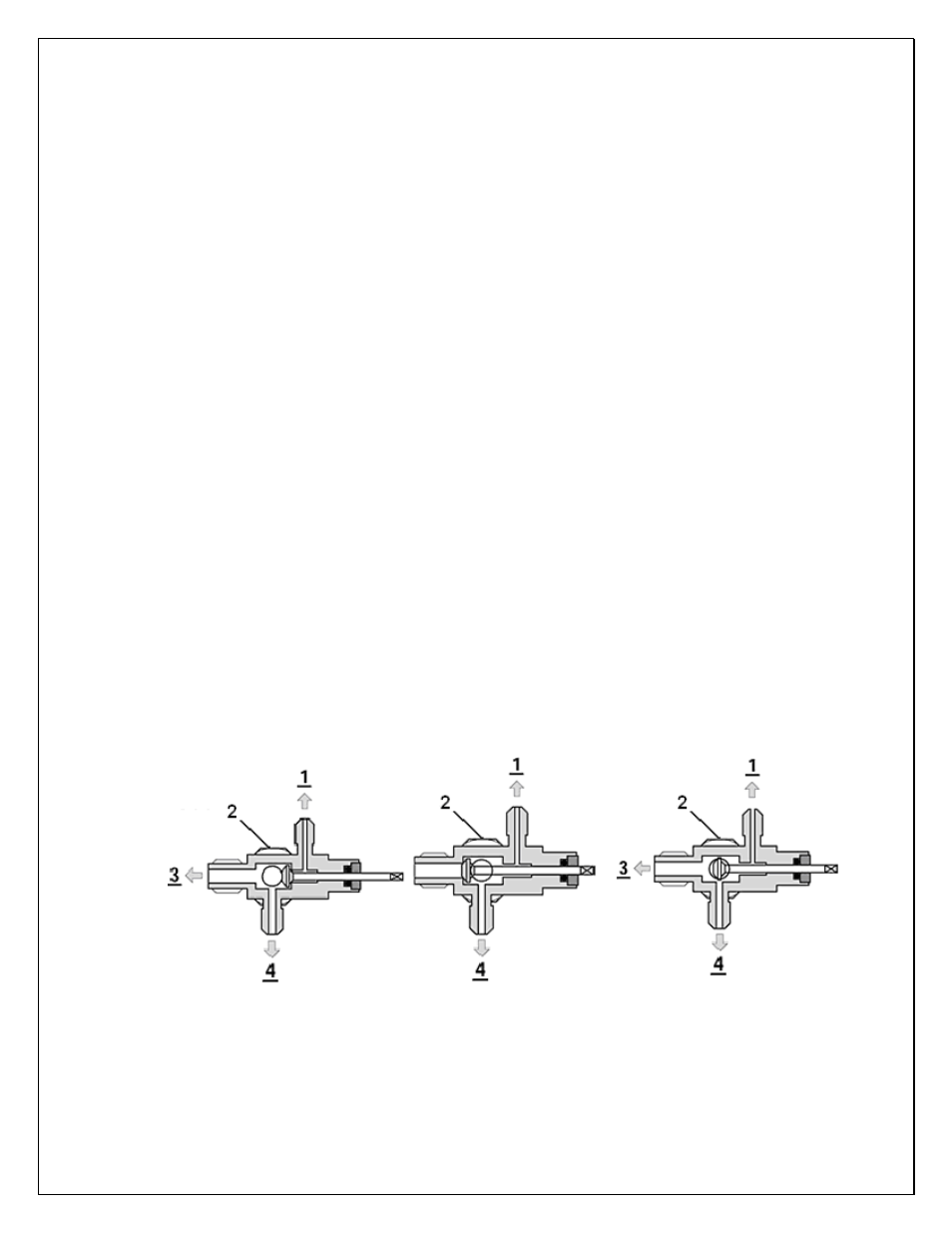

4) Service valve operation

1 - Process or Manometer

2 – Receiver Discharge or Compressor Suction

3 – Liquid Line or Suction Line

4 - Pressure Control

Back Position: Normal operation after installation is complete, process or

manometer port is closed.

Front Position: Storage or shipping operation, liquid or suction line connection

is closed.

Middle Position: Installation operation, all ports are open for evacuation, charge

and manometer.

BACK POSITION FRONT POSITION MIDDLE POSITION

Fig. 8 ROTALOCK Valve Operation