Assembly – Symtech CVA 3 With Line Laser User Manual

Page 5

5

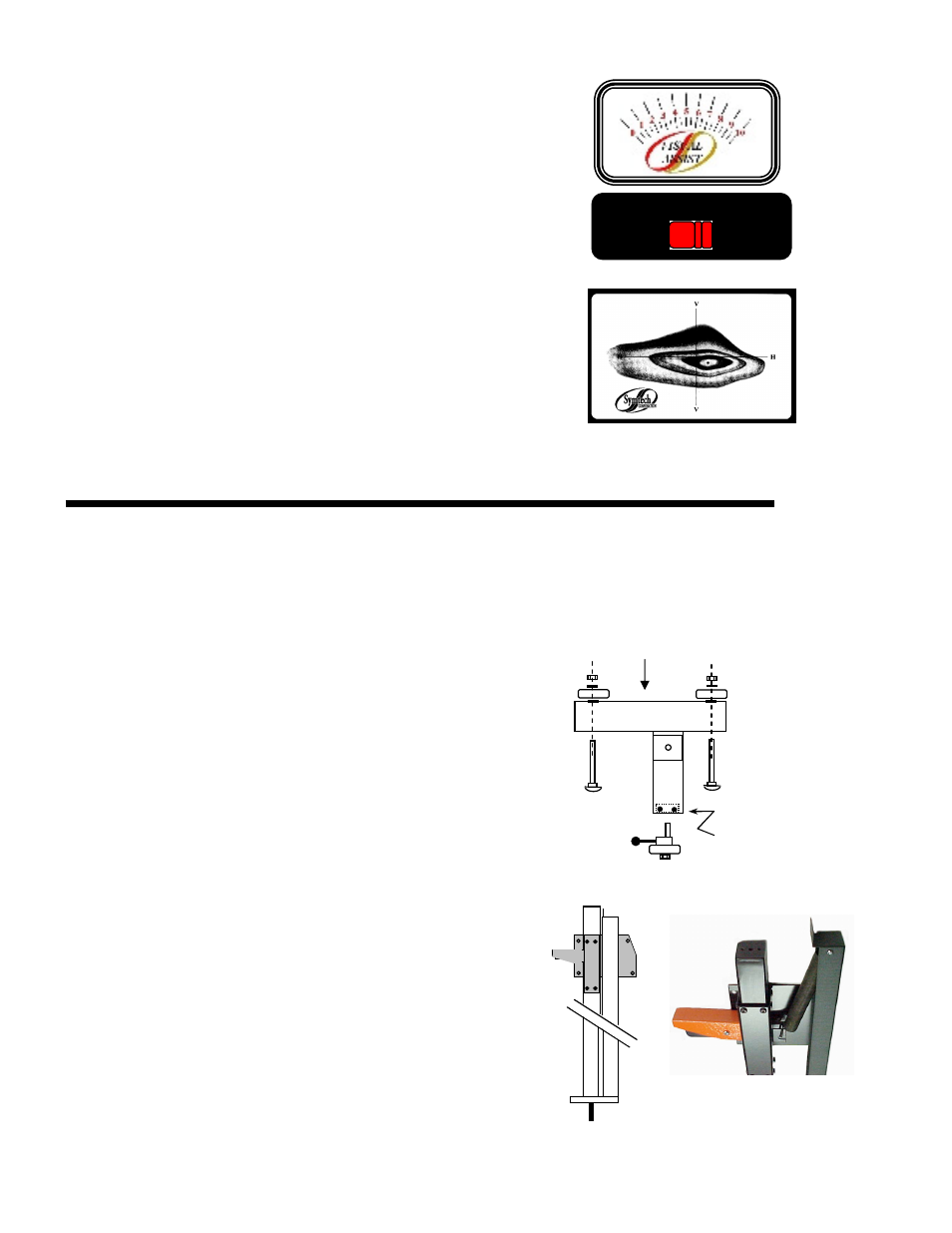

1.5 VISUAL ASSIST METER & SWITCH

The “Visual Assist” meter is an aide for positioning the headlamp

pattern to its correctly designed position. While visually adjusting

the headlamp into position, the “Visual Assist” meter will raise in

numeric reading if adjustment is directed in the correct direction.

Adversely, the meter reading will decrease if headlamp is adjusted in

the incorrect direction. When the highest achievable reading is

attained both vertically and horizontally, the headlamp will be

positioned correctly.

The SELECTOR switch moves the “Visual Assist” meter function

between High and Low Beam patterns. Make sure that the switch is

in the correct location for the beam pattern to be aligned.

1.6 ISO

Color LAMP PATTERN DEFINITION

ISO

Color technology, unique to Symtech Products, colorizes the

lamp pattern by designating a hue to the intensities of the headlamp.

The headlamp pattern will appear on the screen with the highest

intense portion of pattern being the most inner circle of color, with

varying colors of intensity radiating outward.

2. ASSEMBLY

Inspect all components of the CVA 3

EZ

EZ

EZ

EZ

system to assure that no damage has occurred during shipment, compare

contents of package with that of the exploded view to make sure that no component has been inadvertently left out of

packaging. If a component is missing, contact our customer service department at 888-884-8182 for an immediate

replacement.

2.1 BASE / WHEEL ATTACHMENT

Place base of system on floor, or table with channel facing

downward.

Insert a 5/16” x 6” carriage bolt into each of the holes noted, making

sure that the square carriage bolt head seats securely into the square

hole placement.

Complete wheel assembly by placing in order a large nylon washer,

wheel, small nylon washer and self-locking 5/16” nut on carriage

bolt.

Tighten self-locking nut snug against wheel, but not so tight as to

hinder free wheel movement.

Insert floor slope eccentric and wheel into mounting block on base

(rear wheel). Tighten friction bolt until floor slope eccentric can be

moved, but not loose enough to move by itself.

2.2 MAST / GLIDE PLATE / ROTATIONAL MAST MOUNT

The Mast, Counterweight Spring Cover and Spring are packaged as

an assembly.

Remove attachment screw at top of mast spring cover.

Slide Glide Plate over end of mast, between mast and mast spring

cover, ensuring that handle is pointed away from spring cover. Slide

glide plate down over mast until the spring hook of the glide plate is

even with the bottom of the spring inside of the mast spring cover.

Place bottom of spring into spring hook, and reattach screw at top of

mast spring cover.

Place rotation bearing over mast stud and insert rotational mast stud

into base. Secure mast to base with

1

/

2

” flat washer and ½” self-

“HIGH”

BEAM

“LOW”

BEAM

VISUAL ASSIST SELECTOR

Tighten

this Bolt

Front of Base